发电技术 ›› 2024, Vol. 45 ›› Issue (4): 611-621.DOI: 10.12096/j.2096-4528.pgt.22122

冯福媛, 李童宇, 李博, 陈衡, 潘佩媛, 徐钢, 刘彤

收稿日期:2023-11-18

修回日期:2024-02-18

出版日期:2024-08-31

发布日期:2024-08-27

通讯作者:

陈衡

作者简介:基金资助:Fuyuan FENG, Tongyu LI, Bo LI, Heng CHEN, Peiyuan PAN, Gang XU, Tong LIU

Received:2023-11-18

Revised:2024-02-18

Published:2024-08-31

Online:2024-08-27

Contact:

Heng CHEN

Supported by:摘要:

目的 随着固体废物产生量的逐年增加,传统的处理方法难以满足日益严格的环保要求和资源循环利用的需求。为实现固体废物资源的高效利用,提出一种基于气化和热解的医疗垃圾-废旧轮胎联合资源化利用系统。 方法 该系统充分结合等离子气化技术以及热解技术的优势,将医疗垃圾等离子气化发电技术与轮胎热解技术进行耦合,将气化和热解过程得到的合成气共同作为燃气轮机的燃料加以利用,同时,燃气透平产生的高温烟气为轮胎热解提供热源,之后再通过余热锅炉回收烟气热量。在无害化处理医疗垃圾-废旧轮胎的同时,实现了能量的梯级利用。在固定给料速率的条件下,对所提出系统进行了能量分析和经济性分析。 结果 该系统能实现23.59 MW总能量的输出,总能量利用效率达到52.56%,远高于传统的垃圾发电效率。该系统具有良好的经济收益,在20年的生命周期内,可以实现相对净现值72 797.81万元,且动态投资回收周期仅为3.13年。 结论 研究成果为固体废物资源的高效协同处理提供了新的技术路径。

中图分类号:

冯福媛, 李童宇, 李博, 陈衡, 潘佩媛, 徐钢, 刘彤. 基于气化和热解的医疗垃圾-废旧轮胎联合资源化利用系统性能分析[J]. 发电技术, 2024, 45(4): 611-621.

Fuyuan FENG, Tongyu LI, Bo LI, Heng CHEN, Peiyuan PAN, Gang XU, Tong LIU. Performance Analysis of Combined Medical Waste-Waste Tire Resource Utilization System Based on Gasification and Pyrolysis[J]. Power Generation Technology, 2024, 45(4): 611-621.

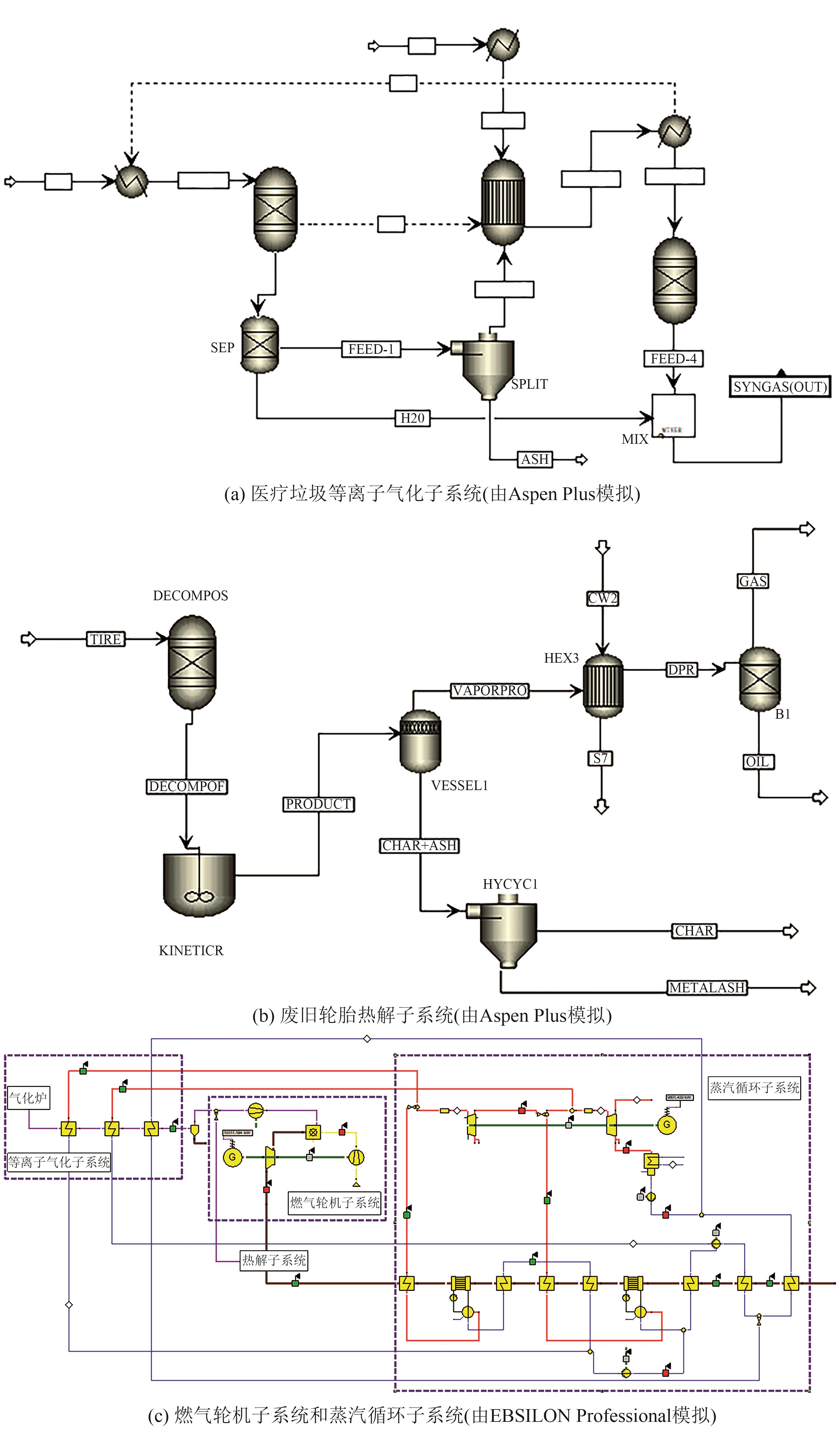

图2 基于气化和热解的医疗垃圾-废旧轮胎联合资源化利用系统仿真模型

Fig. 2 Simulation models for combined medical waste-waste tire resource utilization system based on gasification and pyrolysis

| 参数 | 数值 | |

|---|---|---|

| 工业分析 | 水分质量分数/% | 0.32 |

| 固定碳质量分数/% | 0.55 | |

| 挥发分质量分数/% | 99.13 | |

| 灰分质量分数/% | 0.00 | |

| 元素分析 | 碳质量分数/% | 81.55 |

| 氢质量分数/% | 12.13 | |

| 氧质量分数/% | 5.74 | |

| 氮质量分数/% | 0.15 | |

| 硫质量分数/% | 0.11 | |

| 低位发热量/(MJ⋅kg-1) | 42.49 | |

表1 典型医疗垃圾的物性参数

Tab. 1 Physical parameters of typical medical waste

| 参数 | 数值 | |

|---|---|---|

| 工业分析 | 水分质量分数/% | 0.32 |

| 固定碳质量分数/% | 0.55 | |

| 挥发分质量分数/% | 99.13 | |

| 灰分质量分数/% | 0.00 | |

| 元素分析 | 碳质量分数/% | 81.55 |

| 氢质量分数/% | 12.13 | |

| 氧质量分数/% | 5.74 | |

| 氮质量分数/% | 0.15 | |

| 硫质量分数/% | 0.11 | |

| 低位发热量/(MJ⋅kg-1) | 42.49 | |

| 项目 | 数值 |

|---|---|

| 医疗垃圾进料量/(kg⋅s-1) | 1.00 |

| 氧气进口流量/(kg⋅s-1) | 0.34 |

| 氧气进口温度/℃ | 25.00 |

| 合成气出口流量/(kg⋅s-1) | 1.34 |

| 合成气出口温度/℃ | 1 105.14 |

| 等离子体火炬热功率% | 85 |

| 等离子体火炬耗功/kW | 1 830 |

| 空分耗功/kW | 340 |

| 冷气效率/% | 82.04 |

表2 等离子气化炉的参数

Tab. 2 Parameters of plasma gasifier

| 项目 | 数值 |

|---|---|

| 医疗垃圾进料量/(kg⋅s-1) | 1.00 |

| 氧气进口流量/(kg⋅s-1) | 0.34 |

| 氧气进口温度/℃ | 25.00 |

| 合成气出口流量/(kg⋅s-1) | 1.34 |

| 合成气出口温度/℃ | 1 105.14 |

| 等离子体火炬热功率% | 85 |

| 等离子体火炬耗功/kW | 1 830 |

| 空分耗功/kW | 340 |

| 冷气效率/% | 82.04 |

| 参数 | 数值 | |

|---|---|---|

| 合成气组成成分 | H2摩尔分数/% | 24.29 |

| CO摩尔分数/% | 35.04 | |

| CH4摩尔分数/% | 20.08 | |

| H2O摩尔分数/% | 0.20 | |

| N2摩尔分数/% | 0.01 | |

| H2S摩尔分数/% | 0.05 | |

| HCN摩尔分数/% | 0.14 | |

| 低位发热量/(MJ⋅kg方正汇总行-1) | 30.40 | |

表3 等离子气化炉出口合成气的参数

Tab. 3 Parameters of syngas at the outlet of plasma gasifier

| 参数 | 数值 | |

|---|---|---|

| 合成气组成成分 | H2摩尔分数/% | 24.29 |

| CO摩尔分数/% | 35.04 | |

| CH4摩尔分数/% | 20.08 | |

| H2O摩尔分数/% | 0.20 | |

| N2摩尔分数/% | 0.01 | |

| H2S摩尔分数/% | 0.05 | |

| HCN摩尔分数/% | 0.14 | |

| 低位发热量/(MJ⋅kg方正汇总行-1) | 30.40 | |

| 参数 | 数值 | |

|---|---|---|

| 工业分析 | 水分质量分数/% | 1.50 |

| 固定碳质量分数/% | 30.00 | |

| 挥发分质量分数/% | 55.00 | |

| 灰分质量分数/% | 13.50 | |

| 元素分析 | 碳质量分数/% | 75.00 |

| 氢质量分数/% | 7.00 | |

| 氧质量分数/% | 2.70 | |

| 氮质量分数/% | 0.30 | |

| 低位发热量/(MJ⋅kg-1) | 34.38 | |

表4 废旧轮胎的物性参数

Tab. 4 Physical parameters of waste tire

| 参数 | 数值 | |

|---|---|---|

| 工业分析 | 水分质量分数/% | 1.50 |

| 固定碳质量分数/% | 30.00 | |

| 挥发分质量分数/% | 55.00 | |

| 灰分质量分数/% | 13.50 | |

| 元素分析 | 碳质量分数/% | 75.00 |

| 氢质量分数/% | 7.00 | |

| 氧质量分数/% | 2.70 | |

| 氮质量分数/% | 0.30 | |

| 低位发热量/(MJ⋅kg-1) | 34.38 | |

| 参数 | 数值 |

|---|---|

| 热解反应器的温度/℃ | 580.00 |

| 轮胎进料量/(kg⋅s-1) | 0.042 3 |

| 热解产物的冷却温度/℃ | 40.00 |

| 热解合成气的流量/(kg⋅s-1) | 0.002 2 |

| 热解油的流量/(kg⋅s-1) | 0.026 1 |

| 热解炭的流量/(kg⋅s-1) | 0.008 3 |

表5 轮胎热解子系统的参数

Tab. 5 Parameters of the tire pyrolysis subsystem

| 参数 | 数值 |

|---|---|

| 热解反应器的温度/℃ | 580.00 |

| 轮胎进料量/(kg⋅s-1) | 0.042 3 |

| 热解产物的冷却温度/℃ | 40.00 |

| 热解合成气的流量/(kg⋅s-1) | 0.002 2 |

| 热解油的流量/(kg⋅s-1) | 0.026 1 |

| 热解炭的流量/(kg⋅s-1) | 0.008 3 |

| 参数 | 数值 |

|---|---|

| 空气进气温度/℃ | 25.00 |

| 空气进气压力/MPa | 0.10 |

| 空气进气流量/(kg⋅s-1) | 40.74 |

| 空气压缩机的机械效率/% | 99.00 |

| 燃烧室进口压力/MPa | 1.69 |

| 燃烧室出口温度/℃ | 1 249.51 |

| 燃气轮机机械效率/% | 99.00 |

| 燃气轮机出口温度/℃ | 591.70 |

表6 燃气轮机子系统的参数

Tab. 6 Parameters of gas turbine subsystem

| 参数 | 数值 |

|---|---|

| 空气进气温度/℃ | 25.00 |

| 空气进气压力/MPa | 0.10 |

| 空气进气流量/(kg⋅s-1) | 40.74 |

| 空气压缩机的机械效率/% | 99.00 |

| 燃烧室进口压力/MPa | 1.69 |

| 燃烧室出口温度/℃ | 1 249.51 |

| 燃气轮机机械效率/% | 99.00 |

| 燃气轮机出口温度/℃ | 591.70 |

| 参数 | 数值 |

|---|---|

| 高(中)压蒸汽温度/℃ | 543.0(258.0) |

| 高(中)压蒸汽压力/MPa | 12.40(1.03) |

| 高(中)压汽轮机等熵效率/% | 90.0(90.0) |

| 高(中)压汽轮机机械效率/% | 99.0(99.0) |

| 凝汽器压力/MPa | 0.004 8 |

表7 蒸汽循环子系统的参数

Tab. 7 Parameters of steam cycle subsystem

| 参数 | 数值 |

|---|---|

| 高(中)压蒸汽温度/℃ | 543.0(258.0) |

| 高(中)压蒸汽压力/MPa | 12.40(1.03) |

| 高(中)压汽轮机等熵效率/% | 90.0(90.0) |

| 高(中)压汽轮机机械效率/% | 99.0(99.0) |

| 凝汽器压力/MPa | 0.004 8 |

| 参数 | 数值 |

|---|---|

| 医疗垃圾进料量/(kg⋅s-1) | 1.00 |

| 气化剂(氧气)流量/(kg⋅s-1) | 0.34 |

| 轮胎进料量/(kg⋅s-1) | 0.04 |

| 热解子系统输出的能量/MW | 1.42 |

| 系统输出的电能/MW | 24.32 |

| 等离子体火炬耗功/MW | 1.83 |

| 空分装置耗功/MW | 0.32 |

| 系统输出的净总能量/MW | 23.59 |

| 系统的总能量输出效率/% | 52.56 |

表8 集成系统的能量分析

Tab. 8 Energy analysis of integrated system

| 参数 | 数值 |

|---|---|

| 医疗垃圾进料量/(kg⋅s-1) | 1.00 |

| 气化剂(氧气)流量/(kg⋅s-1) | 0.34 |

| 轮胎进料量/(kg⋅s-1) | 0.04 |

| 热解子系统输出的能量/MW | 1.42 |

| 系统输出的电能/MW | 24.32 |

| 等离子体火炬耗功/MW | 1.83 |

| 空分装置耗功/MW | 0.32 |

| 系统输出的净总能量/MW | 23.59 |

| 系统的总能量输出效率/% | 52.56 |

| 参数 | 数值 |

|---|---|

| 生命周期/a | 20 |

| 建设周期/a | 1 |

| 年运行时间/h | 7 000 |

| 医疗垃圾处理补贴/(元/t) | 3 080.03 |

| 玻璃样渣的价格/(元/t) | 357.10 |

| 热解油的价格/(元/t) | 776.88 |

| 热解炭的价格/(元/t) | 471.44 |

| 上网电价/[元/(kW⋅h)] | 0.65 |

| 运行成本/万元 | 10%总投资 |

| 贴现率/% | 10 |

| 人民币对美元汇率 | 6.64 |

表9 经济性分析相关参数

Tab. 9 Parameters related to economic analysis

| 参数 | 数值 |

|---|---|

| 生命周期/a | 20 |

| 建设周期/a | 1 |

| 年运行时间/h | 7 000 |

| 医疗垃圾处理补贴/(元/t) | 3 080.03 |

| 玻璃样渣的价格/(元/t) | 357.10 |

| 热解油的价格/(元/t) | 776.88 |

| 热解炭的价格/(元/t) | 471.44 |

| 上网电价/[元/(kW⋅h)] | 0.65 |

| 运行成本/万元 | 10%总投资 |

| 贴现率/% | 10 |

| 人民币对美元汇率 | 6.64 |

| 部件 | 成本计算公式 | 变量注释 | 来源文献 |

|---|---|---|---|

| 气化炉/热解反应器 | m为物料的质量流量 | [ | |

| 换热器 | [ | ||

| 压缩机 | W为压缩机耗功 | [ | |

| 燃烧室 | [ | ||

| 燃气轮机 | [ | ||

| 余热锅炉 | [ | ||

| 蒸汽轮机 | W为发电功率 | [ | |

| 凝汽器 | [ | ||

| 发电机 | W为发电功率 | [ | |

| 泵 | [ |

表10 基于经验公式法的成本估算

Tab. 10 Cost estimation based on empirical formula

| 部件 | 成本计算公式 | 变量注释 | 来源文献 |

|---|---|---|---|

| 气化炉/热解反应器 | m为物料的质量流量 | [ | |

| 换热器 | [ | ||

| 压缩机 | W为压缩机耗功 | [ | |

| 燃烧室 | [ | ||

| 燃气轮机 | [ | ||

| 余热锅炉 | [ | ||

| 蒸汽轮机 | W为发电功率 | [ | |

| 凝汽器 | [ | ||

| 发电机 | W为发电功率 | [ | |

| 泵 | [ |

| 部件 | 参考成本/(×103美元) | 参考规模 | 规模因子 | 来源文献 |

|---|---|---|---|---|

| 等离子体火炬 | 1 500.00 | 5.75 MW | 0.91 | [ |

| 1#分离器 | 33 650.00 | 4 232.70 kmol/h | 0.65 | [ |

| 空分装置 | 45 700.00 | 76.68 t/h | 0.50 | [ |

表11 基于规模因子法的成本估算

Tab. 11 Cost estimation based on scaled factor approach

| 部件 | 参考成本/(×103美元) | 参考规模 | 规模因子 | 来源文献 |

|---|---|---|---|---|

| 等离子体火炬 | 1 500.00 | 5.75 MW | 0.91 | [ |

| 1#分离器 | 33 650.00 | 4 232.70 kmol/h | 0.65 | [ |

| 空分装置 | 45 700.00 | 76.68 t/h | 0.50 | [ |

| 组成 | 投资成本/万元 | |

|---|---|---|

| 等离子气化子系统 | 气化炉 | 4 720.39 |

| 等离子体火炬 | 350.63 | |

| 1#、2#、3#换热器 | 97.98 | |

| 1#分离器 | 3 603.28 | |

| 空分装置 | 3 833.84 | |

| 合计 | 12 606.12 | |

| 热解子系统 | 热解反应器 | 515.72 |

| 4#换热器 | 3.02 | |

| 合计 | 518.74 | |

| 燃气轮机子系统 | 合成气压缩机 | 8.92 |

| 空气压缩机 | 710.38 | |

| 燃烧室 | 53.54 | |

| 燃气轮机 | 6 505.89 | |

| 发电机 | 373.64 | |

| 合计 | 7 652.37 | |

| 蒸汽循环子系统 | 余热锅炉 | 3 534.67 |

| 蒸汽轮机 | 3 070.76 | |

| 凝汽器 | 116.36 | |

| 泵 | 45.42 | |

| 发电机 | 246.63 | |

| 合计 | 7 013.84 | |

| 总计 | 27 791.07 | |

表12 新系统中各组成部分的投资成本

Tab. 12 Investment cost of each component in the novel system

| 组成 | 投资成本/万元 | |

|---|---|---|

| 等离子气化子系统 | 气化炉 | 4 720.39 |

| 等离子体火炬 | 350.63 | |

| 1#、2#、3#换热器 | 97.98 | |

| 1#分离器 | 3 603.28 | |

| 空分装置 | 3 833.84 | |

| 合计 | 12 606.12 | |

| 热解子系统 | 热解反应器 | 515.72 |

| 4#换热器 | 3.02 | |

| 合计 | 518.74 | |

| 燃气轮机子系统 | 合成气压缩机 | 8.92 |

| 空气压缩机 | 710.38 | |

| 燃烧室 | 53.54 | |

| 燃气轮机 | 6 505.89 | |

| 发电机 | 373.64 | |

| 合计 | 7 652.37 | |

| 蒸汽循环子系统 | 余热锅炉 | 3 534.67 |

| 蒸汽轮机 | 3 070.76 | |

| 凝汽器 | 116.36 | |

| 泵 | 45.42 | |

| 发电机 | 246.63 | |

| 合计 | 7 013.84 | |

| 总计 | 27 791.07 | |

| 参数 | 数值 |

|---|---|

| 年净发电量/(MW⋅h) | 155 152.26 |

| 年炉渣产量/t | 4 536.00 |

| 年净发电收入/万元 | 9 942.57 |

| 年垃圾处理补贴/万元 | 7 761.68 |

| 年炉渣销售收入/万元 | 161.98 |

| 年热解油销售收入/万元 | 51.16 |

| 年热解炭销售收入/万元 | 9.86 |

| 年总收入/万元 | 17 927.25 |

| 总投资成本/万元 | 27 791.07 |

| 年运营成本/万元 | 2 779.10 |

| 动态回收周期/年 | 3.13 |

| 净现值/万元 | 72 797.81 |

表13 新系统的经济性分析结果

Tab. 13 Economic analysis results of the novel system

| 参数 | 数值 |

|---|---|

| 年净发电量/(MW⋅h) | 155 152.26 |

| 年炉渣产量/t | 4 536.00 |

| 年净发电收入/万元 | 9 942.57 |

| 年垃圾处理补贴/万元 | 7 761.68 |

| 年炉渣销售收入/万元 | 161.98 |

| 年热解油销售收入/万元 | 51.16 |

| 年热解炭销售收入/万元 | 9.86 |

| 年总收入/万元 | 17 927.25 |

| 总投资成本/万元 | 27 791.07 |

| 年运营成本/万元 | 2 779.10 |

| 动态回收周期/年 | 3.13 |

| 净现值/万元 | 72 797.81 |

| 1 | 陈刚,于晓东,岳佳妮,等 .医疗废物处理处置污染控制标准解读[J].环境保护科学,2021,47(3):1-6. doi:10.16803/j.cnki.issn.1004-6216.2021.03.001 |

| CHEN G, YU X D, YUE J N,et al .Interpretation of standard for pollution control on medical waste treatment and disposal[J].Environmental Protection Science,2021,47(3):1-6. doi:10.16803/j.cnki.issn.1004-6216.2021.03.001 | |

| 2 | WANG Z, ZHU M, HE T,et al .Chemical looping reforming of toluene as a biomass tar model compound over two types of oxygen carriers:2CuO-2NiO/Al2O3 and CaFe2O4 [J].Fuel,2018,222:375-384. doi:10.1016/j.fuel.2018.02.164 |

| 3 | 葛金林,肖海平,闫大海 .生物质与生活垃圾共气化过程重金属的迁移转化规律[J].发电技术,2020,41(5):552-560. doi:10.12096/j.2096-4528.pgt.20060 |

| GE J L, XIAO H P, YAN D H .Migration and transformation of heavy metals in the co-gasification of biomass and municipal waste[J].Power Generation Technology,2020,41(5):552-560. doi:10.12096/j.2096-4528.pgt.20060 | |

| 4 | MARY JOSEPH A, SNELLINGS R, NIELSEN P,et al .Pre-treatment and utilisation of municipal solid waste incineration bottom ashes towards a circular economy[J].Construction and Building Materials,2020,260:120485. doi:10.1016/j.conbuildmat.2020.120485 |

| 5 | PEI S L, CHEN T L, PAN S Y,et al .Addressing environmental sustainability of plasma vitrification technology for stabilization of municipal solid waste incineration fly ash[J].Journal of Hazardous Materials,2020,398:122959. doi:10.1016/j.jhazmat.2020.122959 |

| 6 | 房德职,李克勋 .国内外生活垃圾焚烧发电技术进展[J].发电技术,2019,40(4):367-376. doi:10.12096/j.2096-4528.pgt.18234 |

| FANG D Z, LI K X .An overview of power generation from municipal solid waste incineration plants at home and abroad[J].Power Generation Technology,2019,40(4):367-376. doi:10.12096/j.2096-4528.pgt.18234 | |

| 7 | MONTIEL-BOHÓRQUEZ N D, AGUDELO A F, PÉREZ J F .Effect of origin and production rate of MSW on the exergoeconomic performance of an integrated plasma gasification combined cycle power plant[J].Energy Conversion and Management,2021,238:114138. doi:10.1016/j.enconman.2021.114138 |

| 8 | KULKARNI B N .Environmental sustainability assessment of land disposal of municipal solid waste generated in Indian cities:a review[J].Environmental Development,2020,33:100490. doi:10.1016/j.envdev.2019.100490 |

| 9 | 郑妍,姚宣,陈训强 .生物质气化耦合发电体系的合成气组分与能量分析[J].发电技术,2023,44(6):859-864. doi:10.12096/j.2096-4528.pgt.22164 |

| ZHENG Y, YAO X, CHEN X Q .Analysis of syngas components and energy in biomass gasification coupled power generation system[J].Power Generation Technology,2023,44(6):859-864. doi:10.12096/j.2096-4528.pgt.22164 | |

| 10 | MAZZONI L, AHMED R, JANAJREH I .Plasma gasification of two waste streams:municipal solid waste and hazardous waste from the oil and gas industry[J].Energy Procedia,2017,105:4159-4166. doi:10.1016/j.egypro.2017.03.882 |

| 11 | MAZZONI L, JANAJREH I .Plasma gasification of municipal solid waste with variable content of plastic solid waste for enhanced energy recovery[J].International Journal of Hydrogen Energy,2017,42(30):19446-19457. doi:10.1016/j.ijhydene.2017.06.069 |

| 12 | OWEBOR K, OKO C O C, DIEMUODEKE E O,et al .Thermo-environmental and economic analysis of an integrated municipal waste-to-energy solid oxide fuel cell,gas-,steam-,organic fluid- and absorption refrigeration cycle thermal power plants[J].Applied Energy,2019,239:1385-1401. doi:10.1016/j.apenergy.2019.02.032 |

| 13 | BELLOMARE F, ROKNI M .Integration of a municipal solid waste gasification plant with solid oxide fuel cell and gas turbine[J].Renewable Energy,2013,55:490-500. doi:10.1016/j.renene.2013.01.016 |

| 14 | PAULINO R F S, ESSIPTCHOUK A M, SILVEIRA J L .The use of syngas from biomedical waste plasma gasification systems for electricity production in internal combustion:thermodynamic and economic issues[J].Energy,2020,199:117419. doi:10.1016/j.energy.2020.117419 |

| 15 | 高哈尔⋅努拉里,李国峰,古丽娜尔⋅图尔逊 .废旧轮胎的资源化与无害化技术现状与研究[J].合成材料老化与应用,2022,51(2):117-118. |

| NULALI G, LI G F, TURSEN G .Current situation and research on recycling and harmless technology of waste tire[J].Synthetic Materials Aging and Application,2022,51(2):117-118. | |

| 16 | MAVUKWANA A E, STACEY N, FOX J A,et al .Thermodynamic comparison of pyrolysis and gasification of waste tyres[J].Journal of Environmental Chemical Engineering,2021,9(2):105163. doi:10.1016/j.jece.2021.105163 |

| 17 | 蔡杰 .基于ASPEN Plus的村镇垃圾热解气化燃烧模拟与试验[D].杭州:浙江大学,2021. |

| CAI J .Simulation and experiment of pyrolysis,gasification and combustion of village waste based on aspen plus[D].Hangzhou:Zhejiang University,2021. | |

| 18 | 邢岳,谭浩艺,裴东升,等 .直接空冷乏汽提质供热系统变工况特性研究[J].浙江电力,2023,42(11):122-128. |

| XING Y, TAN H Y, PEI D S,et al .A study on variable operating characteristics of a direct air-cooling exhaust steam extraction heat supply system[J].Zhejiang Electric Power,2023,42(11):122-128. | |

| 19 | KHOSHGOFTAR MANESH M H, FIROUZI P, KABIRI S,et al .Evaluation of power and freshwater production based on integrated gas turbine,S-CO2,and ORC cycles with RO desalination unit[J].Energy Conversion and Management,2021,228:113607. doi:10.1016/j.enconman.2020.113607 |

| 20 | ERDOGAN A A, YILMAZOGLU M Z .Plasma gasification of the medical waste[J].International Journal of Hydrogen Energy,2021,46(57):29108-29125. doi:10.1016/j.ijhydene.2020.12.069 |

| 21 | MINUTILLO M, PERNA A, DI BONA D .Modelling and performance analysis of an integrated plasma gasification combined cycle (IPGCC) power plant[J].Energy Conversion and Management,2009,50(11):2837-2842. doi:10.1016/j.enconman.2009.07.002 |

| 22 | ISMAIL H Y, ABBAS A, AZIZI F,et al .Pyrolysis of waste tires:a modeling and parameter estimation study using Aspen Plus®[J].Waste Management,2017,60:482-493. doi:10.1016/j.wasman.2016.10.024 |

| 23 | TAJIK MANSOURI M, AHMADI P, GANJEH KAVIRI A,et al .Exergetic and economic evaluation of the effect of HRSG configurations on the performance of combined cycle power plants[J].Energy Conversion and Management,2012,58:47-58. doi:10.1016/j.enconman.2011.12.020 |

| 24 | VILARDI G, VERDONE N .Exergy analysis of municipal solid waste incineration processes:the use of O 2 - enriched air and the oxy-combustion process[J].Energy,2022,239:122147. doi:10.1016/j.energy.2021.122147 |

| 25 | GALENO G, MINUTILLO M, PERNA A .From waste to electricity through integrated plasma gasification/fuel cell (IPGFC) system[J].International Journal of Hydrogen Energy,2011,36(2):1692-1701. doi:10.1016/j.ijhydene.2010.11.008 |

| 26 | MINUTILLO M, PERNA A, DI BONA D .Modelling and performance analysis of an integrated plasma gasification combined cycle (IPGCC) power plant[J].Energy Conversion and Management,2009,50(11):2837-2842. doi:10.1016/j.enconman.2009.07.002 |

| 27 | LAI H, HARUN N F, TUCKER D,et al .Design and eco-technoeconomic analyses of SOFC/GT hybrid systems accounting for long-term degradation effects[J].International Journal of Hydrogen Energy,2021,46(7):5612-5629. doi:10.1016/j.ijhydene.2020.11.032 |

| 28 | ALNOUSS A, MCKAY G, AL-ANSARI T .A techno-economic-environmental study evaluating the potential of oxygen-steam biomass gasification for the generation of value-added products[J].Energy Conversion and Management,2019,196:664-676. doi:10.1016/j.enconman.2019.06.019 |

| 29 | PENG W, CHEN H, LIU J,et al .Techno-economic assessment of a conceptual waste-to-energy CHP system combining plasma gasification,SOFC,gas turbine and supercritical CO2 cycle[J].Energy Conversion and Management,2021,245:114622. doi:10.1016/j.enconman.2021.114622 |

| 30 | CHEN H, LI J, LI T,et al .Performance assessment of a novel medical-waste-to-energy design based on plasma gasification and integrated with a municipal solid waste incineration plant[J].Energy,2022,245:123156. doi:10.1016/j.energy.2022.123156 |

| 31 | ZHANG Z, DELCROIX B, REZAZGUI O,et al .Simulation and techno-economic assessment of bio-methanol production from pine biomass,biochar and pyrolysis oil[J].Sustainable Energy Technologies and Assessments,2021,44:101002. doi:10.1016/j.seta.2021.101002 |

| 32 | 彭维珂,李童宇,武浩然,等 .基于医疗垃圾等离子气化的零碳高效热电联产系统性能分析[J].中国电机工程学报,2022,42(9):3135-3151. doi:10.13334/j.0258-8013.pcsee.212683 |

| PENG W K, LI T Y, WU H R,et al . Performance assessment of a zero-carbon emission waste-to-energy CHP hybrid system based on plasma gasification[J].Proceedings of the CSEE,2022,42(9):3135-3151. doi:10.13334/j.0258-8013.pcsee.212683 | |

| 33 | DINCA C, SLAVU N, CORMOŞ C C,et al .CO2 capture from syngas generated by a biomass gasification power plant with chemical absorption process[J].Energy,2018,149:925-936. doi:10.1016/j.energy.2018.02.109 |

| 34 | MONTIEL-BOHÓRQUEZ N D, AGUDELO A F, PÉREZ J F .Effect of origin and production rate of MSW on the exergoeconomic performance of an integrated plasma gasification combined cycle power plant[J].Energy Conversion and Management,2021,238:114138. doi:10.1016/j.enconman.2021.114138 |

| 35 | NAMI H, MAHMOUDI S M S, NEMATI A .Exergy,economic and environmental impact assessment and optimization of a novel cogeneration system including a gas turbine,a supercritical CO2 and an organic Rankine cycle (GT-HRSG/SCO2)[J].Applied Thermal Engineering,2017,110:1315-1330. doi:10.1016/j.applthermaleng.2016.08.197 |

| 36 | QIN Z, TANG Y, ZHANG Z,et al .Techno-economic-environmental analysis of coal-based methanol and power poly-generation system integrated with biomass co-gasification and solar based hydrogen addition[J].Energy Conversion and Management,2021,228:113646. doi:10.1016/j.enconman.2020.113646 |

| [1] | 崔则阳, 孔祥玲, 付经伦, 施佳君. 一种基于图像的燃气轮机叶型参数测量方法[J]. 发电技术, 2024, 45(1): 106-112. |

| [2] | 杨旸, 李耀强, 张金琦. 基于数值方法的燃气轮机贫预混旋流燃烧室单头部结构设计[J]. 发电技术, 2023, 44(5): 712-721. |

| [3] | 杨旸, 郭德三, 李耀强, 张金琦. 燃气轮机贫预混多旋流组合燃烧室头部结构设计[J]. 发电技术, 2023, 44(2): 183-192. |

| [4] | 张弘毅, 曲立涛. 9F级燃机选择性催化还原脱硝数值模拟研究与应用[J]. 发电技术, 2023, 44(1): 78-84. |

| [5] | 金云峰, 刘超, 邓高峰, 关运龙, 郝建刚, 黄海舟, 蒋东翔. 燃气轮机进气过滤系统维修周期经济性分析[J]. 发电技术, 2022, 43(1): 119-125. |

| [6] | 白明亮, 张冬雪, 刘金福, 刘娇, 于达仁. 基于深度自编码器和支持向量数据描述的燃气轮机高温部件异常检测[J]. 发电技术, 2021, 42(4): 422-430. |

| [7] | 孔祥玲, 付经伦. 基于计算机视觉的三维重建技术在燃气轮机行业的应用及展望[J]. 发电技术, 2021, 42(4): 454-463. |

| [8] | 邱彬, 付经伦. 燃气轮机排气扩压器研究现状[J]. 发电技术, 2021, 42(4): 437-446. |

| [9] | 魏凯, 罗忠, 孙永航, 王宇. 燃气轮机带阀片引射混合器内流特性分析[J]. 发电技术, 2021, 42(4): 431-436. |

| [10] | 朱华, 严彪, 刘雨松, 李亮. 湿空气透平冷却技术研究[J]. 发电技术, 2021, 42(4): 412-421. |

| [11] | 管金, 何宗泽, 吕小静, 翁一武. 30kW微型燃气轮机发电机组启动实验研究[J]. 发电技术, 2021, 42(4): 404-411. |

| [12] | 金云峰, 刘超, 邓高峰, 关运龙, 田鑫, 黄海舟, 蒋东翔. 燃气轮机进气压差建模方法研究[J]. 发电技术, 2021, 42(4): 395-403. |

| [13] | 黄友华, 马善为, 刘吉, 武正华. 燃气轮机烟气SCR脱硝系统优化设计与工程应用[J]. 发电技术, 2021, 42(3): 350-356. |

| [14] | 方继辉,王荣. 重型F级燃气轮机IGV开度对压气机效率的影响[J]. 发电技术, 2020, 41(3): 317-319. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||