发电技术 ›› 2024, Vol. 45 ›› Issue (5): 868-877.DOI: 10.12096/j.2096-4528.pgt.24120

• 燃气轮机发电技术 • 上一篇

王铀, 张晓东, 郝佩, 韩旭, 邓路炜, 李国强, 魏福双, 吉祥

收稿日期:2024-06-23

修回日期:2024-08-22

出版日期:2024-10-31

发布日期:2024-10-29

作者简介:基金资助:You WANG, Xiaodong ZHANG, Pei HAO, Xu HAN, Luwei DENG, Guoqiang LI, Fushuang WEI, Xiang JI

Received:2024-06-23

Revised:2024-08-22

Published:2024-10-31

Online:2024-10-29

Supported by:摘要:

目的 随着国家“双碳”战略(碳达峰、碳中和)的实施,现有的热防护涂层结构难以满足未来燃气轮机热防护涂层的要求。针对掺氢燃气轮机对热防护涂层的需求,提出了抗高温腐蚀的新型环境/热障涂层(environmental/thermal barrier coatings,E/TBC)结构的概念。 方法 从热防护涂层材料和涂层结构的角度,简要回顾及分析了热障涂层(thermal barrier coatings,TBC)、环境障涂层(environmental barrier coatings,EBC)、热障/环境障涂层(thermal/environmental barrier coatings,T/EBC)和热环境障涂层(thermal environmental barrier coatings,TEBC)的发展历程和研究现状,进而考察上述涂层结构与掺氢燃气轮机对热防护涂层需求之间的差距。 结果 将EBC的功能叠加到目前掺氢燃气轮机的热防护涂层上,从而在高温合金基体上形成一种抗高温腐蚀的新型E/TBC结构具有合理性。 结论 通过初步试验,证明E/TBC结构适用于掺氢燃气轮机抗高温水氧腐蚀的热防护涂层要求,指出应大力开展这种新型E/TBC热防护涂层的理论和应用研究。

中图分类号:

王铀, 张晓东, 郝佩, 韩旭, 邓路炜, 李国强, 魏福双, 吉祥. 适用于掺氢燃气轮机的新型环境/热障涂层[J]. 发电技术, 2024, 45(5): 868-877.

You WANG, Xiaodong ZHANG, Pei HAO, Xu HAN, Luwei DENG, Guoqiang LI, Fushuang WEI, Xiang JI. New Environmental/Thermal Barrier Coatings Suitable for Hydrogen Doped Gas Turbines[J]. Power Generation Technology, 2024, 45(5): 868-877.

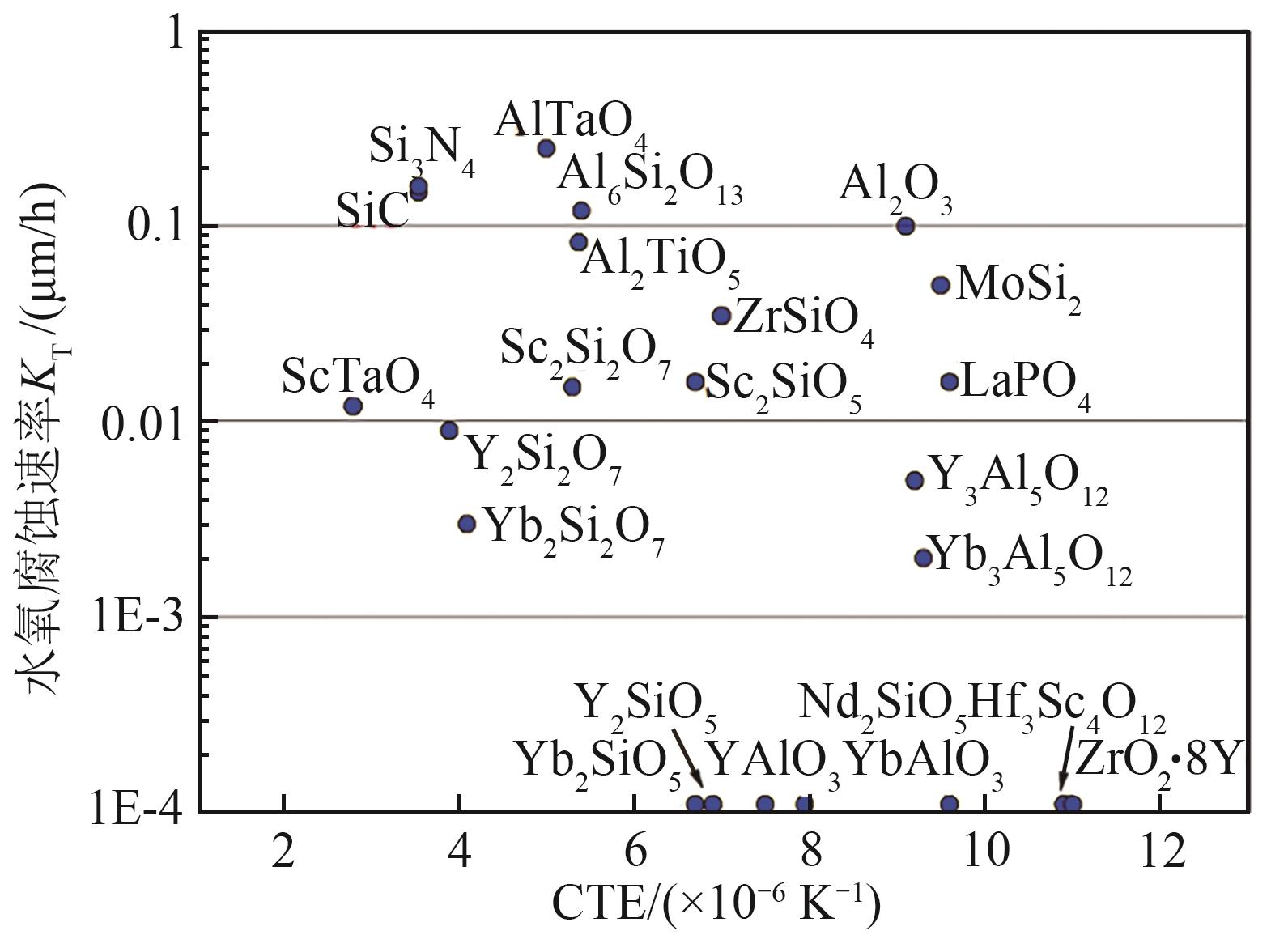

图5 几种陶瓷材料在1 450 ℃温度下水氧腐蚀速率与热膨胀系数关系示意图

Fig. 5 Schematic diagram of the relationship between water oxygen corrosion rate and thermal expansion coefficient of several ceramic materials at 1450 ℃

| 材料 | 热导率/[W/(m⋅K)] | 热膨胀系数/(×10-6⋅K-1) |

|---|---|---|

| Ni基高温合金[ | — | 14~16 |

| 8YSZ[ | 2.12(1 000 ℃) | 9~11 |

| Gd2Zr2O7[ | 1.91 | 7.91~9.18 |

| 5RE2Zr2O7[ | 0.7~1.5(300~1 300 ℃) | 10~11(500~1 400 ℃) |

| Yb2SiO5涂层[ | 0.68~1.13(200~1 400 ℃) | 6.9~7.6(200~1 400 ℃) |

| Yb2Si2O7涂层[ | 0.78~1.37(200~1 400 ℃) | 3.3~5.2(200~1 400 ℃) |

| (5RE0.2)2Si2O7[ | 1.146(1 100 ℃) | 1.96~3.95(300~1 300 ℃) |

表1 几种潜在E/TBC涂层材料的热物理性能

Tab. 1 Thermophysical properties of several potential E/TBC coating materials

| 材料 | 热导率/[W/(m⋅K)] | 热膨胀系数/(×10-6⋅K-1) |

|---|---|---|

| Ni基高温合金[ | — | 14~16 |

| 8YSZ[ | 2.12(1 000 ℃) | 9~11 |

| Gd2Zr2O7[ | 1.91 | 7.91~9.18 |

| 5RE2Zr2O7[ | 0.7~1.5(300~1 300 ℃) | 10~11(500~1 400 ℃) |

| Yb2SiO5涂层[ | 0.68~1.13(200~1 400 ℃) | 6.9~7.6(200~1 400 ℃) |

| Yb2Si2O7涂层[ | 0.78~1.37(200~1 400 ℃) | 3.3~5.2(200~1 400 ℃) |

| (5RE0.2)2Si2O7[ | 1.146(1 100 ℃) | 1.96~3.95(300~1 300 ℃) |

| 1 | 马勤勇,钱白云,董利江,等 .掺氢比例对氢混天然气燃气轮机运行特性影响的研究[J].热能动力工程,2022,37(9):41-49. |

| MA Q Y, QIAN B Y, DONG L J,et al .Research on the influence of hydrogen blending ratio on the operation characteristics of hydrogen blended fuel gas turbine[J].Journal of Engineering for Thermal Energy and Power,2022,37(9):41-49. | |

| 2 | 赵昊,楼国锋,刘少鹏,等 .掺氢对天然气燃烧室燃烧及排放特性影响[J].科学技术与工程,2024,24(1):223-229. |

| ZHAO H, LOU G F, LIU S P,et al .Effect of hydrogen mixing on the combustion and emission characteristics of natural gas combustion chamber[J].Science Technology and Engineering,2024,24(1):223-229. | |

| 3 | 杨盼 .铈锆酸镧基高温热障涂层的制备与性能研究[D].兰州:兰州大学,2022. |

| YANG P .Study on preparation and properties of La2(Zr0.75Ce0 .25 )2O7-based high-temperature thermal barrier coatings[D].Lanzhou:Lanzhou University,2022. | |

| 4 | PEREPEZKO J H .The hotter the engine,the better[J].Science,2009,326(5956):1068-1069. doi:10.1126/science.1179327 |

| 5 | JAMALI H, MOZAFARINIA R, SHOJA-RAZAVI R,et al .Comparison of hot corrosion behaviors of plasma-sprayed nanostructured and conventional YSZ thermal barrier coatings exposure to molten vanadium pentoxide and sodium sulfate[J].Journal of the European Ceramic Society,2014,34(2):485-492. doi:10.1016/j.jeurceramsoc.2013.08.006 |

| 6 | SAEEDI B, SABOUR A, KHODDAMI A M .Study of microstructure and thermal shock behavior of two types of thermal barrier coatings[J].Materials and Corrosion,2009,60(9):695-703. doi:10.1002/maco.200905111 |

| 7 | LEONI M, JONES R L, SCARDI P .Phase stability of scandia-yttria-stabilized zirconia TBCs[J].Surface and Coatings Technology,1998,108:107-113. doi:10.1016/s0257-8972(98)00617-3 |

| 8 | PADTURE N P, GELL M, JORDAN E H .Thermal barrier coatings for gas-turbine engine applications[J].Science,2002,296(5566):280-284. doi:10.1126/science.1068609 |

| 9 | WEI Z Y, MENG G H, CHEN L,et al .Progress in ceramic materials and structure design toward advanced thermal barrier coatings[J].Journal of Advanced Ceramics,2022,11(7):985-1068. doi:10.1007/s40145-022-0581-7 |

| 10 | BAI Y, HAN Z H, LI H Q,et al .High performance nanostructured ZrO2 based thermal barrier coatings deposited by high efficiency supersonic plasma spraying[J].Applied Surface Science,2011,257(16):7210-7216. doi:10.1016/j.apsusc.2011.03.092 |

| 11 | 魏秋利,郭洪波,宫声凯 .电子束物理气相沉积Nd2O3和Yb2O3共掺杂的YSZ热障涂层研究[J].航空学报,2007,28(S1):163-167. |

| WEI Q L, GUO H B, GONG S K,et al .Study on YSZ thermal barrier coatings co-doped with Nd2O3 and Yb2O3 by electron beam physical vapor deposition[J].Acta Aeronautica ET Astronautica Sinica,2007,28(S1):163-167. | |

| 12 | 王铀,刘勇,周飞飞,等 .热喷涂纳米结构热障涂层的高温长效服役性能研究进展[J].航空制造技术,2019,62(21):14-21. |

| WANG Y, LIU Y, ZHOU F F,et al .Research progress on high temperature and long service performance of thermal sprayed nanostructured thermal barrier coatings[J].Aeronautical Manufacturing Technology,2019,62(21):14-21. | |

| 13 | 周飞飞,刘敏,邓春明,等 .等离子喷涂用纳米结构T′ 相8YSZ球形喂料及应用展望[J].表面技术,2019,48(1):37-42. doi:10.3390/nano10010038 |

| ZHOU F F, LIU M, DENG C M,et al .Nanostructured T' phase 8YSZ spherical feedstocks for plasma spraying and application prospects[J].Surface Technology,2019,48(1):37-42. doi:10.3390/nano10010038 | |

| 14 | 王铀,王亮,刘赛月,等 .热喷涂纳米结构La2Zr2O7(LZ)/8YSZ双陶瓷热障涂层[J].中国表面工程,2016,29(1):16-24. |

| WANG Y, WANG L, LIU S Y,et al .Nanostructured La2Zr2O7(LZ)/8YSZ double ceramic layer thermal barrier coatings fabricated by thermal spraying[J].China Surface Engineering,2016,29(1):16-24. | |

| 15 | ZHOU F, WANG Y, CHEN W,et al .Fabrication and characterization of novel powder reconstitution derived nanostructured spherical La2(Zr0.75Ce0.25)2O7 feedstock for plasma spraying[J].Applied Surface Science,2018,459:468-476. doi:10.1016/j.apsusc.2018.08.040 |

| 16 | ROST C M, SACHET E, BORMAN T,et al .Entropy-stabilized oxides[J].Nature Communications,2015,6:8485. doi:10.1038/ncomms9485 |

| 17 | CHEN K, PEI X, TANG L,et al .A five-component entropy-stabilized fluorite oxide[J].Journal of the European Ceramic Society,2018,38(11):4161-4164. doi:10.1016/j.jeurceramsoc.2018.04.063 |

| 18 | 顾俊峰,邹冀,张帆,等 .高熵陶瓷材料研究进展[J].中国材料进展,2019,38(9):855-865. |

| GU J F, ZOU J, ZHANG F,et al .Recent progress in high-entropy ceramic materials[J].Materials China,2019,38(9):855-865. | |

| 19 | 颜邓伊,许文举,吉利,等 .高熵陶瓷材料的研究进展[J].材料保护,2023,56(8):35-49. |

| YAN D Y, XU W J, JI L,et al .Research progress of high-entropy ceramic materials[J].Materials Protection,2023,56(8):35-49. | |

| 20 | VAN ROODE M .Ceramic gas turbine development:need for a 10 year plan[J].Journal of Engineering for Gas Turbines and Power,2010,132(1):011301. doi:10.1115/1.3124669 |

| 21 | PADTURE N P .Advanced structural ceramics in aerospace propulsion[J].Nature Materials,2016,15:804-809. doi:10.1038/nmat4687 |

| 22 | NASIRI N AL, PATRA N, NI N,et al .Oxidation behaviour of SiC/SiC ceramic matrix composites in air[J].Journal of the European Ceramic Society,2016,36(14):3293-3302. doi:10.1016/j.jeurceramsoc.2016.05.051 |

| 23 | TEJERO-MARTIN D, BENNETT C, HUSSAIN T .A review on environmental barrier coatings:history,current state of the art and future developments[J].Journal of the European Ceramic Society,2021,41(3):1747-1768. doi:10.1016/j.jeurceramsoc.2020.10.057 |

| 24 | POERSCHKE D L, HASS D D, EUSTIS S,et al .Stability and CMAS resistance of ytterbium-silicate/hafnate EBCs/TBC for SiC composites[J].Journal of the American Ceramic Society,2015,98(1):278-286. doi:10.1111/jace.13262 |

| 25 | XU J, SARIN V K, DIXIT S,et al .Stability of interfaces in hybrid EBC/TBC coatings for Si-based ceramics in corrosive environments[J].International Journal of Refractory Metals and Hard Materials,2015,49:339-349. doi:10.1016/j.ijrmhm.2014.08.013 |

| 26 | TURCER L R, PADTURE N P .Towards multifunctional thermal environmental barrier coatings (TEBCs) based on rare-earth pyrosilicate solid-solution ceramics[J].Scripta Materialia,2018,154:111-117. doi:10.1016/j.scriptamat.2018.05.032 |

| 27 | MAIER N, RIXECKER G, NICKEL K G .Formation and stability of Gd,Y,Yb and Lu disilicates and their solid solutions[J].Journal of Solid State Chemistry,2006,179(6):1630-1635. doi:10.1016/j.jssc.2006.02.019 |

| 28 | 林俐,郑馨姚,周龙文 .基于燃氢燃气轮机的风光火储多能互补优化调度[J].电网技术,2022,46(8):3007-3022. |

| LIN L, ZHENG X Y, ZHOU L W .Wind-PV-thermal-storage multi-energy complementary optimal dispatching based on hydrogen gas turbine[J].Power System Technology,2022,46(8):3007-3022. | |

| 29 | 李祥晟,郭菡,郁鸿飞,等 .掺氢对燃气轮机燃烧室燃烧和排放性能的影响研究[J].西安交通大学学报,2022,56(6):9-16. |

| LI X S, GUO H, YU H F,et al .Study on combustion and emission performance of hydrogen fuel gas turbine combustor[J].Journal of Xi’an Jiaotong University,2022,56(6):9-16. | |

| 30 | 秦锋,秦亚迪,单彤文 .碳中和背景下氢燃料燃气轮机技术现状及发展前景[J].广东电力,2021,34(10):10-17. |

| QIN F, QIN Y D, SHAN T W .Technology status and development prospects of hydrogen fuel gas turbine under the background of carbon neutral[J].Guangdong Electric Power,2021,34(10):10-17. | |

| 31 | KANG N L, ZHU D, LIMA R S .Perspectives on environmental barrier coatings (EBCs) manufactured via air plasma spray (APS) on ceramic matrix composites (CMCs):a tutorial paper[J].Journal of Thermal Spray Technology,2021,30(1):40-58. doi:10.1007/s11666-021-01168-0 |

| 32 | WANG Y, LIU J .First-principles investigation on the corrosion resistance of rare earth disilicates in water vapor[J].Journal of the European Ceramic Society,2009,29(11):2163-2167. doi:10.1016/j.jeurceramsoc.2009.02.005 |

| 33 | 路明辉,冯志海,周延春 .硅基非氧化物陶瓷表面环境障涂层的研究进展[J].陶瓷学报,2015,36(2):107-118. |

| LU M H, FENG Z H, ZHOU Y C .Recent research progress on environmental barrier coatings for non-oxide ceramics[J].Journal of Ceramics,2015,36(2):107-118. | |

| 34 | 张博,李广荣,徐彤,等 .长寿命热障涂层的剥落机理及抗剥落结构设计[J].航空材料学报,2022,42(1):1-14. |

| ZHANG B, LI G R, XU T,et al .Failure mechanism and cracking-resistant design of thermal barrier coatings with long life span[J].Journal of Aeronautical Materials,2022,42(1):1-14. | |

| 35 | REN K, WANG Q, SHAO G,et al .Multicomponent high-entropy zirconates with comprehensive properties for advanced thermal barrier coating[J].Scripta Materialia,2020,178:382-386. doi:10.1016/j.scriptamat.2019.12.006 |

| 36 | ZHONG X, NIU Y, LI H,et al .Comparative study on high-temperature performance and thermal shock behavior of plasma-sprayed Yb2SiO5 and Yb2Si2O7 coatings[J].Surface and Coatings Technology,2018,349:636-646. doi:10.1016/j.surfcoat.2018.06.056 |

| 37 | WEI F, ZHANG D, GONG X,et al .A systematic analysis of the calcium-magnesium-aluminosilicate corrosion behavior of high-entropy (5Re0.2)2Si2O7 materials[J].Corrosion Science,2023,219:111221. doi:10.1016/j.corsci.2023.111221 |

| 38 | 王铀,张晓东,郝佩,等 .一种氢燃料燃气轮机用纳米结构热防护涂层及其制备方法:CN118326307A[P].2024-07-12. |

| WANG Y, ZHANG X D, HAO P,et al .A nanostructured thermal protection coating and preparation method for hydrogen fuel gas turbine[P].2024-07-12. |

| [1] | 张超, 张海川, 付经伦, 童志庭, 朱俊强. 燃气轮机透平动叶横流带肋通道中气膜冷却研究进展[J]. 发电技术, 2024, 45(5): 781-792. |

| [2] | 任静, 李雪英. 燃气轮机透平叶片旋转内部冷却通道研究现状与发展趋势[J]. 发电技术, 2024, 45(5): 793-801. |

| [3] | 左秋儒, 栾勇, 熊逸辉, 饶宇. 燃气轮机透平叶片旋流冷却技术研究综述[J]. 发电技术, 2024, 45(5): 802-813. |

| [4] | 成明, 项阳阳, 杨光伟, 周强, 李军. H级燃气轮机掺氢发电技术应用现状及关键问题分析[J]. 发电技术, 2024, 45(5): 814-825. |

| [5] | 余文昶, 丁阳, 王旭阳, 陈永刚, 毕克, 刘志刚, 上官新刚, 黄道火, 肖峰, 李光, 王广, 柯汉章, 孙亚松, 王鑫. 重型燃气轮机透平一级动叶冷却结构优化与评估[J]. 发电技术, 2024, 45(5): 838-846. |

| [6] | 史玉恒, 刘润泽, 李士龙, 蒋东翔. SGT5-4000F燃气轮机改进升级措施分析[J]. 发电技术, 2024, 45(5): 847-855. |

| [7] | 赵明阳, 殷林林, 韦文涛, 陈云, 刘日晨, 李军. 高压涡轮动叶叶尖掉块对气动性能及振动的影响[J]. 发电技术, 2024, 45(5): 856-867. |

| [8] | 冯福媛, 李童宇, 李博, 陈衡, 潘佩媛, 徐钢, 刘彤. 基于气化和热解的医疗垃圾-废旧轮胎联合资源化利用系统性能分析[J]. 发电技术, 2024, 45(4): 611-621. |

| [9] | 崔则阳, 孔祥玲, 付经伦, 施佳君. 一种基于图像的燃气轮机叶型参数测量方法[J]. 发电技术, 2024, 45(1): 106-112. |

| [10] | 杨旸, 李耀强, 张金琦. 基于数值方法的燃气轮机贫预混旋流燃烧室单头部结构设计[J]. 发电技术, 2023, 44(5): 712-721. |

| [11] | 杨旸, 郭德三, 李耀强, 张金琦. 燃气轮机贫预混多旋流组合燃烧室头部结构设计[J]. 发电技术, 2023, 44(2): 183-192. |

| [12] | 张弘毅, 曲立涛. 9F级燃机选择性催化还原脱硝数值模拟研究与应用[J]. 发电技术, 2023, 44(1): 78-84. |

| [13] | 金云峰, 刘超, 邓高峰, 关运龙, 郝建刚, 黄海舟, 蒋东翔. 燃气轮机进气过滤系统维修周期经济性分析[J]. 发电技术, 2022, 43(1): 119-125. |

| [14] | 白明亮, 张冬雪, 刘金福, 刘娇, 于达仁. 基于深度自编码器和支持向量数据描述的燃气轮机高温部件异常检测[J]. 发电技术, 2021, 42(4): 422-430. |

| [15] | 孔祥玲, 付经伦. 基于计算机视觉的三维重建技术在燃气轮机行业的应用及展望[J]. 发电技术, 2021, 42(4): 454-463. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||