Power Generation Technology ›› 2021, Vol. 42 ›› Issue (4): 500-508.DOI: 10.12096/j.2096-4528.pgt.21001

• Intelligent Turbine Power Generation Technology • Previous Articles Next Articles

Changchun LIU( ), Chun GUAN(

), Chun GUAN( ), Kuijun GUO(

), Kuijun GUO( ), Yufeng LI(

), Yufeng LI( ), Yiliang MA(

), Yiliang MA( )

)

Received:2021-01-19

Published:2021-08-31

Online:2021-07-22

CLC Number:

Changchun LIU, Chun GUAN, Kuijun GUO, Yufeng LI, Yiliang MA. Flutter Prediction Method for Long Blade of Steam Turbine[J]. Power Generation Technology, 2021, 42(4): 500-508.

| 材料参数 | 设计参数 | |||

| 参数 | 数值 | 参数 | 数值 | |

| 材料 | 0Cr17 | 设计转速/(r/min) | 3 600 | |

| 密度/(kg/m3) | 7 780 | 数量 | 68 | |

| 泊松比 | 0.3 | 叶高/mm | 441.5 | |

| 弹性模量/MPa | 213 000 | 设计流量/(t/h) | 325.8 | |

Tab. 1 Rotor materials and design parameters

| 材料参数 | 设计参数 | |||

| 参数 | 数值 | 参数 | 数值 | |

| 材料 | 0Cr17 | 设计转速/(r/min) | 3 600 | |

| 密度/(kg/m3) | 7 780 | 数量 | 68 | |

| 泊松比 | 0.3 | 叶高/mm | 441.5 | |

| 弹性模量/MPa | 213 000 | 设计流量/(t/h) | 325.8 | |

| 工况 | 进口模式 | 进口压力/Pa | 进口温度/K | 出口模式 | 出口压力/Pa | 出口温度/K |

| 100%流量 | Inlet | 51 552.6 | 357.2 | Outlet | 31 110.0 | — |

| 40%流量 | Opening | 33 615.1 | 344.3 | Opening | 31 110.0 | 343.1 |

Tab. 2 Boundary conditions of calculation domain

| 工况 | 进口模式 | 进口压力/Pa | 进口温度/K | 出口模式 | 出口压力/Pa | 出口温度/K |

| 100%流量 | Inlet | 51 552.6 | 357.2 | Outlet | 31 110.0 | — |

| 40%流量 | Opening | 33 615.1 | 344.3 | Opening | 31 110.0 | 343.1 |

| 项目 | 单向流固耦合 | 双向流固耦合 |

| 计算对象 | 周期功、气动阻尼系数 | 非定常力、振动位移 |

| 假设条件 | 叶片做恒幅振动;频率为某阶固有频率;指定叶间相位角 | 仅考虑汽流力的影响;叶间相位角由计算流道数决定 |

| 简化程度 | 只需计算两流道 | 一般需全周计算 |

| 输入参数 | 入口、出口工况参数 | 入口、出口工况参数 |

| 传递参数 | 流场压力数据;该工况某一节径振动频率下单只叶片各个节点x, y, z三个方向的网格位移数据 | 流场压力数据;结构场网格位移数据 |

| 目标差异 | 旨在获得叶片气动阻尼与振型、叶间相位角的关系,依据气动阻尼正负判断节径振动是否会激发颤振 | 旨在获得汽流激振力作用下流场–叶片的耦合作用,依据振动位移收敛性来判断颤振是否发生 |

| 预测评价 | 基于模态共振条件来预测颤振,结果偏保守,计算量较小,适合工程应用 | 仅考虑了汽流力作用来判断颤振,结果有风险,计算量大,计算机配置要求高 |

Tab. 3 Comparison of two liquid-solid coupling methods on flutter evaluation

| 项目 | 单向流固耦合 | 双向流固耦合 |

| 计算对象 | 周期功、气动阻尼系数 | 非定常力、振动位移 |

| 假设条件 | 叶片做恒幅振动;频率为某阶固有频率;指定叶间相位角 | 仅考虑汽流力的影响;叶间相位角由计算流道数决定 |

| 简化程度 | 只需计算两流道 | 一般需全周计算 |

| 输入参数 | 入口、出口工况参数 | 入口、出口工况参数 |

| 传递参数 | 流场压力数据;该工况某一节径振动频率下单只叶片各个节点x, y, z三个方向的网格位移数据 | 流场压力数据;结构场网格位移数据 |

| 目标差异 | 旨在获得叶片气动阻尼与振型、叶间相位角的关系,依据气动阻尼正负判断节径振动是否会激发颤振 | 旨在获得汽流激振力作用下流场–叶片的耦合作用,依据振动位移收敛性来判断颤振是否发生 |

| 预测评价 | 基于模态共振条件来预测颤振,结果偏保守,计算量较小,适合工程应用 | 仅考虑了汽流力作用来判断颤振,结果有风险,计算量大,计算机配置要求高 |

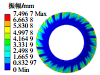

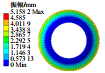

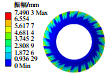

| 工况 | 子系统 | 最大压力/Pa | 最小压力/Pa | 节点数 | 数据传递 |

| 100%流量 | 流场 | 66 220 | 21 450 | 14 496 | 100% |

| 结构场 | 67 061 | 23 137 | 13 700 | ||

| 40%流量 | 流场 | 61 530 | 10 260 | 14 496 | 100% |

| 结构场 | 61 172 | 10 534 | 13 700 |

Tab. 4 Pressure mapping results of liquid-solid coupling surface

| 工况 | 子系统 | 最大压力/Pa | 最小压力/Pa | 节点数 | 数据传递 |

| 100%流量 | 流场 | 66 220 | 21 450 | 14 496 | 100% |

| 结构场 | 67 061 | 23 137 | 13 700 | ||

| 40%流量 | 流场 | 61 530 | 10 260 | 14 496 | 100% |

| 结构场 | 61 172 | 10 534 | 13 700 |

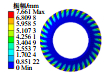

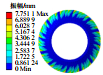

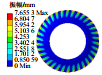

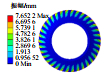

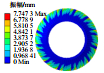

| 频率 | NND=−17 | NND=0 | NND=12 | NND=17 | NND=20 |

| 静频 | 103.22 | 102.46 | 102.88 | 103.22 | 103.43 |

| 100%流量动频 | 180.11 | 176.49 | 178.55 | 180.11 | 181.02 |

| 40%流量动频 | 180.74 | 177.30 | 179.26 | 180.74 | 181.60 |

Tab. 5 First order modal vibration frequency of blade Hz

| 频率 | NND=−17 | NND=0 | NND=12 | NND=17 | NND=20 |

| 静频 | 103.22 | 102.46 | 102.88 | 103.22 | 103.43 |

| 100%流量动频 | 180.11 | 176.49 | 178.55 | 180.11 | 181.02 |

| 40%流量动频 | 180.74 | 177.30 | 179.26 | 180.74 | 181.60 |

| 工况 | NND=−17 | NND=0 | NND=12 | NND=17 | NND=20 |

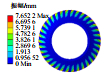

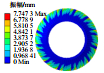

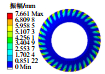

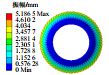

| 100%流量 |  |  |  |  |  |

| 40%流量 |  |  |  |  |  |

Tab. 6 First order modal vibration mode of blade

| 工况 | NND=−17 | NND=0 | NND=12 | NND=17 | NND=20 |

| 100%流量 |  |  |  |  |  |

| 40%流量 |  |  |  |  |  |

| 1 |

李宇峰, 任大康, 黄钢, 等. 空冷汽轮机低压末级变工况设计[J]. 热力透平, 2004, 33 (1): 14- 16.

DOI |

|

LI Y F , REN D K , HUANG G , et al. The off-design for LP last stage blade of air-cooling units[J]. Thermal Turbine, 2004, 33 (1): 14- 16.

DOI |

|

| 2 |

刘万琨. 汽轮机末级叶片颤振设计[J]. 东方电气评论, 2007, 21 (4): 7- 13.

DOI |

|

LIU W K . Flutter design for steam turbine last blade[J]. Dongfang Electric Review, 2007, 21 (4): 7- 13.

DOI |

|

| 3 | 陶德平, 杨晓东, 周盛. 蒸汽轮机长叶片颤振预估方法研究[J]. 航空动力学报, 1991, (2): 151- 156. |

| TAO D P , YANG X D , ZHOU S . Prediction of long blade flutter in a steam turbine[J]. Journal of Aerospace Power, 1991, (2): 151- 156. | |

| 4 |

张扬军, 陶德平. 汽轮机叶片颤振研究的新进展[J]. 科学通报, 1996, (23): 2204- 2206.

DOI |

|

ZHANG Y J , TAO D P . New progress in research on blade flutter of steam turbine[J]. Chinese Science Bulletin, 1996, (23): 2204- 2206.

DOI |

|

| 5 | 张扬军, 陶德平. 变叶片间相角的蒸汽轮机叶片颤振预测方法[J]. 水利电力机械, 1993, (4): 29- 32. |

| ZHANG Y J , TAO D P . Prediction method of steam turbine blade flutter with variable blade phase angle[J]. Hydraulic and Electric Machinery, 1993, (4): 29- 32. | |

| 6 | 张扬军, 李克俭, 陶德平. 叶片间相角对蒸汽轮机叶片颤振的影响[J]. 航空动力学报, 1994, (3): 277- 280. |

| ZHANG Y J , LI K J , TAO D P . Effect of interblade phase angle on blade flutter of steam turbine[J]. Journal of Aerospace Power, 1994, (3): 277- 280. | |

| 7 |

张兴国, 刘锋, 张陈安. 基于CFD技术的叶片颤振分析[J]. 航空计算技术, 2009, 39 (4): 75- 78.

DOI |

|

ZHANG X G , LIU F , ZHANG C A . Flutter computation of turbo machinery blades based on CFD[J]. Aeronautical Computing Technique, 2009, 39 (4): 75- 78.

DOI |

|

| 8 | CARTA F O . Coupled blade-disk-shroud flutter instabilities in turbo-jet engine rotors[J]. Journal of Engineering for Gas Turbines and Power, 2011, 89 (3): 419. |

| 9 | 姜伟, 谢诞梅, 陈畅, 等. 基于时域分析法的汽轮机末级叶片颤振预测及分析[J]. 振动与冲击, 2015, 34 (11): 194- 199. |

| JIANG W , XIE D M , CHEN C , et al. Flutter prediction and analysis for a steam turbine last-stage blade based on time domain analysis method[J]. Journal of Vibration and Shock, 2015, 34 (11): 194- 199. | |

| 10 | 张帅, 高丽敏, 郑天龙, 等. 基于双向流固耦合方法的某风扇特性数值研究[J]. 工程热物理学报, 2017, 38 (8): 1683- 1691. |

| ZHANG S , GAO L M , ZHENG T L , et al. Numerical investigations on characteristic of fan based on two-way fluid-structure interaction approach[J]. Journal of Engineering Thermophysics, 2017, 38 (8): 1683- 1691. | |

| 11 | 郑赟, 杨慧. 跨音速风扇全环叶片颤振特性的流固耦合分析[J]. 北京航空航天大学学报, 2013, 39 (5): 626- 630. |

| ZHENG Y , YANG H . Full assembly fluid/structured flutter analysis of a transonic fan[J]. Journal of Beijing University of Aeronautics and Astronautics, 2013, 39 (5): 626- 630. | |

| 12 | SADEGHI M, LIU F. Coupled fluid-structure simulation for turbomachinary blade rows[EB/OL]. [2021-01-01]. https://arc.aiaa.org/na101/home/literatum/publisher/aiaa/books/content/6.asm/2005/masm05/6.2005-18/staging/6.2005-18.fp.png_v01. |

| 13 | 杜云祥, 徐自力, 焦玉雪, 等. 基于振动时滞法的非零叶间相位角叶片颤振[J]. 航空动力学报, 2020, 35 (8): 189- 198. |

| DU Y X , XU Z L , JIAO Y X , et al. Blades flutter of non-zero inter-blade phase angle based on vibration time-delay method[J]. Journal of Aerospace Power, 2020, 35 (8): 189- 198. | |

| 14 | 周迪, 吕彬彬, 陆志良, 等. 能量法和时域法在叶片颤振计算中的比较研究[J]. 航空计算技术, 2019, 49 (5): 43- 48. |

| ZHOU D , LV B B , LU Z L , et al. Comparative study on energy method and time-domain method for blade flutter predictions[J]. Aeronautical Computing Technique, 2019, 49 (5): 43- 48. | |

| 15 | 李迪, 张晓杰, 王延荣. 压气机转子叶片的抑颤设计[J]. 推进技术, 2020, 41 (9): 207- 216. |

| LI D , ZHANG X J , WANG Y R . Design for flutter suppression of rotor blade in a compressor[J]. Journal of Propulsion Technology, 2020, 41 (9): 207- 216. | |

| 16 | 杨光海. 汽轮机叶片的安全防护[M]. 北京: 机械工业出版社, 1992. |

| YANG G H . Safety protection of steam turbine blade[M]. Beijing: China Machine Press, 1992. |

| [1] | Yanfang LIANG, Shuxuan PENG, Yongjun CUI, Jianchao LUO, Yaonian HE, Linchao BAI, Jinglun FU. Calculation of Heat Transfer Performance of Steam Turbine Shaft Sealing Heater [J]. Power Generation Technology, 2023, 44(6): 817-823. |

| [2] | Zhiyun WANG, Yuzhu ZHAO, Xuedong WANG, Yuanshu ZHANG. Experimental Study on Regulation Characteristics of Intermediate Pressure Cylinder Regulating Valves of Heat Supply Steam Turbine Under Peak Regulating Mechanism [J]. Power Generation Technology, 2022, 43(6): 970-976. |

| [3] | Honghui SHI, Haibo WANG, Rongxiu CAO, Li YAO, Xin YAN. Research on Aerodynamic and Strength Performance of Last Stage in High-Pressure Cylinder of Steam Turbine Under Variable Working Conditions [J]. Power Generation Technology, 2022, 43(6): 959-969. |

| [4] | Qiyao ZUO, Zhen TANG, Huiyong LI, Ying ZHANG, Jiangfeng WANG. Overview on the Current Situation of Steam Turbine Low-Pressure Cylinder Zero-Output Technology Under Background of Power Grid Peak Regulation [J]. Power Generation Technology, 2022, 43(4): 645-654. |

| [5] | Shangnian CHEN, Luping LI, Shihai ZHANG, Minnan OUYANG, Ang FAN, Xiankui WEN. Research Progress of Vibration Fault Diagnosis Technology for Steam Turbine Generator Sets [J]. Power Generation Technology, 2021, 42(4): 489-499. |

| [6] | Yunfeng LIU, Yufeng LI, Jian WANG, Yiliang MA, Chun GUAN. Study on Water Erosion in Deep Peak Shaving of Steam Turbine [J]. Power Generation Technology, 2021, 42(4): 473-479. |

| [7] | Yuting WANG, Yanqi CHEN, Gang XU, Heng CHEN. Study on Structure Optimization of Exhaust Steam Passage of Steam Turbine in Large Coal-fired Power Station [J]. Power Generation Technology, 2021, 42(4): 464-472. |

| [8] | Jing WANG, Jinfu YANG, Liqiang DUAN, Liguo TIAN, Yutian JING, Ming YANG. Optimal Design of Steam Turbine System for Advanced Ultra-supercritical Double Reheat Coal-fired Units [J]. Power Generation Technology, 2021, 42(4): 480-488. |

| [9] | Xiaojun HUANG,Xiangguo DU. Effect of 600 MW Supercritical Steam Turbine Prolonging Running Time of Mixing Valve on Unit Vibration [J]. Power Generation Technology, 2019, 40(2): 175-180. |

| [10] | Yun LUO,Xuelin CHEN,Ruidong LI,Yongjian SU,Yiwei XU,Junkai CHAO,Pengzhu LI,Haibin REN. Prediction Model and Application of Turbine Regulating Stage Pressure Under Variable Conditions [J]. Power Generation Technology, 2019, 40(2): 161-167. |

| [11] | Lihua CAO,Kai ZHOU,Heyong SI. Study on Installing Deflector in Exhaust Hood of Steam Turbine Based on Quadratic Regressive Orthogonal Experiment [J]. Power Generation Technology, 2019, 40(1): 56-60. |

| [12] | Chuanling LIU,Minghui LIU,Zhenjiang CHEN,Ang SONG. Analysis on the Change of Steam Turbine Back Pressure Under Operation of Low Pressure Economizer [J]. Power Generation Technology, 2018, 39(4): 378-381. |

| [13] | Yi LI. Heat Supply System of 2×300MW Units' Circulating Water Waste Heat [J]. Power Generation Technology, 2018, 39(3): 244-248. |

| [14] | WANG Yu, XU Weixuan, GUO Baoren. Vibration Test and Analysis of Dynamic Balancing without Test-mass on Multi-plane for a 350MW Turbo-generator Unit [J]. Power Generation Technology, 2017, 38(6): 53-56. |

| [15] | GUO Shuang, WANG Yu, WANG Yan-dong. Process Analysis of a 600MW Subcritical Air-cooled Unit Speed Up to 3000r/min [J]. Power Generation Technology, 2017, 38(1): 48-50. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||