发电技术 ›› 2024, Vol. 45 ›› Issue (2): 240-249.DOI: 10.12096/j.2096-4528.pgt.23134

邓启刚1,2, 吕卓1,2, 石友1,2, 鲁佳易1,2, 周旭1,2, 王奥宇3, 杨冬3

收稿日期:2023-10-27

出版日期:2024-04-30

发布日期:2024-04-29

通讯作者:

石友

作者简介:基金资助:Qigang DENG1,2, Zhuo LÜ1,2, You SHI1,2, Jiayi LU1,2, Xu ZHOU1,2, Aoyu WANG3, Dong YANG3

Received:2023-10-27

Published:2024-04-30

Online:2024-04-29

Contact:

You SHI

Supported by:摘要:

通过对某660 MW电厂失电事故过程中烟气温度、蒸汽温度及工质流量的变化规律进行分析,得到了炉膛密相区、过渡区及稀相区热负荷随时间的变化规律。在此基础上,以某700 MW超超临界循环流化床(circulating fluidized bed,CFB)锅炉为对象,建立了失电事故发生后水冷壁内的流动传热计算模型,开发了以Fortran语言为基础的水冷壁内瞬态特性计算程序。分别对密相区、过渡区及稀相区进行分析,通过计算得到了失电后的水冷壁壁温及出口工质温度等热力参数的变化规律。计算结果表明:失电后水冷壁密相区出口的最高壁温为558.6 ℃,稀相区出口的最高壁温为579.6 ℃,不需要配备紧急补水泵来保证失电后水冷壁的安全。研究结果可为电厂处理超超临界CFB锅炉失电事故提供指导。

中图分类号:

邓启刚, 吕卓, 石友, 鲁佳易, 周旭, 王奥宇, 杨冬. 不带外置床的700 MW超超临界循环流化床锅炉失电后水冷壁安全计算分析[J]. 发电技术, 2024, 45(2): 240-249.

Qigang DENG, Zhuo LÜ, You SHI, Jiayi LU, Xu ZHOU, Aoyu WANG, Dong YANG. Safety Calculation and Analysis of Water Wall for a 700 MW Ultra-Supercritical Circulating Fluidized Bed Boiler Without External Bed After Power Failure[J]. Power Generation Technology, 2024, 45(2): 240-249.

| 参数 | 数值(100% BMCR负荷下) |

|---|---|

| 水冷壁入口流量/(t∙h-1) | 1 832.64 |

| 水冷壁出口压力/MPa | 31.756 |

| 水冷壁出口温度/℃ | 430 |

| 省煤器入口流量/(t∙h-1) | 1 925 |

| 给水压力/MPa | 32.25 |

| 给水温度/℃ | 309.8 |

表1 锅炉主要设计参数

Tab. 1 Main design parameters of boiler

| 参数 | 数值(100% BMCR负荷下) |

|---|---|

| 水冷壁入口流量/(t∙h-1) | 1 832.64 |

| 水冷壁出口压力/MPa | 31.756 |

| 水冷壁出口温度/℃ | 430 |

| 省煤器入口流量/(t∙h-1) | 1 925 |

| 给水压力/MPa | 32.25 |

| 给水温度/℃ | 309.8 |

| 参数 | 数值 |

|---|---|

| 下炉膛水冷壁厚度/mm | 31.8 |

| 下炉膛水冷壁外径/mm | 6.5 |

| 上炉膛水冷壁厚度/mm | 33.4 |

| 上炉膛水冷壁外径/mm | 7 |

| 下炉膛耐磨材料厚度/mm | 47.5 |

| 下炉膛耐磨材料导热系数/[W/(m⋅K)] | 3 |

| 水冷壁导热系数/[W/(m⋅K)] | 22.6 |

| 浇注料区高度/m | 11.5 |

表2 水冷壁管结构参数

Tab. 2 Structural parameters of water wall tube

| 参数 | 数值 |

|---|---|

| 下炉膛水冷壁厚度/mm | 31.8 |

| 下炉膛水冷壁外径/mm | 6.5 |

| 上炉膛水冷壁厚度/mm | 33.4 |

| 上炉膛水冷壁外径/mm | 7 |

| 下炉膛耐磨材料厚度/mm | 47.5 |

| 下炉膛耐磨材料导热系数/[W/(m⋅K)] | 3 |

| 水冷壁导热系数/[W/(m⋅K)] | 22.6 |

| 浇注料区高度/m | 11.5 |

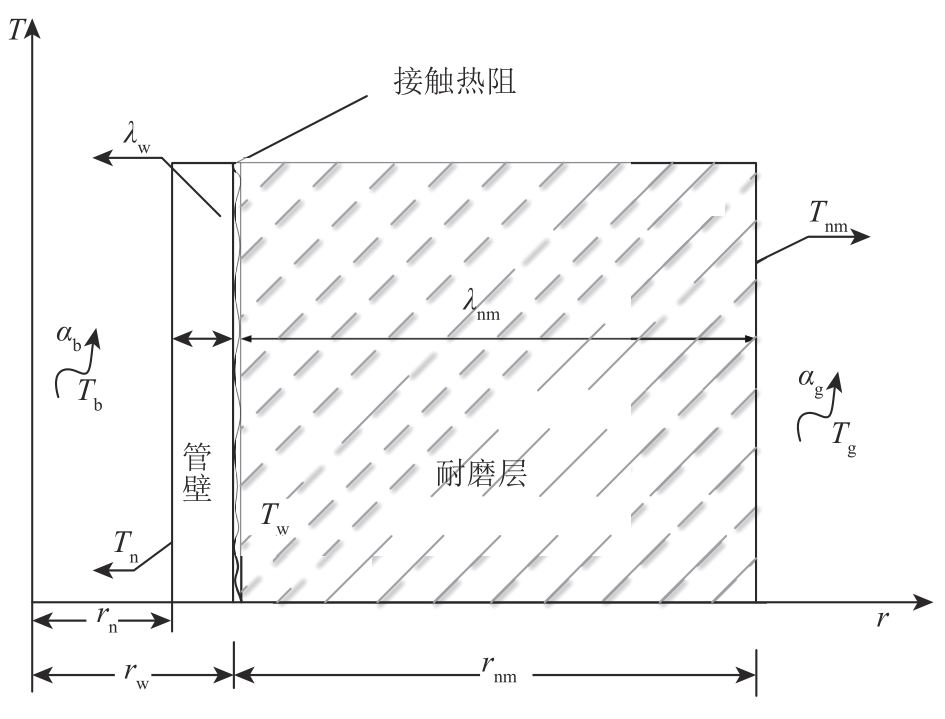

图3 锅炉密相区耐火材料传热过程示意图Tnm为耐磨层外壁温度,K;Tg为烟气侧温度,K;λw为壁面导热系数,W/(m2⋅K);λnm为耐磨材料导热系数,W/(m2⋅K);Tw为管壁与耐磨层交界面温度,K;αb为工质对流换热系数,W/(m2⋅K);rn、rw分别为水冷壁内、外径,mm;rnm为耐磨层厚度,mm。

Fig. 3 Schematic diagram of heat transfer process of refractory materials in dense phase zone of boiler

| 时间/s | 省煤器进口工质流量/(t⋅h-1) | 省煤器进口焓值/(kJ⋅kg-1) |

|---|---|---|

| 0 | 1 925.00 | 1 377.82 |

| 30 | 1 925.00 | 1 377.82 |

| 40 | 1 478.57 | 1 377.82 |

| 50 | 973.50 | 1 377.82 |

| 60 | 448.45 | 1 377.82 |

| 70 | 0 | 0 |

| 3 000 | 0 | 0 |

表3 失电后省煤器进口工质参数变化

Tab. 3 Inlet parameter variation of working fluid for economizer after power failure

| 时间/s | 省煤器进口工质流量/(t⋅h-1) | 省煤器进口焓值/(kJ⋅kg-1) |

|---|---|---|

| 0 | 1 925.00 | 1 377.82 |

| 30 | 1 925.00 | 1 377.82 |

| 40 | 1 478.57 | 1 377.82 |

| 50 | 973.50 | 1 377.82 |

| 60 | 448.45 | 1 377.82 |

| 70 | 0 | 0 |

| 3 000 | 0 | 0 |

| 1 | 董洁,乔建强 .“双碳”目标下先进煤炭清洁利用发电技术研究综述[J].中国电力,2022,55(8):202-212. |

| DONG J, QIAO J Q .A review on advanced clean coal power generation technology under “carbon peaking and carbon neutrality” goal[J].Electric Power,2022,55(8):202-212. | |

| 2 | 王洪健,王海洋,孔皓,等 .135 MW循环流化床锅炉纯燃准东煤改造策略与运行技术研究[J].发电技术,2022,43(6):918-926. doi:10.12096/j.2096-4528.pgt.21107 |

| WANG H J, WANG H Y, KONG H,et al .Retrofitting strategy and operating technology of pure burning Zhundong coal in a 135 MW circulating fluidized bed boiler[J].Power Generation Technology,2022,43(6):918-926. doi:10.12096/j.2096-4528.pgt.21107 | |

| 3 | 吕俊复,周托,张扬,等 .碳中和目标下循环流化床锅炉技术的展望[J].动力工程学报,2022,42(11):1005-1012. doi:10.19805/j.cnki.jcspe.2022.11.002 |

| LV J F, ZHOU T, ZHANG Y,et al .Prospect of the circulating fluidized bed boiler technology for the goal of carbon neutralization[J].Journal of Chinese Society of Power Engineering,2022,42(11):1005-1012. doi:10.19805/j.cnki.jcspe.2022.11.002 | |

| 4 | LI D, KE X, ZHANG M,et al .A comprehensive mass balance model of a 550 MWe ultra-supercritical CFB boiler with internal circulation[J].Energy,2020,206:117941. doi:10.1016/j.energy.2020.117941 |

| 5 | 胡仙楠,邓博宇,刘欢鹏,等 .循环流化床锅炉负荷快速调节技术现状及发展趋势[J].洁净煤技术,2023,29(6):11-23. |

| HU X N, DENG B Y, LIU H P,et al .Status and development trend of rapid load regulation technology for circulating fluidized bed boiler[J].Clean Coal Technology,2023,29(6):11-23. | |

| 6 | 张少强,陈露,刘子易,等 .大型燃煤锅炉深度调峰关键问题探讨[J].南方能源建设,2022,9(3):16-28. doi:10.16516/j.gedi.issn2095-8676.2022.03.003 |

| ZHANG S Q, CHEN L, LIU Z Y,et al .Discussion on key problems of depth peak adjustment for large coal-fired boilers[J].Southern Energy Construction,2022,9(3):16-28. doi:10.16516/j.gedi.issn2095-8676.2022.03.003 | |

| 7 | 宋畅,吕俊复,杨海瑞,等 .超临界及超超临界循环流化床锅炉技术研究与应用[J].中国电机工程学报,2018,38(2):338-347. |

| SONG C, LV J F, YANG H R,et al .Research and application of supercritical and ultra-supercritiacl circulating fluidized bed boiler technology[J].Proceesings of the CSEE,2018,38(2):338-347. | |

| 8 | 王思洋,王文毓,沈植,等 .高效宽负荷率超超临界锅炉垂直管圈水冷壁在低质量流速下的传热特性[J].动力工程学报,2017,37(2):85-90. doi:10.3969/j.issn.1674-7607.2017.02.001 |

| WANG S Y, WANG W Y, SHEN Z,et al .Heat-transfer performance of vertical water wall in an ultra-supercritical pressure boiler with high efficiency and wide regulation load at low mass flux[J].Journal of Chinese Society of Power Engineering,2017,37(2):85-90. doi:10.3969/j.issn.1674-7607.2017.02.001 | |

| 9 | 许霖杰,程乐鸣,季杰强,等 .超/超临界循环流化床锅炉整体数值模型[J].中国电机工程学报,2018,38(2):348-355. |

| XU L J, CHENG L M, JI J Q,et al .Integrated numerical model for ultra/supercritical CFB boilers[J].Proceesings of the CSEE,2018,38(2):348-355. | |

| 10 | ZHANG Z, ZHAO C R, YANG X T,et al .Influences of tube wall on the heat transfer and flow instability of various supercritical pressure fluids in a vertical tube[J].Applied Thermal Engineering,2019,147:242-250. doi:10.1016/j.applthermaleng.2018.10.024 |

| 11 | DENG B Y, ZHOU T, ZHANG S M,et al .Safety analysis on the heating surfaces in the 660 MW ultra-supercritical CFB boiler under sudden electricity failure[J].Energies,2022,15(21):7982. doi:10.3390/en15217982 |

| 12 | 李耀德,董乐,李娟,等 .600 MW超超临界循环流化床锅炉水冷壁传热特性研究[J].热能动力工程,2021,36(6):86-93. |

| LI Y D, DONG L, LI J,et al .Study on water wall heat transfer characteristics of 600 MW ultra-supercritical circulating fluidized bed boiler[J].Journal of Engineering for Thermal Energy and Power,2021,36(6):86-93. | |

| 13 | 王文毓,李耀德,赵云杰,等 .超超临界循环流化床锅炉内螺纹管水冷壁流动传热特性试验研究[J].中国电机工程学报,2018,38(2):373-382. |

| WANG W Y, LI Y D, ZHAO Y J,et al .The experimental investigation on flow and heat transfer characteristics of the rifles water wall tube of an ultra-supercritical CFB boiler[J].Proceesings of the CSEE,2018,38(2):373-382. | |

| 14 | SHEN Z, YANG D, XIE H Y,et al .Flow and heat transfer characteristics of high-pressure water flowing in a vertical upward smooth tube at low mass flux conditions[J].Applied Thermal Engineering,2016,102:391-401. doi:10.1016/j.applthermaleng.2016.03.150 |

| 15 | SHEN Z, YANG D, MAO K Y,et al .Heat transfer characteristics of water flowing in a vertical upward rifled tube with low mass flux[J].Experimental Thermal and Fluid Science,2016,70:341-353. doi:10.1016/j.expthermflusci.2015.09.021 |

| 16 | 李舟航,张大龙,吴玉新,等 .垂直上升光管内超临界水的传热恶化分析和判据[J].中国电机工程学报,2014,34(35):6304-6310. |

| LI Z H, ZHANG D L, WU Y X,et al .A new criterion for predicting deterioration of heat transfer to supercritical water in smooth tubes[J].Proceesings of the CSEE,2014,34(35):6304-6310. | |

| 17 | 樊旭 .基于能量平衡和灰平衡的CFB锅炉静态模型研究[D].保定:华北电力大学,2005. |

| FAN X .Research of CFB boiler’s static model based on the energy balance and ash balance[D].Baoding:North China Electric Power University,2005. | |

| 18 | 黄永志 .循环流化床锅炉水动力特性研究[D].上海:上海交通大学,2016. |

| HUANG Y Z .Research on water circulation characteristics of evaporating system in CFB boiler[D].Shanghai:Shanghai Jiaotong University,2016. | |

| 19 | 李银龙,董乐,牛田田,等 .660 MW超临界CFB锅炉机组跳闸后受热面安全性计算分析[J].中国电机工程学报,2021,41(17):5957-5966. doi:10.13334/j.0258-8013.pcsee.201970 |

| LI Y L, DONG L, NIU T T,et al .Calculation and analysis on the safety of heating surfaces for a 660 MW supercritical CFB boiler under boiler trip[J].Proceesings of the CSEE,2021,41(17):5957-5966. doi:10.13334/j.0258-8013.pcsee.201970 | |

| 20 | 邓博宇,张缦,李少华,等 .失电事故下350 MW超临界CFB锅炉水冷壁安全性分析[J].中国电机工程学报,2019,39(16):4799-4807. |

| DENG B Y, ZHANG M, LI S H,et al .Analysis on the safety of the water wall in a 350 MW supercritical CFB boiler under electricity failure condition[J].Proceesings of the CSEE,2019,39(16):4799-4807. | |

| 21 | 李果,周旭,周棋,等 .超临界CFB锅炉给水中断BT后水冷壁安全性分析[J].东方电气评论,2016,30(4):43-46. doi:10.3969/j.issn.1001-9006.2016.04.010 |

| LI G, ZHOU X, ZHOU Q,et al .Study of the safety of water-wall after the BT of water supply interruption of supercritical CFB boiler[J].Dongfang Electric Review,2016,30(4):43-46. doi:10.3969/j.issn.1001-9006.2016.04.010 | |

| 22 | 李银龙,杨冬,李维成,等 .660 MW超超临界CFB锅炉失电事故下受热面安全性分析及紧急补水泵选型[J].动力工程学报,2022,42(5):393-401. |

| LI Y L, YANG D, LI W C,et al .Safety analysis of heating surfaces and selection of emergency water supply pump for a 660 MW ultra-supercritical CFB boiler under power failure condition[J].Journal of Chinese Society of Power Engineering,2022,42(5):393-401. | |

| 23 | 包浩然 .循环流化床生物质气化炉内气固流动与气化特性CPFD数值模拟研究[D].包头:内蒙古科技大学,2022. |

| BAO H R .Numerical simulation of gas-solid flow and gasification characteristics in a circulating fluidized bed biomass gasifier by CPFD[D].Baotou:Inner Mongolia University of Science & Technology,2022. | |

| 24 | 董中豪,卢啸风,史丽超,等 .炉膛耐火材料热惯性对循环流化床锅炉调峰速率的影响[J].发电技术,2023,44(4):514-524. doi:10.12096/j.2096-4528.pgt.22175 |

| DONG Z H, LU X F, SHI L C,et al .Influence of thermal inertia of refractory material in furnace on the peak regulating rate of circulating fluidized bed boiler[J].Power Generation Technology,2023,44(4):514-524. doi:10.12096/j.2096-4528.pgt.22175 | |

| 25 | 张宏涛,徐冰,白玉星,等 .钢混凝土界面接触热阻试验研究[J].土木建筑与环境工程,2015,37(2):34-38. doi:10.11835/j.issn.1674-4764.2015.02.006 |

| ZHANG H T, XU B, BAI Y X,et al .Experimental analysis of the interface thermal contact resistance between steel and concrete[J].Journal of Civil and Environmental Engineering,2015,37(2):34-38. doi:10.11835/j.issn.1674-4764.2015.02.006 | |

| 26 | 牛田田,张伟强,辛胜伟,等 .超临界循环流化床锅炉屏式过热器吸热量偏差特性研究[J].中国电机工程学报,2022,42(6):2227-2238. |

| NIU T T, ZHANG W Q, XIN S W,et al .Study on the heat absorption deviation characteristics of the platen superheaters in the supercritical circulating fluidized bed boiler[J].Proceedings of the CSEE,2022,42(6):2227-2238. |

| [1] | 丁湧. 1 000 MW超超临界燃煤锅炉深度调峰研究[J]. 发电技术, 2024, 45(3): 382-391. |

| [2] | 张思海, 李超然, 万广亮, 刘印学, 徐海楠, 黄中, 杨海瑞. 330 MW 循环流化床锅炉深度调峰技术[J]. 发电技术, 2024, 45(2): 199-206. |

| [3] | 李延兵, 贾树旺, 张军亮, 符悦, 刘明, 严俊杰. 汽轮机高位布置超超临界燃煤发电系统变工况㶲经济性分析[J]. 发电技术, 2024, 45(1): 69-78. |

| [4] | 熊小鹤, 陈发林, 阮仁晖, 谭厚章, 李延森. 高温腐蚀锅炉水冷壁还原性气氛多组分同步测试试验[J]. 发电技术, 2023, 44(6): 800-808. |

| [5] | 张全斌, 周琼芳. 基于“双碳”目标的中国火力发电技术发展路径研究[J]. 发电技术, 2023, 44(2): 143-154. |

| [6] | 印欣, 张锋, 阿地利·巴拉提, 常喜强, 陈武晖, 李长军, 李雪明, 袁少伟. 新型电力系统背景下电热负荷参与实时调度研究[J]. 发电技术, 2023, 44(1): 115-124. |

| [7] | 王洪健, 王海洋, 孔皓, 周托, 张缦, 杨海瑞. 135 MW循环流化床锅炉纯燃准东煤改造策略与运行技术研究[J]. 发电技术, 2022, 43(6): 918-926. |

| [8] | 闫修峰, 宗珂, 何修年, 高林, 秦斌, 王明坤, 惠文涛. 1 000 MW煤电机组调峰中汽温控制策略研究[J]. 发电技术, 2022, 43(3): 518-522. |

| [9] | 杨美, 周云龙, 杨金福, 王迪, 韩东江, 包佳鑫. 700℃超超临界一次再热发电系统优化[J]. 发电技术, 2021, 42(4): 509-516. |

| [10] | 王婧, 杨金福, 段立强, 田李果, 荆雨田, 杨名. 高参数超超临界燃煤机组汽轮机热力系统优化设计[J]. 发电技术, 2021, 42(4): 480-488. |

| [11] | 宋晓辉, 梁恒, 陈新明, 普建国, 廖军林, 伍刚, 尹金亮. 1000MW超超临界机组调阀快关边界条件分析与应用[J]. 发电技术, 2020, 41(6): 689-696. |

| [12] | 杨金福,张忠孝,韩东江,杨美,周云龙. 新型超临界参数燃煤发电系统结构设计技术[J]. 发电技术, 2019, 40(6): 555-563. |

| [13] | 柴一占,杨震,段远源. 燃煤积灰法向光谱发射率的测量[J]. 发电技术, 2019, 40(4): 323-328. |

| [14] | 刘忠秋,张国柱,邱寅晨,张钧泰,王珊,刘明. 热电联产机组集成热泵实现热电解耦的潜力与能耗特性分析[J]. 发电技术, 2019, 40(3): 253-257. |

| [15] | 石楚,李冉,杨震,段远源. 1 000 MW燃煤机组不同负荷锅炉传热特性[J]. 发电技术, 2019, 40(3): 213-219. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||