发电技术 ›› 2025, Vol. 46 ›› Issue (1): 126-134.DOI: 10.12096/j.2096-4528.pgt.24032

• 发电及环境保护 • 上一篇

卢文强1,2, 陈岩3, 付经伦2,4,5, 刘海松3, 孔祥玲5

收稿日期:2024-02-24

修回日期:2024-05-18

出版日期:2025-02-28

发布日期:2025-02-27

作者简介:基金资助:Wenqiang LU1,2, Yan CHEN3, Jinglun FU2,4,5, Haisong LIU3, Xiangling KONG5

Received:2024-02-24

Revised:2024-05-18

Published:2025-02-28

Online:2025-02-27

Supported by:摘要:

目的 燃气轮机设计加工过程中,部件几何结构和运行条件存在着许多不确定性,从而引起燃机热力性能的显著波动。为了准确辨识燃机运行状态,需要定量评估这种不确定性对关联部件及整机总体性能的影响。 方法 基于蒙特卡罗方法和燃气轮机热力过程机理方程组,建立燃气轮机总体性能不确定性分析模型,研究部件效率、流量不确定性的定量传播特性。针对航改燃机结构,引入压气机效率、压气机进口流量、透平效率和冷却空气流量4个独立参数的不确定分布,获得各影响参数不确定性相互耦合及独立情况下,燃机总体性能及部件运行参数概率分布。 结果 相比于其他3个参数,透平效率的不确定性对燃机输出功率分布、效率和排温的影响更明显;压气机效率虽然对其他部件工作状态的影响范围更大,但当叠加其他不确定因素后,影响程度降低;整机各处的温度和输出功率更易受部件不确定性的影响。 结论 设计及运行中透平应是重点关注部件。在燃机使用中,监测温度及输出功率更能捕捉到部件性能的波动。

中图分类号:

卢文强, 陈岩, 付经伦, 刘海松, 孔祥玲. 基于蒙特卡罗法的燃气轮机总体性能不确定性分析[J]. 发电技术, 2025, 46(1): 126-134.

Wenqiang LU, Yan CHEN, Jinglun FU, Haisong LIU, Xiangling KONG. Uncertainty Analysis of Gas Turbine Overall Performance Based on Monte Carlo Method[J]. Power Generation Technology, 2025, 46(1): 126-134.

| 参数 | 厂家公开数据 | Gatecycle软件 | GTPC软件 | ||

|---|---|---|---|---|---|

计算 结果 | 误差 | 计算 结果 | 误差 | ||

| 进气损失/MPa | 0 | 0 | 0 | 0 | 0 |

| 出气损失/MPa | 0 | 0 | 0 | 0 | 0 |

| P0/MPa | 0.101 3 | 0.101 3 | 0 | 0.101 3 | 0 |

| T0/℃ | 15 | 15 | 0 | 15 | 0 |

| G0/(kg/s) | 83.150 | 83.15 | 0 | 83.159 | 0.011 |

| G1/(kg/s) | 83.150 | 83.15 | 0 | 83.159 | 0.011 |

| P1/MPa | 1.013 | 1.013 | 0 | 1.013 | 0.000 |

| T1/℃ | 15 | 15 | 0 | 15 | 0.000 |

| G2/(kg/s) | — | 67.220 | — | 81.902 | — |

| P2/MPa | 2.200 2 | 2.340 6 | 0.638 1 | 2.200 3 | 0.004 |

| T2/℃ | 476.480 | 486.720 | 2.149 | 476.490 | 0.002 |

| ηcomp/% | — | 85 | — | 84.559 | — |

| Gf /(kg/s) | 1.730 | 1.670 | -3.468 | 1.730 | 0 |

| Tf /℃ | — | 15 | — | 15 | — |

| G3/(kg/s) | — | 68.890 | — | 68.258 | — |

| P3/MPa | — | 2.211 9 | — | 2.199 5 | — |

| T3 /℃ | — | 1 365.000 | — | 1 360.53 | — |

| ηturb /% | — | 90.000 | — | 85.664 | — |

| G4/(kg/s) | 84.330 | 83.570 | -0.901 | 84.889 | 0.663 |

| P4/MPa | 0.047 31 | 0.049 65 | 0.049 46 | 0.047 31 | 0 |

| T4/℃ | 835.560 | 837.110 | 0.185 | 835.630 | 0.008 |

| Gbleed3/(kg/s) | — | 1.250 | — | 1.247 | — |

| Pbleed3/MPa | 0.584 7 | 0.6420 | 0.980 0 | 0.584 7 | 0 |

| Tbleed3 /℃ | 280.630 | 241.800 | 13.837 | 280.630 | 0 |

| n /(r/min) | 9 687 | 9 586 | 1.043 | 9 687 | 0 |

| 效率/% | 31.372 | 31.880 | 1.619 | 31.370 | -0.006 |

| 功率/MW | 41.120 | 40.170 | -2.310 | 41.067 | -0.129 |

表 1 计算得到的热力性能

Tab. 1 Calculated thermal performance

| 参数 | 厂家公开数据 | Gatecycle软件 | GTPC软件 | ||

|---|---|---|---|---|---|

计算 结果 | 误差 | 计算 结果 | 误差 | ||

| 进气损失/MPa | 0 | 0 | 0 | 0 | 0 |

| 出气损失/MPa | 0 | 0 | 0 | 0 | 0 |

| P0/MPa | 0.101 3 | 0.101 3 | 0 | 0.101 3 | 0 |

| T0/℃ | 15 | 15 | 0 | 15 | 0 |

| G0/(kg/s) | 83.150 | 83.15 | 0 | 83.159 | 0.011 |

| G1/(kg/s) | 83.150 | 83.15 | 0 | 83.159 | 0.011 |

| P1/MPa | 1.013 | 1.013 | 0 | 1.013 | 0.000 |

| T1/℃ | 15 | 15 | 0 | 15 | 0.000 |

| G2/(kg/s) | — | 67.220 | — | 81.902 | — |

| P2/MPa | 2.200 2 | 2.340 6 | 0.638 1 | 2.200 3 | 0.004 |

| T2/℃ | 476.480 | 486.720 | 2.149 | 476.490 | 0.002 |

| ηcomp/% | — | 85 | — | 84.559 | — |

| Gf /(kg/s) | 1.730 | 1.670 | -3.468 | 1.730 | 0 |

| Tf /℃ | — | 15 | — | 15 | — |

| G3/(kg/s) | — | 68.890 | — | 68.258 | — |

| P3/MPa | — | 2.211 9 | — | 2.199 5 | — |

| T3 /℃ | — | 1 365.000 | — | 1 360.53 | — |

| ηturb /% | — | 90.000 | — | 85.664 | — |

| G4/(kg/s) | 84.330 | 83.570 | -0.901 | 84.889 | 0.663 |

| P4/MPa | 0.047 31 | 0.049 65 | 0.049 46 | 0.047 31 | 0 |

| T4/℃ | 835.560 | 837.110 | 0.185 | 835.630 | 0.008 |

| Gbleed3/(kg/s) | — | 1.250 | — | 1.247 | — |

| Pbleed3/MPa | 0.584 7 | 0.6420 | 0.980 0 | 0.584 7 | 0 |

| Tbleed3 /℃ | 280.630 | 241.800 | 13.837 | 280.630 | 0 |

| n /(r/min) | 9 687 | 9 586 | 1.043 | 9 687 | 0 |

| 效率/% | 31.372 | 31.880 | 1.619 | 31.370 | -0.006 |

| 功率/MW | 41.120 | 40.170 | -2.310 | 41.067 | -0.129 |

| 变量参数 | 概率分布函数 | 样本点分布 | ||

|---|---|---|---|---|

| M | S | M | S | |

| 压气机入口空气质量/(kg/s) | 105.00 | 5.25 | 104.84 | 5.26 |

| 压气机效率/% | 86.41 | 0.50 | 86.41 | 0.50 |

| 高压透平效率/% | 90.00 | 0.52 | 90.00 | 0.52 |

| 冷气相对流量/% | 19.15 | 0.25 | 19.15 | 0.25 |

表2 不确定参数分布

Tab. 2 Distribution of uncertainty parameters

| 变量参数 | 概率分布函数 | 样本点分布 | ||

|---|---|---|---|---|

| M | S | M | S | |

| 压气机入口空气质量/(kg/s) | 105.00 | 5.25 | 104.84 | 5.26 |

| 压气机效率/% | 86.41 | 0.50 | 86.41 | 0.50 |

| 高压透平效率/% | 90.00 | 0.52 | 90.00 | 0.52 |

| 冷气相对流量/% | 19.15 | 0.25 | 19.15 | 0.25 |

| 变量参数 | Case 1 | Case 2 | Case 3 | Case 4 | ||||

|---|---|---|---|---|---|---|---|---|

| M | S | M | S | M | S | M | S | |

| 压气机入口空气质量/(kg/s) | 104.84 | 0 | 104.84 | 0 | 104.84 | 5.26 | 104.84 | 5.26 |

| 压气机效率/% | 86.41 | 0.1、0.5、1.0、2.1 | 86.41 | 0 | 86.41 | 0.1、0.5、1.0、2.1 | 86.41 | 0.50 |

| 高压透平效率/% | 90.00 | 0 | 90.00 | 0.1、0.5、1.0、2.1 | 90.00 | 0.52 | 90.00 | 0.1、0.5、1.0、2.1 |

| 冷气相对流量/% | 19.15 | 0 | 19.15 | 0 | 19.15 | 0.25 | 19.15 | 0.25 |

表 3 各样本点不确定性参数概率分布

Tab. 3 Probability distributions of uncertainty parameters offor each sample point

| 变量参数 | Case 1 | Case 2 | Case 3 | Case 4 | ||||

|---|---|---|---|---|---|---|---|---|

| M | S | M | S | M | S | M | S | |

| 压气机入口空气质量/(kg/s) | 104.84 | 0 | 104.84 | 0 | 104.84 | 5.26 | 104.84 | 5.26 |

| 压气机效率/% | 86.41 | 0.1、0.5、1.0、2.1 | 86.41 | 0 | 86.41 | 0.1、0.5、1.0、2.1 | 86.41 | 0.50 |

| 高压透平效率/% | 90.00 | 0 | 90.00 | 0.1、0.5、1.0、2.1 | 90.00 | 0.52 | 90.00 | 0.1、0.5、1.0、2.1 |

| 冷气相对流量/% | 19.15 | 0 | 19.15 | 0 | 19.15 | 0.25 | 19.15 | 0.25 |

| 对比方案 | 不确定参数 | 分析内容 |

|---|---|---|

| Case 1 | 压气机效率 | 单参数及多因素耦合情况下,压气机效率不同概率分布程度的影响 |

| Case 3 | 压气机入口空气质量、压气机效率、透平效率、冷气相对流量 |

表 4 压气机效率不确定性对比方案

Tab. 4 Compressor efficiency uncertainty comparison

| 对比方案 | 不确定参数 | 分析内容 |

|---|---|---|

| Case 1 | 压气机效率 | 单参数及多因素耦合情况下,压气机效率不同概率分布程度的影响 |

| Case 3 | 压气机入口空气质量、压气机效率、透平效率、冷气相对流量 |

| 参数 | 数据类型 | 数值 | ||||

|---|---|---|---|---|---|---|

| 无偏差 | S=0.1 | S=0.5 | S=1.0 | S=2.0 | ||

| 压气机效率 | S/S0.1 | 1.000 | 5.141 | 10.137 | 15.555 | 19.427 |

| 燃油质量流量 | M/(kg/s) | 2.043 | 2.043 | 2.043 | 2.043 | 2.043 |

| S/S0.1 | 1.000 | 4.909 | 9.636 | 14.818 | 18.455 | |

| 排气温度 | M/℃ | 520.990 | 521.050 | 521.050 | 521.050 | 521.070 |

| S/S0.1 | 1.000 | 5.108 | 10.062 | 15.480 | 19.714 | |

| 压气机出口压力 | M/MPa | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 |

| S/S0.1 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| 压气机出口温度 | M/℃ | 472.500 | 472.500 | 472.500 | 472.500 | 472.500 |

| S/S0.1 | 1.000 | 5.143 | 10.138 | 15.593 | 19.502 | |

| 高压透平出口压力 | M/MPa | 0.555 2 | 0.555 2 | 0.555 2 | 0.555 1 | 0.555 0 |

| S/S0.1 | 1.000 | 5.157 | 10.176 | 15.627 | 19.520 | |

| 高压透平出口温度 | M/℃ | 849.830 | 849.810 | 849.850 | 849.730 | 849.660 |

| S/S0.1 | 1.000 | 5.142 | 10.136 | 15.595 | 19.510 | |

表 5 压气机效率不确定性下燃气轮机性能参数的概率分布

Tab. 5 Probability distribution of gas turbine performance parameters under compressor efficiency uncertainty

| 参数 | 数据类型 | 数值 | ||||

|---|---|---|---|---|---|---|

| 无偏差 | S=0.1 | S=0.5 | S=1.0 | S=2.0 | ||

| 压气机效率 | S/S0.1 | 1.000 | 5.141 | 10.137 | 15.555 | 19.427 |

| 燃油质量流量 | M/(kg/s) | 2.043 | 2.043 | 2.043 | 2.043 | 2.043 |

| S/S0.1 | 1.000 | 4.909 | 9.636 | 14.818 | 18.455 | |

| 排气温度 | M/℃ | 520.990 | 521.050 | 521.050 | 521.050 | 521.070 |

| S/S0.1 | 1.000 | 5.108 | 10.062 | 15.480 | 19.714 | |

| 压气机出口压力 | M/MPa | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 |

| S/S0.1 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| 压气机出口温度 | M/℃ | 472.500 | 472.500 | 472.500 | 472.500 | 472.500 |

| S/S0.1 | 1.000 | 5.143 | 10.138 | 15.593 | 19.502 | |

| 高压透平出口压力 | M/MPa | 0.555 2 | 0.555 2 | 0.555 2 | 0.555 1 | 0.555 0 |

| S/S0.1 | 1.000 | 5.157 | 10.176 | 15.627 | 19.520 | |

| 高压透平出口温度 | M/℃ | 849.830 | 849.810 | 849.850 | 849.730 | 849.660 |

| S/S0.1 | 1.000 | 5.142 | 10.136 | 15.595 | 19.510 | |

| 参数 | 数据类型 | 数值 | ||||

|---|---|---|---|---|---|---|

| 无偏差 | S=0.1 | S=0.5 | S=1.0 | S=2.0 | ||

| 压气机效率 | S/S0.1 | 1.000 | 4.867 | 9.814 | 14.758 | 20.168 |

| 燃油质量流量 | M/(kg/s) | 2.043 | 2.043 | 2.043 | 2.038 | 2.037 |

| S/S0.1 | 1.000 | 1.007 | 1.004 | 0.999 | 1.017 | |

| 排气温度 | M/℃ | 521.060 | 521.070 | 521.040 | 521.060 | 520.620 |

| S/S0.1 | 1.000 | 0.981 | 0.995 | 0.974 | 0.992 | |

| 压气机出口压力 | M/MPa | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

| 压气机出口温度 | M/℃ | 472.560 | 472.540 | 472.600 | 472.650 | 472.780 |

| S/S0.1 | 1.000 | 4.860 | 9.915 | 14.850 | 20.172 | |

| 高压透平出口压力 | M/MPa | 0.555 1 | 0.555 1 | 0.555 1 | 0.555 1 | 0.555 5 |

| S/S0.1 | 1.000 | 1.412 | 2.182 | 3.091 | 4.013 | |

| 高压透平出口温度 | M/℃ | 849.830 | 849.820 | 849.770 | 849.710 | 849.600 |

| S/S0.1 | 1.000 | 1.363 | 1.944 | 2.809 | 3.550 | |

表 6 压气机效率与其他参数不确定性耦合下燃气轮机性能参数的概率分布

Tab. 6 Probability distribution of gas turbine performance parameters under the coupling of compressor efficiency and other parameter uncertainties

| 参数 | 数据类型 | 数值 | ||||

|---|---|---|---|---|---|---|

| 无偏差 | S=0.1 | S=0.5 | S=1.0 | S=2.0 | ||

| 压气机效率 | S/S0.1 | 1.000 | 4.867 | 9.814 | 14.758 | 20.168 |

| 燃油质量流量 | M/(kg/s) | 2.043 | 2.043 | 2.043 | 2.038 | 2.037 |

| S/S0.1 | 1.000 | 1.007 | 1.004 | 0.999 | 1.017 | |

| 排气温度 | M/℃ | 521.060 | 521.070 | 521.040 | 521.060 | 520.620 |

| S/S0.1 | 1.000 | 0.981 | 0.995 | 0.974 | 0.992 | |

| 压气机出口压力 | M/MPa | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

| 压气机出口温度 | M/℃ | 472.560 | 472.540 | 472.600 | 472.650 | 472.780 |

| S/S0.1 | 1.000 | 4.860 | 9.915 | 14.850 | 20.172 | |

| 高压透平出口压力 | M/MPa | 0.555 1 | 0.555 1 | 0.555 1 | 0.555 1 | 0.555 5 |

| S/S0.1 | 1.000 | 1.412 | 2.182 | 3.091 | 4.013 | |

| 高压透平出口温度 | M/℃ | 849.830 | 849.820 | 849.770 | 849.710 | 849.600 |

| S/S0.1 | 1.000 | 1.363 | 1.944 | 2.809 | 3.550 | |

| 对比方案 | 不确定参数 | 分析内容 |

|---|---|---|

| Case 2 | 透平效率 | 单参数及多因素耦合情况下,透平效率不同概率分布程度的影响 |

| Case 4 | 压气机入口空气质量、压气机效率、透平效率、冷气相对流量 |

表 7 透平效率不确定性对比方案

Tab. 7 Turbine eefficiency uuncertainty comparison ccomparison sschemecases

| 对比方案 | 不确定参数 | 分析内容 |

|---|---|---|

| Case 2 | 透平效率 | 单参数及多因素耦合情况下,透平效率不同概率分布程度的影响 |

| Case 4 | 压气机入口空气质量、压气机效率、透平效率、冷气相对流量 |

| 参数 | 数据类型 | 数值 | ||||

|---|---|---|---|---|---|---|

| 无偏差 | S=0.1 | S=0.5 | S=1.0 | S=2.0 | ||

| 透平效率 | S/S0.1 | 1.000 | 5.190 | 10.619 | 15.204 | 20.889 |

| 燃油质量流量 | M/(kg/s) | 2.043 | 2.043 | 2.043 | 2.043 | 2.043 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

| 排气温度 | M/℃ | 520.990 | 521.050 | 520.990 | 520.990 | 520.930 |

| S/S0.1 | 1.000 | 5.190 | 10.618 | 15.207 | 20.893 | |

压气机出口 压力 | M/MPa | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

压气机出口 温度 | M/℃ | 472.500 | 472.500 | 472.500 | 472.500 | 472.500 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

高压透平排压 压力 | M/℃ | 0.555 3 | 0.555 2 | 0.555 2 | 0.555 2 | 0.555 1 |

| S/S0.1 | 1.000 | 5.184 | 10.612 | 15.184 | 20.867 | |

高压透平排气 温度 | M | 849.850 | 849.850 | 849.850 | 849.850 | 849.850 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

表8 透平效率不确定性下燃气轮机性能参数的概率分布

Tab. 8 Probability Probabilistic distributions of gas turbine performance parameters for single under turbine blade efficiency uncertainty

| 参数 | 数据类型 | 数值 | ||||

|---|---|---|---|---|---|---|

| 无偏差 | S=0.1 | S=0.5 | S=1.0 | S=2.0 | ||

| 透平效率 | S/S0.1 | 1.000 | 5.190 | 10.619 | 15.204 | 20.889 |

| 燃油质量流量 | M/(kg/s) | 2.043 | 2.043 | 2.043 | 2.043 | 2.043 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

| 排气温度 | M/℃ | 520.990 | 521.050 | 520.990 | 520.990 | 520.930 |

| S/S0.1 | 1.000 | 5.190 | 10.618 | 15.207 | 20.893 | |

压气机出口 压力 | M/MPa | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 | 2.237 1 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

压气机出口 温度 | M/℃ | 472.500 | 472.500 | 472.500 | 472.500 | 472.500 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

高压透平排压 压力 | M/℃ | 0.555 3 | 0.555 2 | 0.555 2 | 0.555 2 | 0.555 1 |

| S/S0.1 | 1.000 | 5.184 | 10.612 | 15.184 | 20.867 | |

高压透平排气 温度 | M | 849.850 | 849.850 | 849.850 | 849.850 | 849.850 |

| S/S0.1 | 0 | 0 | 0 | 0 | 0 | |

| 参数 | 数据类型 | 数值 | ||||

|---|---|---|---|---|---|---|

| 无偏差 | S=0.1 | S=0.5 | S=1.0 | S=2.0 | ||

| 透平效率 | S/S0.1 | 1.000 | 5.097 | 10.410 | 15.185 | 20.809 |

| 燃油质量流量 | M/(kg/s) | 2.043 | 2.043 | 2.043 | 2.038 | 2.043 |

| S/S0.1 | 1.000 | 1.001 | 1.000 | 0.998 | 0.999 | |

| 排气温度/℃ | M/℃ | 521.060 | 521.070 | 521.040 | 521.040 | 521.000 |

| S/S0.1 | 1.000 | 2.901 | 5.463 | 7.957 | 10.845 | |

| 压气机出口压力 | M/MPa | 22.371 | 22.371 | 22.371 | 22.371 | 22.371 |

| S/S0.1 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| 压气机出口温度 | M/℃ | 472.560 | 472.540 | 472.510 | 472.550 | 472.520 |

| S/S0.1 | 1.000 | 0.981 | 0.997 | 1.001 | 1.001 | |

| 高压透平排气压力 | M/MPa | 5.551 | 5.551 | 5.553 | 5.550 | 5.551 |

| S/S0.1 | 1.000 | 1.407 | 2.142 | 2.915 | 3.887 | |

| 高压透平排气温度 | M/℃ | 842.820 | 849.820 | 849.870 | 849.810 | 849.850 |

| S/S0.1 | 1.000 | 1.072 | 1.072 | 1.070 | 1.038 | |

表 9 透平效率与其他参数不确定性耦合下燃气轮机性能参数的概率分布

Tab. 9 Probability distribution of gas turbine performance parameters under the coupling of turbine efficiency and other parameter uncertainties

| 参数 | 数据类型 | 数值 | ||||

|---|---|---|---|---|---|---|

| 无偏差 | S=0.1 | S=0.5 | S=1.0 | S=2.0 | ||

| 透平效率 | S/S0.1 | 1.000 | 5.097 | 10.410 | 15.185 | 20.809 |

| 燃油质量流量 | M/(kg/s) | 2.043 | 2.043 | 2.043 | 2.038 | 2.043 |

| S/S0.1 | 1.000 | 1.001 | 1.000 | 0.998 | 0.999 | |

| 排气温度/℃ | M/℃ | 521.060 | 521.070 | 521.040 | 521.040 | 521.000 |

| S/S0.1 | 1.000 | 2.901 | 5.463 | 7.957 | 10.845 | |

| 压气机出口压力 | M/MPa | 22.371 | 22.371 | 22.371 | 22.371 | 22.371 |

| S/S0.1 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | |

| 压气机出口温度 | M/℃ | 472.560 | 472.540 | 472.510 | 472.550 | 472.520 |

| S/S0.1 | 1.000 | 0.981 | 0.997 | 1.001 | 1.001 | |

| 高压透平排气压力 | M/MPa | 5.551 | 5.551 | 5.553 | 5.550 | 5.551 |

| S/S0.1 | 1.000 | 1.407 | 2.142 | 2.915 | 3.887 | |

| 高压透平排气温度 | M/℃ | 842.820 | 849.820 | 849.870 | 849.810 | 849.850 |

| S/S0.1 | 1.000 | 1.072 | 1.072 | 1.070 | 1.038 | |

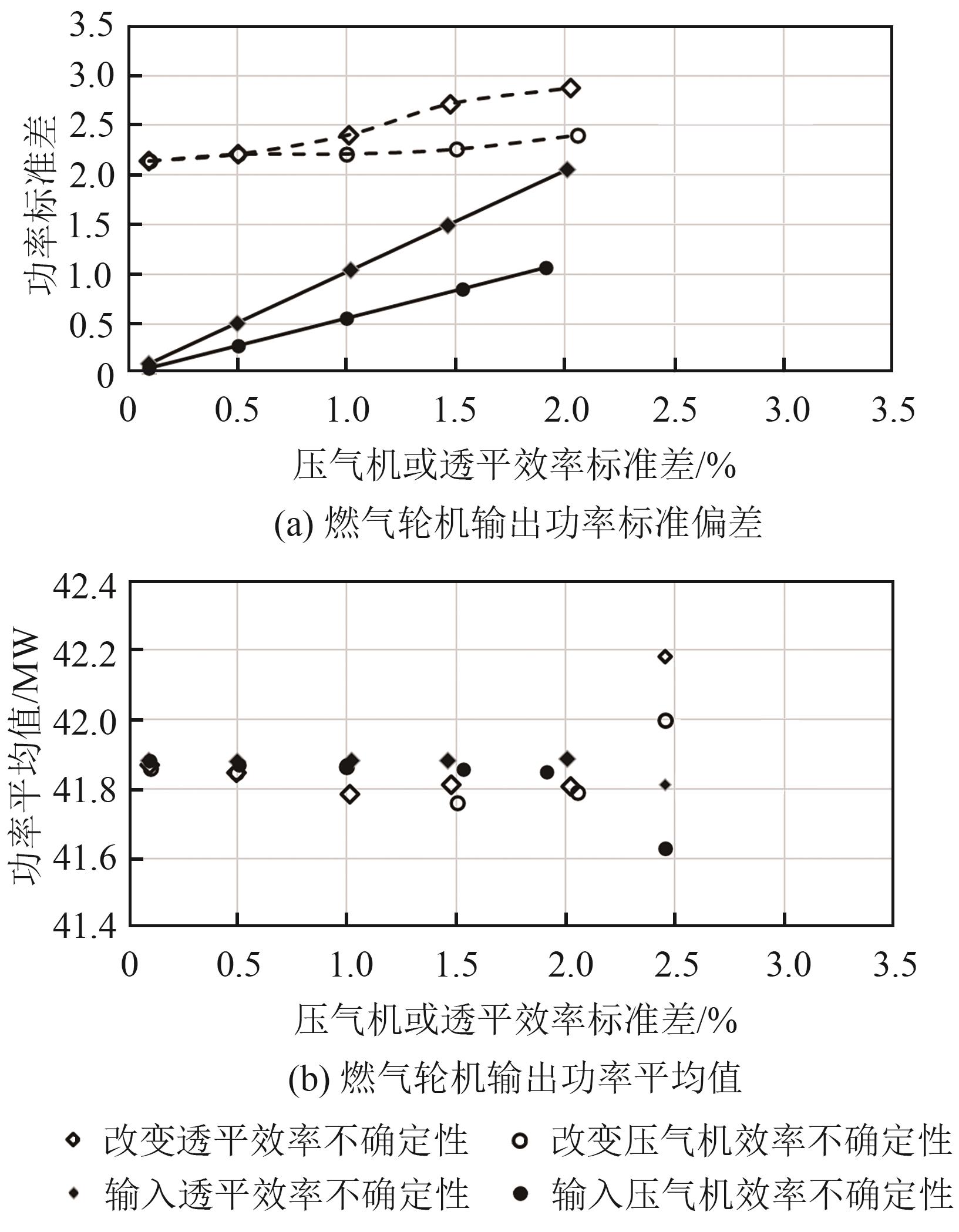

图 5 压气机或透平效率不同不确定性时燃气轮机输出功率的概率分布

Fig. 5 Probability distributions of gas turbine output power under different uncertainties of compressor or turbine efficiency

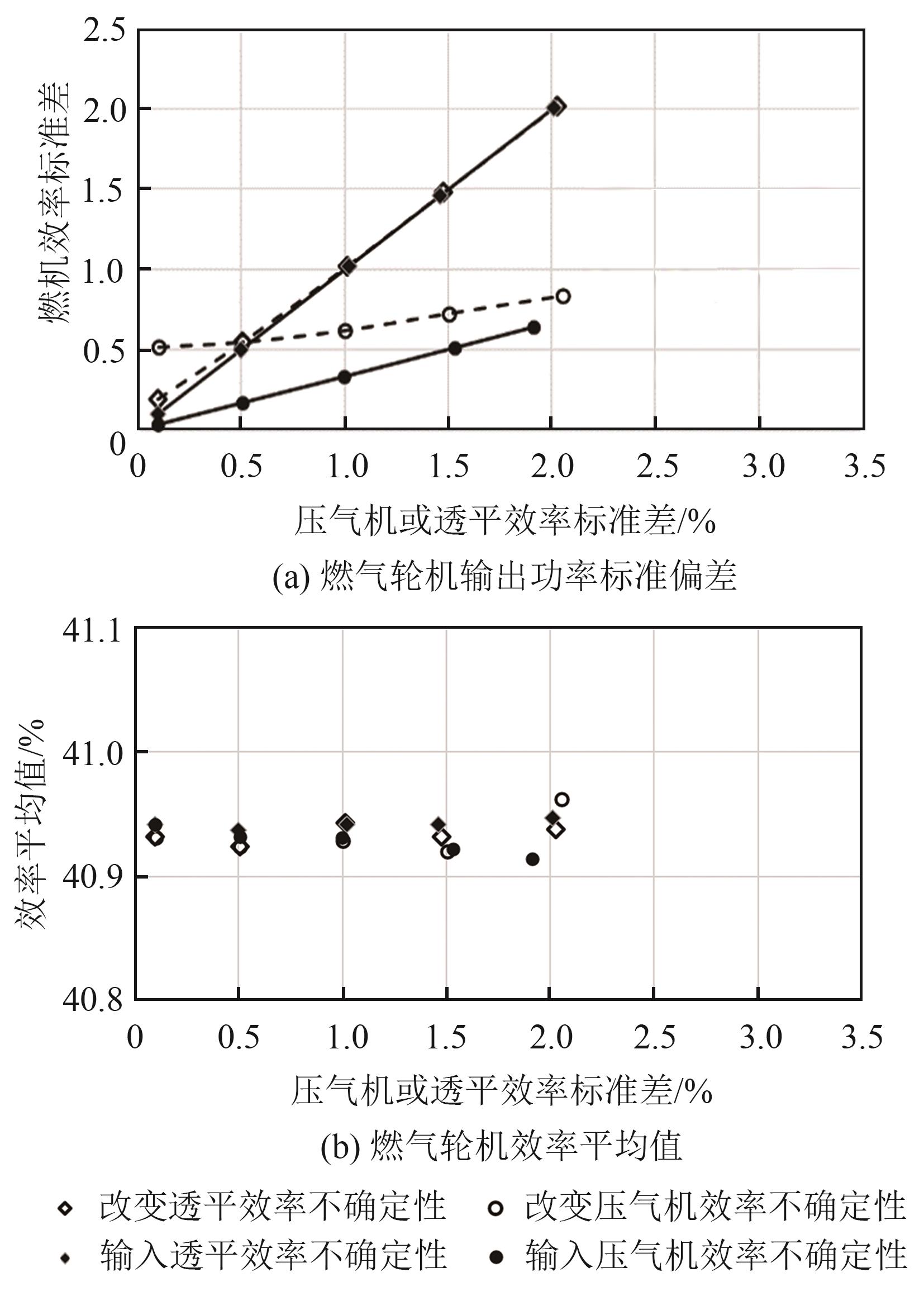

图 6 压气机/透平效率不同不确定性下燃气轮机效率的概率分布

Fig. 6 Probability distribution of gas turbine efficiency under different uncertainties of compressor or turbine efficiency

| 参数 | 原始 设计值 | 不确定性概率计算 | |

|---|---|---|---|

| M | S | ||

| 终端功率/MW | 41.876 | 41.847 | 2.201 |

| 燃机终端效率/% | 40.937 | 40.932 | 0.548 |

| 燃油质量流量/(kg/s) | 2.043 | 2.042 | 0.103 |

| 压气机出口压力/MPa | 2.237 1 | 2.237 1 | 0.000 0 |

| 压气机出口温度/℃ | 472.500 | 472.540 | 2.508 |

| 高压透平出口压力/MPa | 0.555 2 | 0.555 1 | 0.007 6 |

| 高压透平出口温度/℃ | 849.860 | 849.820 | 2.152 |

| 排气温度/℃ | 521.050 | 521.070 | 4.504 |

表 10 新设计燃气轮机参数的概率分布

Tab. 10 Probability distribution of newly designed gas turbine parameters

| 参数 | 原始 设计值 | 不确定性概率计算 | |

|---|---|---|---|

| M | S | ||

| 终端功率/MW | 41.876 | 41.847 | 2.201 |

| 燃机终端效率/% | 40.937 | 40.932 | 0.548 |

| 燃油质量流量/(kg/s) | 2.043 | 2.042 | 0.103 |

| 压气机出口压力/MPa | 2.237 1 | 2.237 1 | 0.000 0 |

| 压气机出口温度/℃ | 472.500 | 472.540 | 2.508 |

| 高压透平出口压力/MPa | 0.555 2 | 0.555 1 | 0.007 6 |

| 高压透平出口温度/℃ | 849.860 | 849.820 | 2.152 |

| 排气温度/℃ | 521.050 | 521.070 | 4.504 |

| 1 | 金云峰,刘超,邓高峰,等 .燃气轮机进气过滤系统维修周期经济性分析[J].发电技术,2022,43(1):119-125. |

| JIN Y F, LIU C, DENG G F,et al .Cost benefit analysis for maintenance strategy of gas turbine inlet filtration system[J].Power Generation Technology,2022,43(1):119-125. | |

| 2 | 邱彬,付经伦 .燃气轮机排气扩压器研究现状[J].发电技术,2021,42(4):437-446. |

| QIU B, FU J L .Research status of gas turbine exhaust diffuser[J].Power Generation Technology,2021,42(4):437-446. | |

| 3 | MONTOMOLI F, CARNEVALE M, D’AMMARO A,et al .Uncertainty quantification in computational fluid dynamics and aircraft engines[M].Berlin:Springer International Publishing,2015. doi:10.1007/978-3-319-14681-2_4 |

| 4 | BUNKER R S .The effects of manufacturing tolerances on gas turbine cooling[J].Journal of Turbomachinery,2009,131(4):041018. doi:10.1115/1.3072494 |

| 5 | SIDWELL V, DARMOFAL D .Probabilistic analysis of a turbine cooling air supply system:the effect on oxidation life[C]// ASME Turbo Expo 2003,Collocated with the 2003 International Joint Power Generation Conference.Atlanta,Georgia,USA:ASME,2003:1189-1198. doi:10.1115/gt2003-38119 |

| 6 | BATURIN O, POPOV G, NICOLALDE P .Identification of the mathematical model of a gas turbine engine taking into account the uncertainty of the intial data[C]//Proceeding of ASME Turbo Expo 2021.Newyork,USA:ASME,2021:76018. doi:10.1115/gtindia2021-76018 |

| 7 | ZHANG C Y, LU C, FEI C W,et al .Dynamic probabilistic design technique for multi-component system with multi-failure modes[J].Journal of Central South University,2018,25(11):2688-2700. doi:10.1007/s11771-018-3946-x |

| 8 | CLOUD D, STEARNS E .Probabilistic analysis of a turbofan secondary flow system[C]//Proceeding of ASME Turbo Expro 2004.Vienna,Austria:ASME,2004:53197. doi:10.1115/gt2004-53197 |

| 9 | STEARNS E,CLOUD,D, FILBURN T .Probabilistic thermal analysis of gas turbine internal hardware[C]//Proceeding of ASME Turbo Expro 2006.Barcelona,Spain:ASME,2006:90881. doi:10.1115/gt2006-90881 |

| 10 | COOKE A, CHILDS P, LONG C .Investigation into the effect of uncertainty in thermal properties on turbomachinery disc heat transfer using both a monte carlo simulation technique and a taylor series uncertainty propagation method[C]//Proceeding of ASME Turbo Expro 2007.Montreal,Canada:ASME,2007:27573. doi:10.1115/gt2007-27573 |

| 11 | BISCHOFF T, VOIGT M, CHEHAB E,et al .Probabilistic analysis of stationary gas turbine secondary air systems[C]//Proceeding of ASME Turbo Expro 2006.Barcelona,Spain:ASME,2006:90261. doi:10.1115/gt2006-90261 |

| 12 | CUNEO A, TRAVERSO A, SHAHPAR S .Comparative analysis of methodologies for uncertainty propagation and quantification[C]//Proceeding of ASME Turbo Expro 2017.Charlotte,North Carolina,USA:ASME,2017:63238. doi:10.1115/gt2017-63238 |

| 13 | YOUNGHANS J L, JOHNSON J E, CSONKA S J .A methodology to assess design uncertainty in selecting affordable gas turbine technology[C]//ASME 1994 International Gas Turbine and Aeroengine Congress and Exposition.Hague,Netherlands:ASME,1994:GT-419. doi:10.1115/94-gt-419 |

| 14 | KURZKE J .Some applications of the Monte Carlo method to gas turbine performance simulations[C]//Proceeding of ASME Turbo Expro 1997.Singapore:ASME,1997:97-GT-48. doi:10.1115/97-gt-048 |

| 15 | CHAO M A, LILLEY D S, MATHE P,et al .Calibration and uncertainty quantification of gas turbine performance models[C]//Proceeding of ASME Turbo Expro 2015.Montreal,Quebec,Canada:ASME,2015:42392. doi:10.1115/gt2015-42392 |

| 16 | 吴仲华 .气体热力学性质[M].北京:科学出版社,1957. |

| WU Z H .Thermodynamic Properties of Gas[M].Beijing:Science Press,1957. | |

| 17 | JOACHIM K .Some applications of the Monte Carlo method to gas turbine performance simulations[C]//Proceeding of ASME 1997.Singapore:ASME,1997:004T16A003. doi:10.1115/97-gt-048 |

| [1] | 管超骏, 雷正玲, 霍海波, 王芳, 姚国全, 刘涛. 基于强化学习的固体氧化物燃料电池输出电压自抗扰控制研究[J]. 发电技术, 2024, 45(6): 1163-1172. |

| [2] | 张超, 张海川, 付经伦, 童志庭, 朱俊强. 燃气轮机透平动叶横流带肋通道中气膜冷却研究进展[J]. 发电技术, 2024, 45(5): 781-792. |

| [3] | 任静, 李雪英. 燃气轮机透平叶片旋转内部冷却通道研究现状与发展趋势[J]. 发电技术, 2024, 45(5): 793-801. |

| [4] | 左秋儒, 栾勇, 熊逸辉, 饶宇. 燃气轮机透平叶片旋流冷却技术研究综述[J]. 发电技术, 2024, 45(5): 802-813. |

| [5] | 成明, 项阳阳, 杨光伟, 周强, 李军. H级燃气轮机掺氢发电技术应用现状及关键问题分析[J]. 发电技术, 2024, 45(5): 814-825. |

| [6] | 余文昶, 丁阳, 王旭阳, 陈永刚, 毕克, 刘志刚, 上官新刚, 黄道火, 肖峰, 李光, 王广, 柯汉章, 孙亚松, 王鑫. 重型燃气轮机透平一级动叶冷却结构优化与评估[J]. 发电技术, 2024, 45(5): 838-846. |

| [7] | 史玉恒, 刘润泽, 李士龙, 蒋东翔. SGT5-4000F燃气轮机改进升级措施分析[J]. 发电技术, 2024, 45(5): 847-855. |

| [8] | 赵明阳, 殷林林, 韦文涛, 陈云, 刘日晨, 李军. 高压涡轮动叶叶尖掉块对气动性能及振动的影响[J]. 发电技术, 2024, 45(5): 856-867. |

| [9] | 王铀, 张晓东, 郝佩, 韩旭, 邓路炜, 李国强, 魏福双, 吉祥. 适用于掺氢燃气轮机的新型环境/热障涂层[J]. 发电技术, 2024, 45(5): 868-877. |

| [10] | 冯福媛, 李童宇, 李博, 陈衡, 潘佩媛, 徐钢, 刘彤. 基于气化和热解的医疗垃圾-废旧轮胎联合资源化利用系统性能分析[J]. 发电技术, 2024, 45(4): 611-621. |

| [11] | 叶健强, 孙敦虎. 碳交易条件下基于鲁棒优化的电源规划研究[J]. 发电技术, 2024, 45(3): 566-574. |

| [12] | 付小标, 侯嘉琪, 李宝聚, 温亚坤, 赖晓文, 郭雷, 王志伟, 王尧, 张海锋, 李德鑫. 一种二模态天气分型方法及其在光伏功率概率预测的应用[J]. 发电技术, 2024, 45(2): 299-311. |

| [13] | 崔则阳, 孔祥玲, 付经伦, 施佳君. 一种基于图像的燃气轮机叶型参数测量方法[J]. 发电技术, 2024, 45(1): 106-112. |

| [14] | 贾晓强, 杨永标, 杜姣, 甘海庆, 杨楠. 气候变化条件下基于智能预测模型的虚拟电厂不确定性运行优化研究[J]. 发电技术, 2023, 44(6): 790-799. |

| [15] | 杨旸, 李耀强, 张金琦. 基于数值方法的燃气轮机贫预混旋流燃烧室单头部结构设计[J]. 发电技术, 2023, 44(5): 712-721. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||