Power Generation Technology ›› 2023, Vol. 44 ›› Issue (6): 817-823.DOI: 10.12096/j.2096-4528.pgt.23028

• Power Generation and Environmental Protection • Previous Articles Next Articles

Yanfang LIANG1,2, Shuxuan PENG1, Yongjun CUI3, Jianchao LUO3, Yaonian HE3, Linchao BAI1, Jinglun FU1,4,5

Received:2023-03-09

Published:2023-12-31

Online:2023-12-28

Contact:

Jinglun FU

Supported by:CLC Number:

Yanfang LIANG, Shuxuan PENG, Yongjun CUI, Jianchao LUO, Yaonian HE, Linchao BAI, Jinglun FU. Calculation of Heat Transfer Performance of Steam Turbine Shaft Sealing Heater[J]. Power Generation Technology, 2023, 44(6): 817-823.

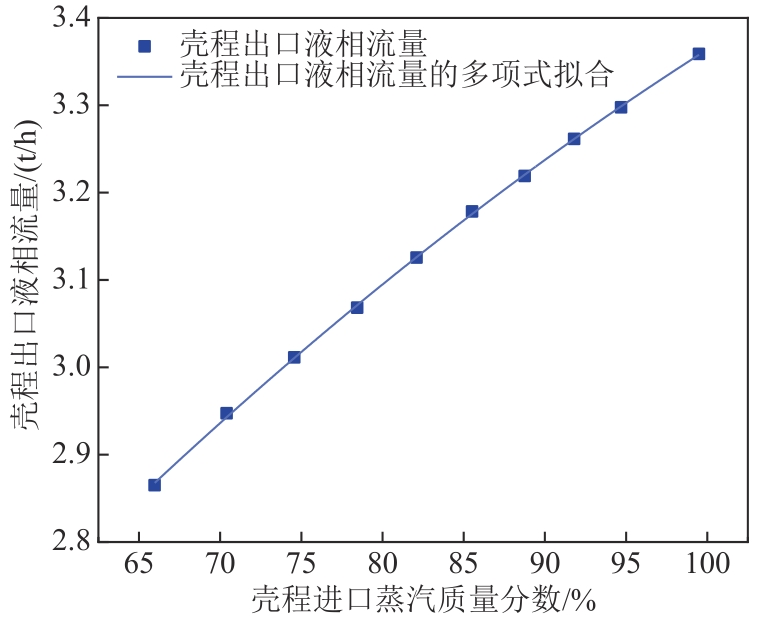

Fig. 6 When the inlet parameters change, the mass fraction of inlet steam on the shell side and the liquid phase flow rate at the outlet of the shell side change

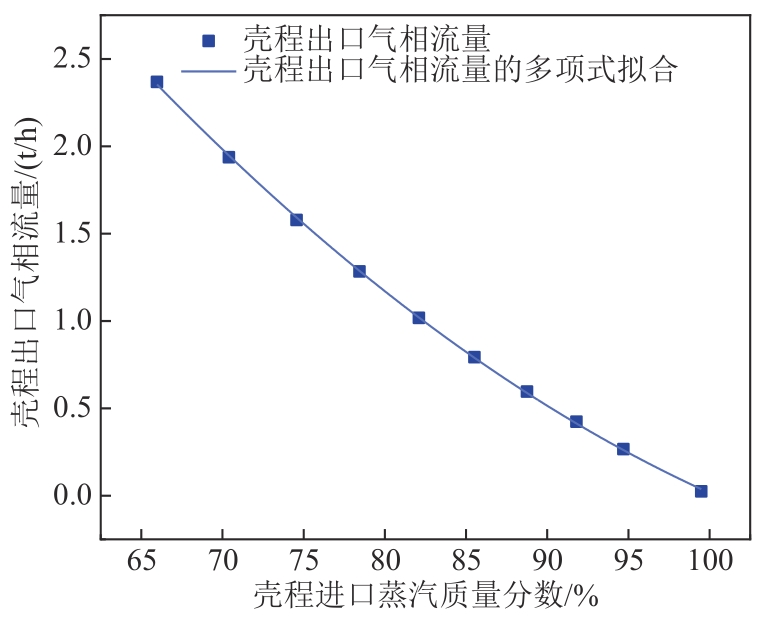

Fig. 7 When the inlet parameters change, the mass fraction of inlet steam on the shell side and the gas phase flow rate at the outlet of the shell side change

| 1 | 唐肄敏 .关于轴封加热器水封缺水现象的思考[J].中国原子能科学研究院年报,2011(1):20-21. |

| TANG Y M . Thoughts on water shortage in water seal of shaft seal heater[J].Annual Report of China Institute of Atomic Energy,2011(1):20-21. | |

| 2 | 王志云,赵玉柱,王学栋,等 .调峰机制下供热汽轮机中压调门调节特性试验研究[J].发电技术,2022,43(6):970-976. doi:10.12096/j.2096-4528.pgt.22080 |

| WANG Z Y, ZHAO Y Z, WANG X D,et al .Experimental study on regulation characteristics of intermediate pressure cylinder regulating valves of heat supply steam turbine under peak regulating mechanism[J].Power Generation Technology,2022,43(6):970-976. doi:10.12096/j.2096-4528.pgt.22080 | |

| 3 | 闫修峰,宗珂,何修年,等 .1 000 MW煤电机组调峰中汽温控制策略研究[J].发电技术,2022,43(3):518-522. doi:10.12096/j.2096-4528.pgt.21024 |

| YAN X F, ZONG K, HE X N,et al .Research on steam temperature control strategy in peak regulation of 1 000 MW coal power unit[J].Power Generation Technology,2022,43(3):518-522. doi:10.12096/j.2096-4528.pgt.21024 | |

| 4 | 柴有国,何晓燕,苏永健,等 .考虑安全环保及补偿的火电机组调峰经济性研究[J].中国电力,2021,54(11):199-205. |

| CAI Y G, HE X Y, SU Y J,et al .Economic research on peak shaving of thermal power units considering safety-environmental protection and compensation[J].Electric Power,2021,54(11):199-205. | |

| 5 | 刘嘉乐,马素霞,马红和,等 .燃气机组热调峰性能及经济性分析[J].中国电力,2021,54(6):104-110. |

| LIU J L, MA S X, MA H H,et al .Analysis on thermal peak shaving and economic performance of gas-fired unit[J].Electric Power,2021,54(6):104-110. | |

| 6 | 王明军 .管壳式换热器的数值模拟与优化设计[D].长沙:中南大学,2011. |

| WANG M J .Numerical simulation and optimal design of shell-and-tube heat exchanger[D].Changsha:Central South University,2011. | |

| 7 | 张之东 .管壳式换热器内部三维流场数值模拟[D].石家庄:河北科技大学,2012. |

| ZHANG Z D .Numerical simulation of three-dimensional flow field in shell-and-tube heat exchanger[D].Shijiazhuang:Hebei University of Science and Technology,2012. | |

| 8 | 张政,张建文 .螺旋内槽管内的层流流动与传热的数值模拟[J].高校化学工程学报,1995,9(2):125-132. |

| ZHANG Z, ZHANG J W .Numerical simulation of laminar fluid flow and heat transfer in spiral internally finned tube[J].Journal of Chemical Engineering of Chinese Universities,1995,9(2):125-132. | |

| 9 | 崔海亭,赵欣 .螺旋槽纹管管内紊流流动与换热数值研究[J].河北科技大学学报,2002,23(4):86-89. doi:10.3969/j.issn.1008-1542.2002.04.020 |

| CUI H T, ZHAO X .Research of numerical simulation of turbulent fluid flow and heat transfer in spirally fluted tubes[J].Journal of Hebei University of Science and Technology,2002,23(4):86-89. doi:10.3969/j.issn.1008-1542.2002.04.020 | |

| 10 | 刘超 .螺旋槽纹管管内流动和换热性能的研究[D].淮南:安徽理工大学,2015. |

| LIU C .Study on flow and heat transfer performance in spiral grooved tube[D].Huainan:Anhui University of Science & Technology,2015. | |

| 11 | 王定标 .纵流壳程换热器数值模拟技术与应用[D].上海:华东理工大学,1999. doi:10.2139/ssrn.4484815 |

| WANG D B .Numerical simulation technology and application of longitudinal flow shell-side heat exchanger[D].Shanghai:East China University of Science and Technology,1999. doi:10.2139/ssrn.4484815 | |

| 12 | 王定标,董其伍,刘敏珊,等 .纵流壳程换热器数值模拟的应用研究[J].郑州工业大学学报,1999(2):18-20. doi:10.3969/j.issn.1671-6833.1999.02.006 |

| WANG D B, DONG Q W, LIU M S,et al .Application study of numerical simulation for longitudinal flow of shell-side heat exchanger[J].Journal of Zhengzhou University of Technology,1999(2):18-20. doi:10.3969/j.issn.1671-6833.1999.02.006 | |

| 13 | 古新,董其伍,王珂 .基于三维实体模型的管壳式换热器壳程流场和温度场数值研究[J].压力容器,2008,25(5):1-5. doi:10.3969/j.issn.1001-4837.2008.05.001 |

| GU X, DONG Q W, WANG K .Numerical study on flow field and temperature field in shellside of shell-and-tube heat exchanger based on 3-D solid model[J].Pressure Vessel Technology,2008,25(5):1-5. doi:10.3969/j.issn.1001-4837.2008.05.001 | |

| 14 | 吴昊鹏 .管壳式换热器壳程流体流动与传热数值模拟研究[J].科技风,2017(19):120. |

| WU H P .Numerical simulation of fluid flow and heat transfer in shell side of shell-and-tube heat exchanger[J].Technology Wind,2017(19):120. | |

| 15 | 邓斌,陶文铨 .管壳式换热器壳侧湍流流动与换热的三维数值模拟[J].化工学报,2004,55(7):1053-1059. doi:10.3321/j.issn:0438-1157.2004.07.006 |

| DENG B, TAO W Q .Three-dimensional numerical simulation of turbulent flow and heat transfer characteristics in shell side of shell-and-tube heat exchangers[J].Journal of Chemical Industry and Engineering,2004,55(7):1053-1059. doi:10.3321/j.issn:0438-1157.2004.07.006 | |

| 16 | 吴金星,魏新利,董其伍,等 .杆支撑换热器壳程的单元流道模型及流场分布[J].化工进展,2007,26(1):69-72. doi:10.3321/j.issn:1000-6613.2007.01.015 |

| WU J X, WEI X L, DONG Q W,et al .Unit duct model and flow field distribution in shell side of rod baffle heat exchanger[J].Chemical Industry and Engineering Progress,2007,26(1):69-72. doi:10.3321/j.issn:1000-6613.2007.01.015 | |

| 17 | 张亮,原亚东,孙志强,等 .波纹管对管壳式换热器内流体传热及流动特性的影响[J].热能动力工程,2019,34(4):73-78. |

| ZHANG L, YUAN Y D, SUN Z Q,et al .Effects of corrugated tube on heat transfer and flow characteristics of fluid in shell heat exchanger[J].Journal of Engineering for Thermal Energy and Power,2019,34(4):73-78. | |

| 18 | 王争,董敏 .基于Fluent的管壳式换热器进气管组件结构优化数值模拟[J].现代信息科技,2022(20):111-115. |

| WANG Z, DONG M .Numerical simulation of inlet pipe assembly structure optimization of shell and tube heat exchanger based on fluent[J].Modern Informationn Technology,2022(20):111-115. | |

| 19 | 何超,瞿莹,王华玲,等 .管壳式换热器壳程流体流动与传热的数值模拟研究[J].装备制造技术,2022(3):43-45. doi:10.3969/j.issn.1672-545X.2022.03.011 |

| HE C, QU Y, WANG H L,et al .Numerical simulation of fluid flow and heat transfer in shell side of shell-and-tube heat exchanger[J].Equipment Manufacturing Technology,2022(3):43-45. doi:10.3969/j.issn.1672-545X.2022.03.011 | |

| 20 | 沈维道,童钧耕 .工程热力学[M].5版.北京:高等教育出版社,2016. |

| SHEN W D, TONG J G .Engineering thermodynamics[M]. 5th Edition.Beijing:Higher Education Press,2016. | |

| 21 | 陶文铨 .传热学[M].5版.北京:高等教育出版社,2019. doi:10.2991/icsshe-19.2019.79 |

| TAO W Q .Heat transfer[M].5th Edition.Beijing:Higher Education Press,2019. doi:10.2991/icsshe-19.2019.79 |

| [1] | Zhiyun WANG, Yuzhu ZHAO, Xuedong WANG, Yuanshu ZHANG. Experimental Study on Regulation Characteristics of Intermediate Pressure Cylinder Regulating Valves of Heat Supply Steam Turbine Under Peak Regulating Mechanism [J]. Power Generation Technology, 2022, 43(6): 970-976. |

| [2] | Honghui SHI, Haibo WANG, Rongxiu CAO, Li YAO, Xin YAN. Research on Aerodynamic and Strength Performance of Last Stage in High-Pressure Cylinder of Steam Turbine Under Variable Working Conditions [J]. Power Generation Technology, 2022, 43(6): 959-969. |

| [3] | Qiyao ZUO, Zhen TANG, Huiyong LI, Ying ZHANG, Jiangfeng WANG. Overview on the Current Situation of Steam Turbine Low-Pressure Cylinder Zero-Output Technology Under Background of Power Grid Peak Regulation [J]. Power Generation Technology, 2022, 43(4): 645-654. |

| [4] | Changchun LIU, Chun GUAN, Kuijun GUO, Yufeng LI, Yiliang MA. Flutter Prediction Method for Long Blade of Steam Turbine [J]. Power Generation Technology, 2021, 42(4): 500-508. |

| [5] | Shangnian CHEN, Luping LI, Shihai ZHANG, Minnan OUYANG, Ang FAN, Xiankui WEN. Research Progress of Vibration Fault Diagnosis Technology for Steam Turbine Generator Sets [J]. Power Generation Technology, 2021, 42(4): 489-499. |

| [6] | Yunfeng LIU, Yufeng LI, Jian WANG, Yiliang MA, Chun GUAN. Study on Water Erosion in Deep Peak Shaving of Steam Turbine [J]. Power Generation Technology, 2021, 42(4): 473-479. |

| [7] | Yuting WANG, Yanqi CHEN, Gang XU, Heng CHEN. Study on Structure Optimization of Exhaust Steam Passage of Steam Turbine in Large Coal-fired Power Station [J]. Power Generation Technology, 2021, 42(4): 464-472. |

| [8] | Jing WANG, Jinfu YANG, Liqiang DUAN, Liguo TIAN, Yutian JING, Ming YANG. Optimal Design of Steam Turbine System for Advanced Ultra-supercritical Double Reheat Coal-fired Units [J]. Power Generation Technology, 2021, 42(4): 480-488. |

| [9] | Xiaojun HUANG,Xiangguo DU. Effect of 600 MW Supercritical Steam Turbine Prolonging Running Time of Mixing Valve on Unit Vibration [J]. Power Generation Technology, 2019, 40(2): 175-180. |

| [10] | Yun LUO,Xuelin CHEN,Ruidong LI,Yongjian SU,Yiwei XU,Junkai CHAO,Pengzhu LI,Haibin REN. Prediction Model and Application of Turbine Regulating Stage Pressure Under Variable Conditions [J]. Power Generation Technology, 2019, 40(2): 161-167. |

| [11] | Lihua CAO,Kai ZHOU,Heyong SI. Study on Installing Deflector in Exhaust Hood of Steam Turbine Based on Quadratic Regressive Orthogonal Experiment [J]. Power Generation Technology, 2019, 40(1): 56-60. |

| [12] | Chuanling LIU,Minghui LIU,Zhenjiang CHEN,Ang SONG. Analysis on the Change of Steam Turbine Back Pressure Under Operation of Low Pressure Economizer [J]. Power Generation Technology, 2018, 39(4): 378-381. |

| [13] | Yi LI. Heat Supply System of 2×300MW Units' Circulating Water Waste Heat [J]. Power Generation Technology, 2018, 39(3): 244-248. |

| [14] | WANG Yu, XU Weixuan, GUO Baoren. Vibration Test and Analysis of Dynamic Balancing without Test-mass on Multi-plane for a 350MW Turbo-generator Unit [J]. Power Generation Technology, 2017, 38(6): 53-56. |

| [15] | GUO Shuang, WANG Yu, WANG Yan-dong. Process Analysis of a 600MW Subcritical Air-cooled Unit Speed Up to 3000r/min [J]. Power Generation Technology, 2017, 38(1): 48-50. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||