发电技术 ›› 2023, Vol. 44 ›› Issue (5): 712-721.DOI: 10.12096/j.2096-4528.pgt.21109

杨旸1,2, 李耀强3, 张金琦3

收稿日期:2022-11-25

出版日期:2023-10-31

发布日期:2023-10-30

作者简介:基金资助:Yang YANG1,2, Yaoqiang LI3, Jinqi ZHANG3

Received:2022-11-25

Published:2023-10-31

Online:2023-10-30

Supported by:摘要:

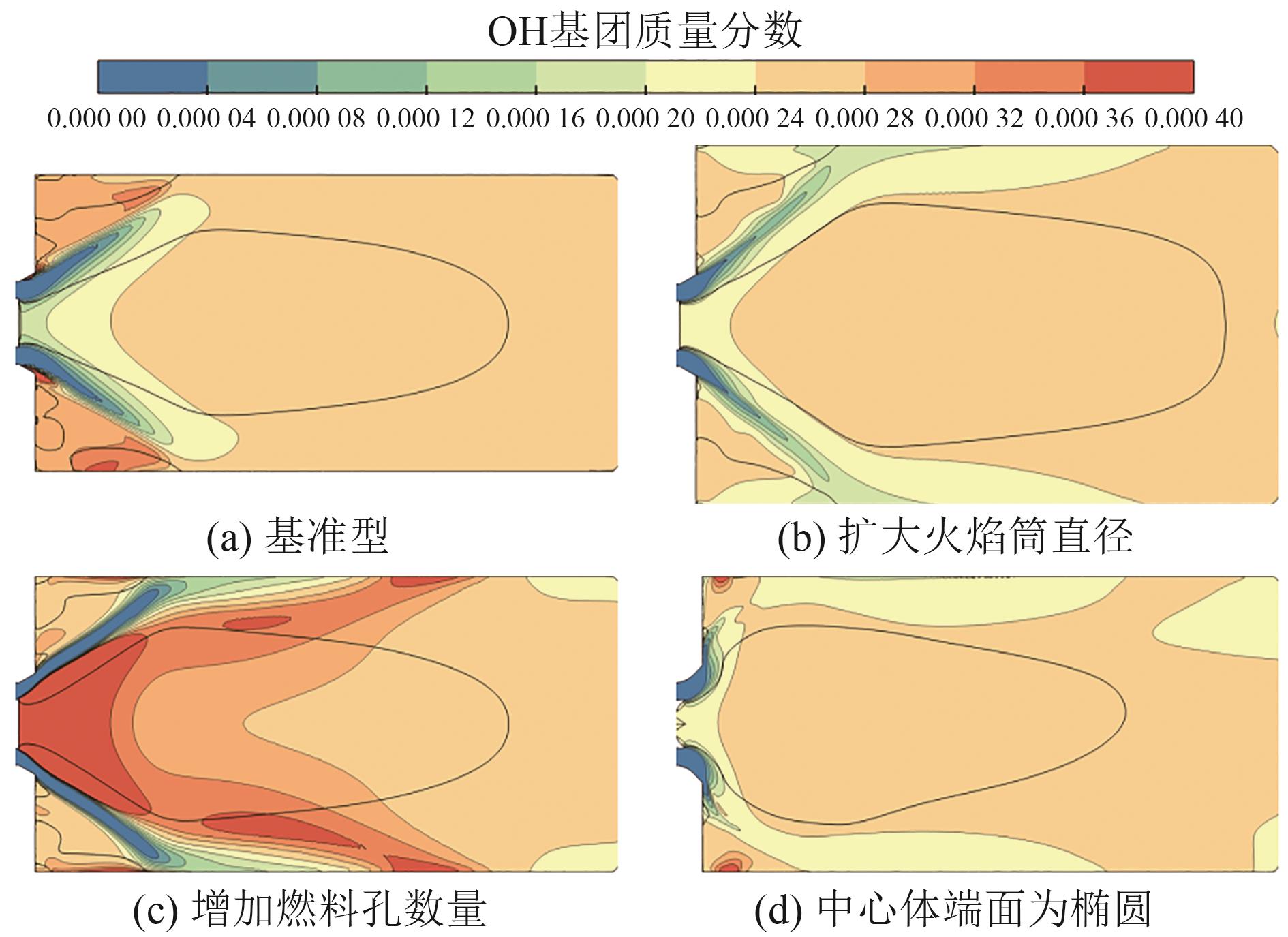

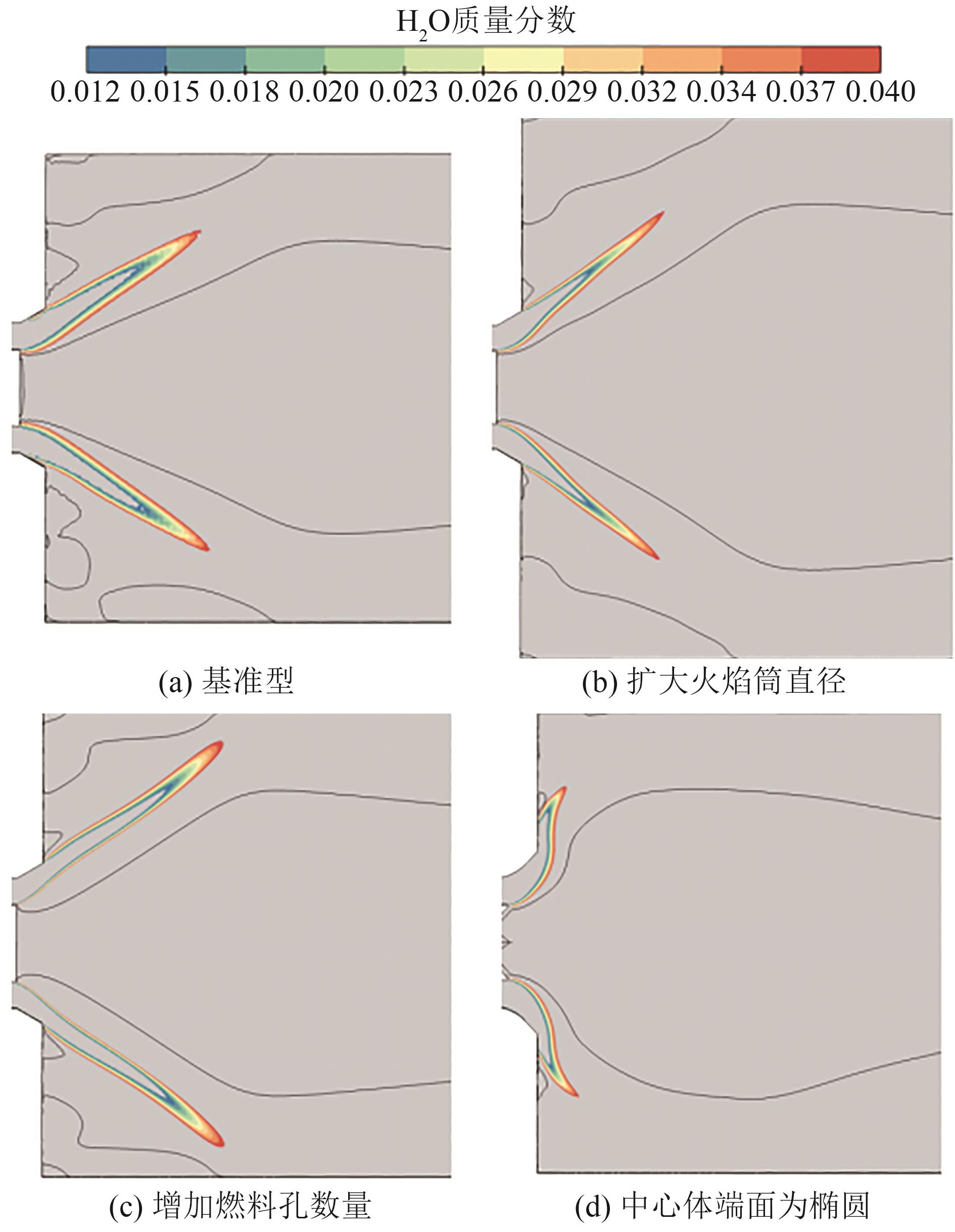

为分析贫预混旋流燃烧室头部结构特性影响,采用计算流体力学方法研究了中心体端面形状、空气流量,燃料喷孔数量、位置,以及头部扩张比对燃烧火焰、流场及火焰动态响应的影响。结果表明:空气流速增大到一定值后, 火焰形态基本保持不变;增加压力面燃料孔数量,高放热率区集中在中心回流区根部,同时增加压力面和吸力面燃料孔数量使得中心回流区根部温度更低,有降低热力NO x 的趋势;增加火焰筒直径,有助于中心回流区沿径向扩张,导致火焰更长、更细;将中心体端面改成椭圆,会缩短火焰轴向长度;改变中心体端面形状基本不影响火焰传递函数幅值和相位,但增加燃料孔数量明显改变火焰传递函数相位。

中图分类号:

杨旸, 李耀强, 张金琦. 基于数值方法的燃气轮机贫预混旋流燃烧室单头部结构设计[J]. 发电技术, 2023, 44(5): 712-721.

Yang YANG, Yaoqiang LI, Jinqi ZHANG. Design of Dome Structure for A Lean Premixed Swirled Combustor of Gas Turbine Based on the Numerical Method[J]. Power Generation Technology, 2023, 44(5): 712-721.

| 边界 | 参数 | 空气 进口 | 燃料吸力面 | 燃料压力面 | 燃烧器出口 | 燃料质量分数/% |

|---|---|---|---|---|---|---|

| 1 | 速度/(m/s) | 18.00 | 25.64 | 26.30 | 11.98 | 2.9 |

| 流量/(g/s) | 19.87 | 0.30 | 0.30 | 20.47 | ||

| 2 | 速度/(m/s) | 35.00 | 49.90 | 51.18 | 22.54 | 2.9 |

| 流量/(g/s) | 38.63 | 0.58 | 0.58 | 39.80 | ||

| 3 | 速度/(m/s) | 50.00 | 60.22 | 61.77 | 29.93 | 2.5 |

| 流量/(g/s) | 55.19 | 0.70 | 0.70 | 56.59 | ||

| 4 | 速度/(m/s) | 50.00 | 71.23 | 73.07 | 32.20 | 2.9 |

| 流量/(g/s) | 55.19 | 0.83 | 0.83 | 56.85 | ||

| 5 | 速度/(m/s) | 75.00 | 106.85 | 109.60 | 48.25 | 2.9 |

| 流量/(g/s) | 82.79 | 1.24 | 1.24 | 85.28 |

表1 不同空气流速下工况及边界条件

Tab. 1 Boundary conditions of cases with different velocities and mass flow rates

| 边界 | 参数 | 空气 进口 | 燃料吸力面 | 燃料压力面 | 燃烧器出口 | 燃料质量分数/% |

|---|---|---|---|---|---|---|

| 1 | 速度/(m/s) | 18.00 | 25.64 | 26.30 | 11.98 | 2.9 |

| 流量/(g/s) | 19.87 | 0.30 | 0.30 | 20.47 | ||

| 2 | 速度/(m/s) | 35.00 | 49.90 | 51.18 | 22.54 | 2.9 |

| 流量/(g/s) | 38.63 | 0.58 | 0.58 | 39.80 | ||

| 3 | 速度/(m/s) | 50.00 | 60.22 | 61.77 | 29.93 | 2.5 |

| 流量/(g/s) | 55.19 | 0.70 | 0.70 | 56.59 | ||

| 4 | 速度/(m/s) | 50.00 | 71.23 | 73.07 | 32.20 | 2.9 |

| 流量/(g/s) | 55.19 | 0.83 | 0.83 | 56.85 | ||

| 5 | 速度/(m/s) | 75.00 | 106.85 | 109.60 | 48.25 | 2.9 |

| 流量/(g/s) | 82.79 | 1.24 | 1.24 | 85.28 |

| 工况 | 孔数 | 压力面喷孔 | 吸力面喷孔 | ||||

|---|---|---|---|---|---|---|---|

| 面积/mm2 | 速度/(m/s) | 流量/(g/s) | 面积/mm2 | 速度/(m/s) | 流量/(g/s) | ||

| 基准型 | 压力面、吸力面各2孔 | 17.9 | 71.23 | 0.83 | 17.4 | 73.07 | 0.83 |

| 改型1 | 压力面、吸力面各4孔 | 34.9 | 36.57 | 0.83 | 34.4 | 37.05 | 0.83 |

| 改型2 | 压力面4孔 | 34.9 | 73.13 | 1.66 | 0 | 0 | 0 |

| 改型3 | 吸力面4孔 | 0 | 0 | 0 | 34.4 | 74.09 | 1.66 |

表2 不同燃料喷嘴参数及边界条件

Tab. 2 Parameters and boundary conditions of different fuel nozzles

| 工况 | 孔数 | 压力面喷孔 | 吸力面喷孔 | ||||

|---|---|---|---|---|---|---|---|

| 面积/mm2 | 速度/(m/s) | 流量/(g/s) | 面积/mm2 | 速度/(m/s) | 流量/(g/s) | ||

| 基准型 | 压力面、吸力面各2孔 | 17.9 | 71.23 | 0.83 | 17.4 | 73.07 | 0.83 |

| 改型1 | 压力面、吸力面各4孔 | 34.9 | 36.57 | 0.83 | 34.4 | 37.05 | 0.83 |

| 改型2 | 压力面4孔 | 34.9 | 73.13 | 1.66 | 0 | 0 | 0 |

| 改型3 | 吸力面4孔 | 0 | 0 | 0 | 34.4 | 74.09 | 1.66 |

| 参数 | 工况 | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| 空气流速/(m/s) | 18 | 35 | 50 | 75 |

| 折算热功率/(MW/MPa) | 0.332 | 0.645 | 0.921 | 1.383 |

表3 不同空气流速及相应热功率工况

Tab. 3 Different air flow rates and corresponding thermal power conditions

| 参数 | 工况 | |||

|---|---|---|---|---|

| 1 | 2 | 3 | 4 | |

| 空气流速/(m/s) | 18 | 35 | 50 | 75 |

| 折算热功率/(MW/MPa) | 0.332 | 0.645 | 0.921 | 1.383 |

| 结构 | 压力面燃料孔个数 | 吸力面燃料孔个数 |

|---|---|---|

| 基准型 | 2 | 2 |

| 改型1 | 4 | 4 |

| 改型2 | 4 | 0 |

| 改型3 | 0 | 4 |

表4 各形式燃料孔

Tab. 4 Different fuel hole structures

| 结构 | 压力面燃料孔个数 | 吸力面燃料孔个数 |

|---|---|---|

| 基准型 | 2 | 2 |

| 改型1 | 4 | 4 |

| 改型2 | 4 | 0 |

| 改型3 | 0 | 4 |

图11 4种不同头部结构的燃烧中间产物OH基团的质量分数分布云图

Fig. 11 Cloud diagrams of mass fraction distribution of OH groups in combustion intermediates with four different head structures

图12 4种不同头部结构的燃烧最终产物H2O的质量分数分布云图

Fig. 12 Cloud diagram of mass fraction distribution of H2O, the final combustion product with four different head structures

| 1 | LEFEBVRE A H, BALLAL D R .Gas turbine combustion:alternative fuels and emissions[M].Karabas:CRC Press,2010. doi:10.1201/9781420086058 |

| 2 | GOLDMEER J, YORK W, GLASER P .Fuel and combustion system capabilities of GE’s F and HA class gas turbines[C]//ASME Turbo Expo:Turbomachinery Technical Conference & Exposition.Charlotte,North Carolina,USA:ASME,2017:64588. doi:10.1115/gt2017-64588 |

| 3 | 田晓晶,崔玉峰,邢双喜,等 .预混段结构对旋流预混氢火焰回火形式影响的数值研究[J].推进技术,2015,36(3):345-351. doi:10.13675/j.cnki.tjjs.2015.03.004 |

| TIAN X J, CUI Y F, XING S X,et al .Numerical investigation on effects of mixing zone structure on flashback type for swirl-premixed hydrogen flame[J].Journal of Propulsion Technology,2015,36(3):345-351. doi:10.13675/j.cnki.tjjs.2015.03.004 | |

| 4 | HUANG Y, YANG V .Effect of swirl on combustion dynamics in a lean-premixed swirl-stabilized combustor[J].Proceedings of the Combustion Institute,2005,30(2):1775-1782. doi:10.1016/j.proci.2004.08.237 |

| 5 | 杨旸,陈明敏,刘潇,等 .天然气低排放旋流燃烧室头部结构性能研究[J].燃气轮机技术,2020,33(1):25-31. |

| YANG Y, CHEN M M, LIU X,et al .Research on design and performance of swirl combustor for low emission natural gas turbine[J].Gas Turbine Technology,2020,33(1):25-31. | |

| 6 | 祝俊宗,胡羽,夏单城,等 .改善低 NO x 燃烧室预混均匀性的结构优化策略[J].中国电机工程学报,2017,37(21):6353-6362. doi:10.13334/j.0258-8013.pcsee.162186 |

| ZHU J Z, HU Y, XIA D C,et al .Structural optimization strategy of improving the premixing uniformity in a low NO x combustor[J].Proceedings of the CSEE,2017,37(21):6353-6362. doi:10.13334/j.0258-8013.pcsee.162186 | |

| 7 | YANG Y, NOIRAY N, SCARPATO A,et al .Numerical analysis of the dynamic flame response in Alstom reheat combustion systems[C]//ASME Turbo Exposition:Turbine Technical Conference & Exposition.Montreal,Canada:ASME,2015:42622. doi:10.1115/gt2015-42622 |

| 8 | YANG Y, LIU X, ZHANG Z H .Large eddy simulation calculated flame dynamics of one F-class gas turbine combustor[J].Fuel,2020,261:116451. doi:10.1016/j.fuel.2019.116451 |

| 9 | 管金,何宗泽,吕小静,等 .30 kW微型燃气轮机发电机组启动实验研究[J].发电技术,2021,42(4):404-411. doi:10.12096/j.2096-4528.pgt.21086 |

| GUAN J, HE Z Z, LÜ X J,et al .Experimental study on startup of 30 kW micro gas turbine generator set[J].Power Generation Technology,2021,42(4):404-411. doi:10.12096/j.2096-4528.pgt.21086 | |

| 10 | POLIFKE W .Modeling and analysis of premixed flame dynamics by means of distributed time delays[J].Progress in Energy and Combustion Science,2020,79:100845. doi:10.1016/j.pecs.2020.100845 |

| 11 | GREGORY P S, DAVID M G, MICHAEL F,et al .GRI-Mech 3.0[EB/OL].Berkeley,CA:University of California,(2000-02-15)[2021-10-05].. |

| 12 | ZIMONT V, POLIFKE W, BETTELINI M,et al. An efficient computational model for premixed turbulent combustion at high Reynolds numbers based on a turbulent flame speed closure[J].Journal of Engineering for Gas Turbines and Power,1998,120:526. doi:10.1115/1.2818178 |

| 13 | DOBBELING K, HELLAT J, KOCH H .25 years of BBC/ABB/Alstom lean premix combustion technologies [C]//Turbo Expo:Power for Land,Sea,and Air.Nevada,USA:ASME,2005:201-213. doi:10.1115/gt2005-68269 |

| 14 | CHONG L TAY WO, KOMAREK T, KAESS R,et al .Identification of flame transfer functions from LES of a premixed swirl burner[C]//Turbo Expo:Power for Land,Sea,and Air.Glasgow,UK:ASME,2010:623-635. doi:10.1115/gt2010-22769 |

| 15 | INNOCENTI A, ANDREINI A, FACCHINI B,et al .Numerical analysis of the dynamic flame response of a spray flame for aero-engine applications[J].International Journal of Spray and Combustion Dynamics,2017,9(4):310-329. doi:10.1177/1756827717703577 |

| 16 | ISERMANN R, MÜNCHHOF M .Identification of dynamic systems:an introduction with applications[M].Germany:Springer Science & Business Media,2010. doi:10.1007/978-3-540-78879-9_22 |

| 17 | GUPTA A K, LILLEY D G, SYRED N .Swirl flows[M].Tunbridge Wells:Abacus Press,1984. |

| [1] | 屠楠, 刘家琛, 徐静, 方嘉宾, 马彦花. 管壳式相变蓄热器的蓄释热过程性能分析[J]. 发电技术, 2024, 45(3): 508-516. |

| [2] | 刘学, 李国栋, 张瑞颖, 侯一晨, 陈磊, 杨立军. 电站空冷岛轴流风机模型研究[J]. 发电技术, 2024, 45(3): 545-557. |

| [3] | 蒋海威, 高明明, 李杰, 于浩洋, 岳光溪, 黄中. 生物质振动炉排炉燃烧过程建模及动态特性分析[J]. 发电技术, 2024, 45(2): 250-259. |

| [4] | 龚思琦, 云再鹏, 许明, 敖乐, 李初福, 黄凯, 孙晨. 基于三元催化剂的固体氧化物燃料电池尾气催化燃烧数值模拟[J]. 发电技术, 2024, 45(2): 331-340. |

| [5] | 崔则阳, 孔祥玲, 付经伦, 施佳君. 一种基于图像的燃气轮机叶型参数测量方法[J]. 发电技术, 2024, 45(1): 106-112. |

| [6] | 杨旸, 郭德三, 李耀强, 张金琦. 燃气轮机贫预混多旋流组合燃烧室头部结构设计[J]. 发电技术, 2023, 44(2): 183-192. |

| [7] | 刘文斌, 李璐璐, 李晓金, 姚宣, 杨海瑞. 脱硫湿烟气喷淋冷凝过程中的参数优化研究[J]. 发电技术, 2023, 44(1): 107-114. |

| [8] | 吴荣辉, 刘冬, 郁冶, 牟凯龙, 赵兰浩. 基于浸入边界法的海上风电双向流固耦合数值模拟方法[J]. 发电技术, 2023, 44(1): 44-52. |

| [9] | 张弘毅, 曲立涛. 9F级燃机选择性催化还原脱硝数值模拟研究与应用[J]. 发电技术, 2023, 44(1): 78-84. |

| [10] | 孔文俊, 张艳森, 汤效平, 张伟阔. 大容量储能锂电池电芯产热特性研究[J]. 发电技术, 2022, 43(5): 801-809. |

| [11] | 王泽旭, 李冰辰, 许瑶, 刘倩, 李凯璇, 巨星. 基于过冷相变材料热开关的锂离子电池热管理系统[J]. 发电技术, 2022, 43(2): 328-340. |

| [12] | 金云峰, 刘超, 邓高峰, 关运龙, 郝建刚, 黄海舟, 蒋东翔. 燃气轮机进气过滤系统维修周期经济性分析[J]. 发电技术, 2022, 43(1): 119-125. |

| [13] | 高垚楠, 陈海峰, 王建永. 一种新型CO2工质冷热电联供系统的热力性分析[J]. 发电技术, 2022, 43(1): 131-138. |

| [14] | 戴春喜, 梁平, 车德勇, 刘海婷. 蜂窝管湿式电除尘器内部流动特性研究[J]. 发电技术, 2022, 43(1): 155-159. |

| [15] | 廖志荣, 李朋达, 田紫芊, 徐超, 魏高升. 非均匀翅片对级联相变储热系统热性能强化的研究[J]. 发电技术, 2022, 43(1): 83-91. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||