Power Generation Technology ›› 2024, Vol. 45 ›› Issue (6): 1087-1094.DOI: 10.12096/j.2096-4528.pgt.23176

• Power Generation and Environmental Protection • Previous Articles

Zhuo LIU, Donglin CHEN, Shuqi WANG, Yijiang YANG, Youyang YAN, Zhan YANG

Received:2024-06-20

Revised:2024-09-25

Published:2024-12-31

Online:2024-12-30

Contact:

Donglin CHEN

Supported by:CLC Number:

Zhuo LIU, Donglin CHEN, Shuqi WANG, Yijiang YANG, Youyang YAN, Zhan YANG. Optimization Method of Flow Field for Alleviating Clogging of Mist Eliminator in Desulfurization Tower[J]. Power Generation Technology, 2024, 45(6): 1087-1094.

| 三维模型 | 横向定位尺寸/m | 纵向定位尺寸/m | 横向定形尺寸/m | 纵向定形尺寸/m | 半径/m | 角度定位尺寸/(°) |

|---|---|---|---|---|---|---|

| L形进口烟道 | — | |||||

| Z形脱硫塔 | — |

Tab. 1 Shaping and positioning dimensions of guide plate

| 三维模型 | 横向定位尺寸/m | 纵向定位尺寸/m | 横向定形尺寸/m | 纵向定形尺寸/m | 半径/m | 角度定位尺寸/(°) |

|---|---|---|---|---|---|---|

| L形进口烟道 | — | |||||

| Z形脱硫塔 | — |

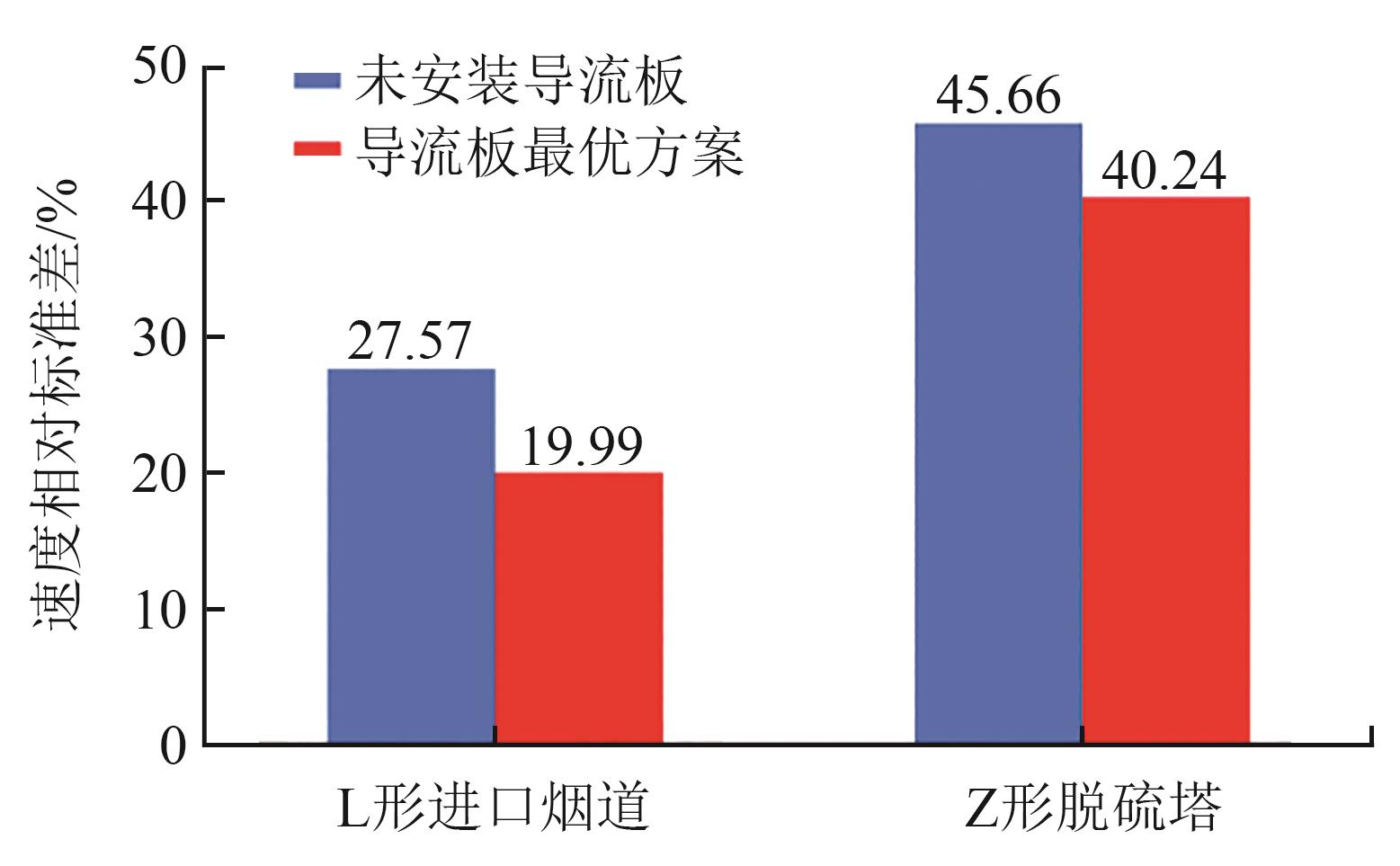

Fig. 10 Relative standard deviation of velocity of exit section of L-shaped inlet flue and entrance section of mist eliminator in Z-shaped desulphurization tower

| 1 | 夏忠林,陈文通,许书峤,等 .火电厂烟塔合一技术应用现状与现存问题分析[J].发电技术,2024,45(4):590-599. |

| XIA Z L, CHEN W T, XU S Q,et al .Application status and existing problem analysis of the natural draft cooling towers with flue gas injection technology in thermal power plants[J].Power Generation Technology,2024,45(4):590-599. | |

| 2 | 张双平,陈伟雄,贾西部,等 .脱硫塔除雾器安装高度对烟气携液量影响的模拟研究[J].发电技术,2021,42(2):247-253. doi:10.12096/j.2096-4528.pgt.20039 |

| ZHANG S P, CHEN W X, JIA X B,et al .Simulation study on influence of installation height of mist eliminator on liquid holdup of flue gas in desulfurization tower[J].Power Generation Technology,2021,42(2):247-253. doi:10.12096/j.2096-4528.pgt.20039 | |

| 3 | 禾志强,祁利明,马青树 .石灰石-石膏法脱硫系统除雾器堵塞研究[J].锅炉技术,2010,41(1):77-80. |

| HE Z Q, QI L M, MA Q S .The study of demister blocking in limestone-gypsum desulfurization technology[J].Boiler Technology,2010,41(1):77-80. | |

| 4 | 潘超群 .石灰石-石膏湿法烟气脱硫除雾器堵塞分析与对策[J].能源环境保护,2015,29(4):30-31. |

| PAN C Q .Analysis and countermeasures of clogging in limestone-gypsum wet flue gas desulfurization mist eliminator[J].Energy Environmental Protection,2015,29(4):30-31. | |

| 5 | 马晓丽,张襄平 .无GGH湿法脱硫系统除雾器堵塞原因及防堵建议[J].电力科技与环保,2012,28(2):35-36. |

| MA X L, ZHANG X P .Analysis of causes of mist eliminators blockage in wet FGD systems without GGH and its countermeasures[J].Electric Power Technology and Environmental Protection,2012,28(2):35-36. | |

| 6 | 纪小春 .折流板式除雾器的结垢与控制措施[J].黑龙江电力,2012,34(2):131-134. |

| JI X C .Scaling and its control measure of chevron mist eliminator[J].Heilongjiang Electric Power,2012,34(2):131-134. | |

| 7 | 郭东明 .脱硫工程技术与设备[M].北京:化学工业出版社,2019:165-170. |

| GUO D M .Desulfurization engineering technology and equipment[M].Beijing:Chemical Industry Press,2019:165-170. | |

| 8 | 林瑜,陈德珍,尹丽洁 .喷淋层组合方式对大型脱硫塔内流动和热湿交换过程影响的数值模拟[J].中南大学学报(自然科学版),2017,48(10):2572-2582. |

| LIN Y, CHEN D Z, YIN L J .Numerical simulation of impact of spraying layers scheme on gas-liquid two phases flow,heat and mass transfer in large scale desulphurization absorption tower[J].Journal of Central South University (Science and Technology),2017,48(10):2572-2582. | |

| 9 | 王霄,闵健,高正明,等 .脱硫吸收塔除雾器性能的实验研究和数值模拟[J].环境工程学报,2008,2(11):1529-1534. |

| WANG X, MIN J, GAO Z M,et al .Experimental study and numerical simulation of characteristics of demister of absorbing tower in desulfurization system[J].Chinese Journal of Environmental Engineering,2008,2(11):1529-1534. | |

| 10 | 尤良洲,杜振,江建平,等 .管束式除尘除雾器在脱硫串塔系统中的应用及性能评价[J].中国电力,2017,50(12):173-177. |

| YOU L Z, DU Z, JIANG J P,et al .The application and performance evalution of bundle precipitator in series absorpti tower of desnifurization system[J].Electric Power,2017,50(12):173-177. | |

| 11 | 邱桂芝,张志刚,宋寅,等 .管束式除雾器结构优化数值模拟及高效除雾器研制[J].中国电力,2018,51(5):134-140. |

| QIU G Z, ZHANG Z G, SONG Y .Numerical simulation on tube bundle demister and development of high efficiency demister[J].Electric Power,2018,51(5):134-140. | |

| 12 | 李文鼎,高惠华,蔡文丰 .石灰石-石膏湿法脱硫吸收塔结垢分析及预防措施[J].发电技术,2019,40(1):51-55. |

| LI W D, GAO H H, CAI W F .Scaling analysis and preventive measures of limestone-gypsum wet flue gas desulfurization[J].Power Generation Technology,2019,40 (1):51-55. | |

| 13 | AZZOPARDI J B, SANAULLAH S K .Re-entrainment in wave-plate mist eliminators[J].Chemical Engineering Science,2002,57(17):3557-3563. doi:10.1016/s0009-2509(02)00270-1 |

| 14 | MAO F, TIAN R F, CHEN Y X,et al .Re-entrainment in and optimization of a vane mist eliminator[J].Annals of Nuclear Energy,2018,120(11):656-665. doi:10.1016/j.anucene.2018.06.011 |

| 15 | 张维蔚,吕凡,庄晓凤,等 .弯管二次流及电厂锅炉均流技术的研究进展[J].热能动力工程,2014,29(6):603-609. |

| ZHANG W W, LV F, ZHUANG X F,et al .Research progress of secondary flow in bent pipe and flow sharing technology in power plant boiler[J].Thermal Power Engineering,2014,29(6):603-609. | |

| 16 | 田森浩,向勇林,陈冬林,等 .内置导流板的湿法脱硫塔数值模拟优化及应用[J].动力工程学报,2021,41(9):766-772. |

| TIAN S H, XIANG Y L, CHEN D L,et al .Numerical simulation optimization and application of wet desulfurization tower with inner guide plate[J].Journal of Chinese Society of Power Engineering,2021,41(9):766-772. | |

| 17 | 陈慧敏,李香龙,刘秀兰,等 .大功率充电连接器相变冷却换热特性研究[J].电力科学与技术学报,2024,39(1):201-207. |

| CHEN H M, LI X L, LIU X L,et al .Study of phase change cooling heat transfer characteristics of high power charging connectors[J].Journal of Electric Power Science and Technology,2024,39(1):201-207. | |

| 18 | 李子新,王硕,赵隆,等 .多参数影响的导线热稳监测及动态增容研究[J].智慧电力,2022,50(12):100-106. |

| LI Z X, WANG S, ZHAO L,et al .Thermal stability monitoring of conductor and dynamic line rating considering effects of multiple parameters[J].Smart Power,2022,50(12):100-106. | |

| 19 | 张育平,刘俊,王沣浩,等 .中深层U型对接井取热能力影响因素显著性分析[J].可再生能源,2022,40(11):1473-1480. |

| ZHANG Y P, LIU J, WANG F H,et al .Significance analysis on the influence factors of thermal extraction capacity of medium-deep U-shaped butted well[J].Renewable Energy Resources,2022,40(11):1473-1480. | |

| 20 | 郭胜江,吴广庆,陈国邦 .适用于回流区流体力学模拟计算的三种高雷诺数湍流模型的比较[J].制冷学报,2005,26(3):26-29. |

| GUO S J, WU G Q, CHEN G B .Comparison of three high-reynolds-number models in recirculation zones for simulation of computational fluid dynamics[J].Journal of Refrigeration,2005,26(3):26-29. | |

| 21 | 张井龙,王尊策,徐艳 .壁面处理对壁面旋转旋流器流动模拟的影响分析[J].数学的实践与认识,2022,52(10):142-146. |

| ZHANG J L, WANG Z C, XU Y .Analysis of effect of near-wall treatments on numerical computation of rotating hydrocyclone[J].Journal of Mathematics in Practice and Theory,2022,52(10):142-146. | |

| 22 | 王新光,毛枚良,何琨,等 .壁面函数在超声速湍流模拟中的应用[J].航空学报,2022,43(9):290-298. |

| WANG X G, MAO M L, HE K,et al .Application of wall function to supersonic turbulence simulation[J].Acta Aeronautica et Astronautica Sinica,2022,43(9):290-298. | |

| 23 | 张涛,朱晓军,彭飞,等 .近壁面处理对湍流数值计算的影响分析[J].海军工程大学学报,2013,25(6):104-108. |

| ZHANG T, ZHU X J, PENG F,et al .Analysis of effect of near-wall treatments on numerical computation of turbulent flow[J].Journal of Naval University of Engineering,2013,25(6):104-108. | |

| 24 | 杨丁 .湿法烟气脱硫吸收塔阻力特性实验研究[J].中国环保产业,2018(5):31-36. |

| YANG D .Experimental study on absorber resistance characteristic of WFGD[J].China Environmental Protection Industry,2018(5):31-36. | |

| 25 | 刘文斌,李璐璐,李晓金,等 .脱硫湿烟气喷淋冷凝过程中的参数优化研究[J].发电技术,2023,44(1):107-114. doi:10.12096/j.2096-4528.pgt.21064 |

| LIU W B, LI L L, LI X J,et al .Study on parameter optimization of desulfurized wet flue gas in spray condensation process[J].Power Generation Technology,2023,44(1):107-114. doi:10.12096/j.2096-4528.pgt.21064 | |

| 26 | 蒋惠梦,谷小兵,余苏玲,等 .湿法烟气脱硫喷淋塔的阻力特性研究[J].环境保护科学,2017,43(3):85-90. |

| JIANG H M, GU X B, YU S L,et al .Research of resistance characteristics of wet flue gas desulfurization spraying scrubber[J].Environmental Protection Science,2017,43(3):85-90. | |

| 27 | 冉景煜,邓庆波,牛俊天,等 .湿法脱硫塔内流场均匀性影响因素及其评价方法[J].动力工程学报,2020,40(10):825-831. |

| RAN J Y, DENG Q B, NIU J T,et al .Influence factors and evaluation method on the uniformity of flow field in a WFGD tower[J].Journal of Chinese Society of Power Engineering,2020,40(10):825-831. |

| [1] | Mingyang ZHAO, Linlin YIN, Wentao WEI, Yun CHEN, Richen LIU, Jun LI. Impact of Falling Blocks of High Pressure Turbine Rotor Blades With Squealer Tip on the Aerodynamic Performance and Vibration Characteristics [J]. Power Generation Technology, 2024, 45(5): 856-867. |

| [2] | Gengsheng LIU, Jianyong ZHANG, Quan SUN, Shan CAO, Anqi GONG, Lin JIANG, Yongsheng ZHANG. Study on the Removal of Heavy Metals From Wastewater by Ultra High Lime With Aluminum Precipitation Coupling Activated Carbon Adsorption in 300 MW Coal-Fired Units [J]. Power Generation Technology, 2024, 45(5): 959-968. |

| [3] | Zhonglin XIA, Wentong CHEN, Shuqiao XU, Zhongsheng WU, Qiang XIE, Shuangchen MA, Jingxiang MA. Application Status and Existing Problem Analysis of the Natural Draft Cooling Towers With Flue Gas Injection Technology in Thermal Power Plants [J]. Power Generation Technology, 2024, 45(4): 590-599. |

| [4] | Yong DING. Research on Deep Peak Shaving Performance of 1 000 MW Ultra-Supercritical Coal-Fired Boiler [J]. Power Generation Technology, 2024, 45(3): 382-391. |

| [5] | Nan TU, Jiachen LIU, Jing XU, Jiabin FANG, Yanhua MA. Performance Analysis of Heat Storage and Release Process for a Shell-and-Tube Phase Change Heat Exchanger [J]. Power Generation Technology, 2024, 45(3): 508-516. |

| [6] | Xue LIU, Guodong LI, Ruiying ZHANG, Yichen HOU, Lei CHEN, Lijun YANG. Research on Axial Flow Fan Models of Air Cooling Island in Power Plant [J]. Power Generation Technology, 2024, 45(3): 545-557. |

| [7] | Sihai ZHANG, Chaoran LI, Guangliang WAN, Yinxue LIU, Hainan XU, Zhong HUANG, Hairui YANG. Deep Peak Shaving Technology for 330 MW Circulating Fluidized Bed Boiler [J]. Power Generation Technology, 2024, 45(2): 199-206. |

| [8] | Qigang DENG, Zhuo LÜ, You SHI, Jiayi LU, Xu ZHOU, Aoyu WANG, Dong YANG. Safety Calculation and Analysis of Water Wall for a 700 MW Ultra-Supercritical Circulating Fluidized Bed Boiler Without External Bed After Power Failure [J]. Power Generation Technology, 2024, 45(2): 240-249. |

| [9] | Siqi GONG, Zaipeng YUN, Ming XU, Le AO, Chufu LI, Kai HUANG, Chen SUN. Numerical Simulation of Solid Oxide Fuel Cell Tail Gas Catalytic Combustion Based on Three-Way Catalyst [J]. Power Generation Technology, 2024, 45(2): 331-340. |

| [10] | Xiaohe XIONG, Falin CHEN, Renhui RUAN, Houzhang TAN, Yansen LI. Experiment on Multi-Component Synchronous Test of Reducing Atmosphere Adjacent to Water Wall of High Temperature Corrosion Boiler [J]. Power Generation Technology, 2023, 44(6): 800-808. |

| [11] | Zhongrong LIANG, Maowei LAN, Guo ZHENG, Rongqiang HE, Keyang QU, Yunhua GAN. Study on Multi-Objective Optimization of High-Efficiency and Low-NO x Emissions of Power Station Boilers Based on Least Squares Support Vector Machines [J]. Power Generation Technology, 2023, 44(6): 809-816. |

| [12] | Yang YANG, Yaoqiang LI, Jinqi ZHANG. Design of Dome Structure for A Lean Premixed Swirled Combustor of Gas Turbine Based on the Numerical Method [J]. Power Generation Technology, 2023, 44(5): 712-721. |

| [13] | Lin WANG. Research on Closed Cycle Pipe Blowing Technology of 5 MW Supercritical Carbon Dioxide Unit Boiler [J]. Power Generation Technology, 2023, 44(5): 731-737. |

| [14] | Lifeng ZHANG, Jing LI, Zhi WANG. Reconstruction of Temperature Distribution by Acoustic Tomography Based on Principal Component Analysis and Deep Neural Network [J]. Power Generation Technology, 2023, 44(3): 399-406. |

| [15] | Quanbin ZHANG, Qiongfang ZHOU. Research on the Development Path of China’s Thermal Power Generation Technology Based on the Goal of “Carbon Peak and Carbon Neutralization” [J]. Power Generation Technology, 2023, 44(2): 143-154. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||