发电技术 ›› 2024, Vol. 45 ›› Issue (1): 69-78.DOI: 10.12096/j.2096-4528.pgt.23019

李延兵1, 贾树旺1, 张军亮1, 符悦2, 刘明2, 严俊杰2

收稿日期:2023-02-20

出版日期:2024-02-29

发布日期:2024-02-29

通讯作者:

严俊杰

作者简介:基金资助:Yanbing LI1, Shuwang JIA1, Junliang ZHANG1, Yue FU2, Ming LIU2, Junjie YAN2

Received:2023-02-20

Published:2024-02-29

Online:2024-02-29

Contact:

Junjie YAN

Supported by:摘要:

可再生能源的迅速普及给电网的稳定性和可靠性带来了挑战,为了解决此问题,燃煤机组承担了调峰调频的主要任务。汽轮机高位布置技术可大幅减少耐高温材料的用量,从而提高超高参数机组的经济性。为获得汽轮机高位布置超超临界燃煤发电机组的变负荷性能,建立了㶲分析和㶲经济性分析模型,分析了不同负荷下机组的㶲经济性,获得了机组变负荷的不可逆性分布。分析结果表明:通过对系统参数进行优化,可以改善高压加热器的㶲效率;采用汽轮机高位布置技术的燃煤机组的度电成本为0.332 4元/(kW⋅h);发电的㶲价格随着负荷的升高而降低。

中图分类号:

李延兵, 贾树旺, 张军亮, 符悦, 刘明, 严俊杰. 汽轮机高位布置超超临界燃煤发电系统变工况㶲经济性分析[J]. 发电技术, 2024, 45(1): 69-78.

Yanbing LI, Shuwang JIA, Junliang ZHANG, Yue FU, Ming LIU, Junjie YAN. Exergy Economic Analysis of Ultra-Supercritical Coal-Fired Power Plants With High-Level Layout of Turbine Under Load-Cycling Conditions[J]. Power Generation Technology, 2024, 45(1): 69-78.

| 参数 | 数值 |

|---|---|

| 平均年利率ieff /% | 10 |

| 维修名义上升比率rno /% | 3 |

| 燃料名义上升比率rnf /% | 3.5 |

| 电厂运行年限n/a | 30 |

| 平均年运行时间Nop /h | 4 800 |

表1 与经济分析有关的参数

Tab. 1 Parameters related to economic analysis

| 参数 | 数值 |

|---|---|

| 平均年利率ieff /% | 10 |

| 维修名义上升比率rno /% | 3 |

| 燃料名义上升比率rnf /% | 3.5 |

| 电厂运行年限n/a | 30 |

| 平均年运行时间Nop /h | 4 800 |

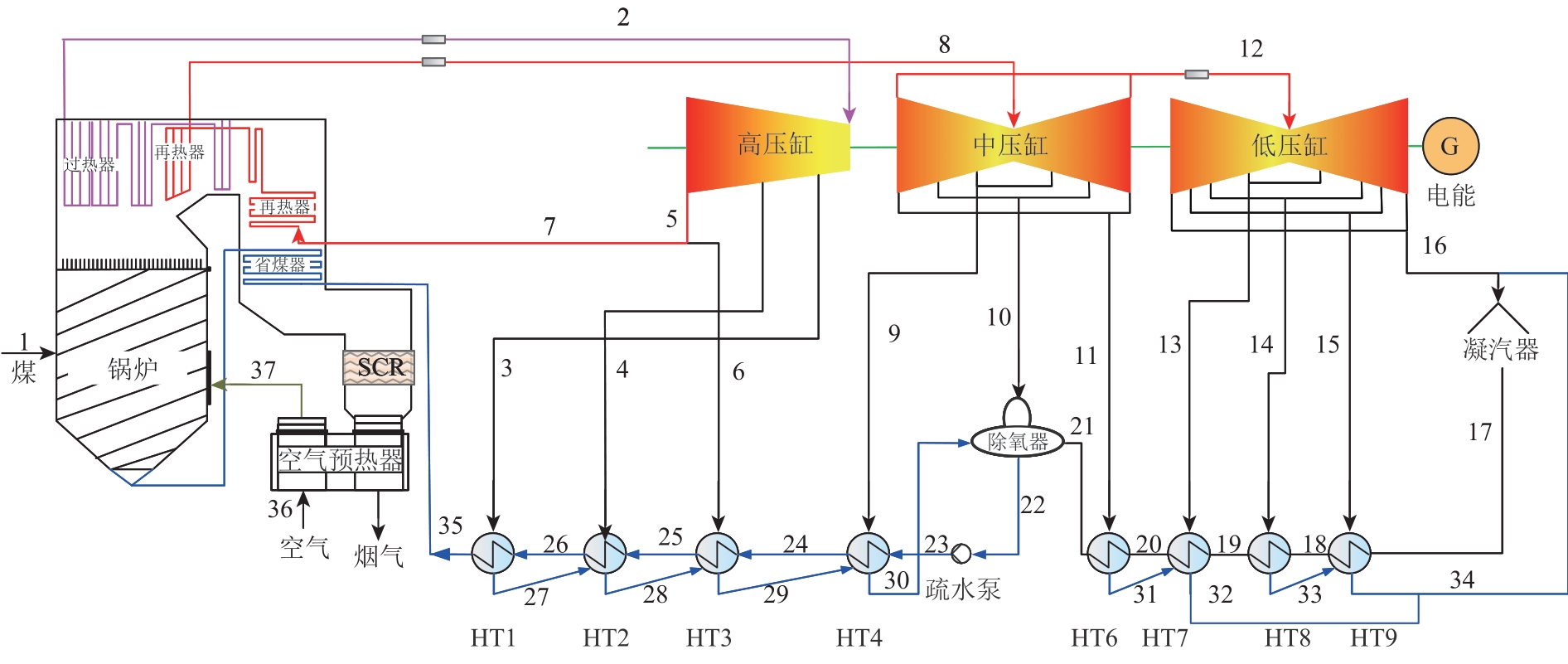

图1 采用汽轮机高位布置技术的机组系统图1—37为机组中各流股的编号;HT1—HT4为高压加热器,HT6—HT9为低压加热器,加热器按照抽汽压力由大到小编号;SCR为选择性催化还原。

Fig. 1 System diagram of the unit with high-level layout technology of turbine

| 参数 | 数值 |

|---|---|

| 额定功率/MW | 660 |

| 主蒸汽压力/MPa | 25.823 |

| 主蒸汽温度/℃ | 600 |

| 再热蒸汽压力/MPa | 5.427 |

| 再热蒸汽温度/℃ | 620 |

| 额定主蒸汽流量/(t⋅h-1) | 1 889.49 |

| 额定背压/kPa | 10.5 |

表2 机组的主要参数

Tab. 2 Main parameters of the unit

| 参数 | 数值 |

|---|---|

| 额定功率/MW | 660 |

| 主蒸汽压力/MPa | 25.823 |

| 主蒸汽温度/℃ | 600 |

| 再热蒸汽压力/MPa | 5.427 |

| 再热蒸汽温度/℃ | 620 |

| 额定主蒸汽流量/(t⋅h-1) | 1 889.49 |

| 额定背压/kPa | 10.5 |

| 参数 | 回热加热器 | |||||||

|---|---|---|---|---|---|---|---|---|

| HT2 | HT3 | HT4 | HT5 | HT6 | HT7 | HT8 | HT9 | |

| 温度/℃ | 464.10 | 422.20 | 365.10 | 501.60 | 386.30 | 294.00 | 243.20 | 130.10 |

| 压力/MPa | 11.48 | 8.77 | 5.90 | 2.60 | 1.20 | 0.59 | 0.37 | 0.12 |

表3 机组100%THA工况下回热系统参数

Tab. 3 Parameters of regenerative system under 100%THA condition of the unit

| 参数 | 回热加热器 | |||||||

|---|---|---|---|---|---|---|---|---|

| HT2 | HT3 | HT4 | HT5 | HT6 | HT7 | HT8 | HT9 | |

| 温度/℃ | 464.10 | 422.20 | 365.10 | 501.60 | 386.30 | 294.00 | 243.20 | 130.10 |

| 压力/MPa | 11.48 | 8.77 | 5.90 | 2.60 | 1.20 | 0.59 | 0.37 | 0.12 |

| 工况 | 参数 | 汽轮机抽汽压力/MPa | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| p1 | p2 | p3 | p4 | p5 | p6 | p7 | p8 | p9 | ||

| THA | 原始数据 | 11.477 | 8.769 | 5.899 | 2.600 | 1.197 | 0.591 | 0.371 | 0.117 | 0.046 |

| 计算数据 | 11.477 | 8.769 | 5.899 | 2.600 | 1.197 | 0.591 | 0.371 | 0.117 | 0.046 | |

| 绝对误差 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 75%THA | 原始数据 | 8.409 | 6.463 | 4.360 | 1.940 | 0.917 | 0.455 | 0.287 | 0.091 | 0.036 |

| 计算数据 | 8.409 | 6.463 | 4.360 | 1.940 | 0.917 | 0.455 | 0.287 | 0.091 | 0.036 | |

| 绝对误差 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50%THA | 原始数据 | 5.675 | 4.383 | 2.959 | 1.330 | 0.643 | 0.321 | 0.203 | 0.064 | 0.025 |

| 计算数据 | 5.675 | 4.383 | 2.959 | 1.330 | 0.643 | 0.321 | 0.203 | 0.064 | 0.025 | |

| 绝对误差 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| TRL | 原始数据 | 11.477 | 8.769 | 5.899 | 2.600 | 1.197 | 0.591 | 0.371 | 0.117 | 0.046 |

| 计算数据 | 11.477 | 8.769 | 5.899 | 2.600 | 1.197 | 0.591 | 0.371 | 0.117 | 0.046 | |

| 绝对误差 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

表4 汽轮机抽汽压力模拟数据和实际数据对比

Tab. 4 Comparison of simulated and actual turbine pumping pressure data

| 工况 | 参数 | 汽轮机抽汽压力/MPa | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| p1 | p2 | p3 | p4 | p5 | p6 | p7 | p8 | p9 | ||

| THA | 原始数据 | 11.477 | 8.769 | 5.899 | 2.600 | 1.197 | 0.591 | 0.371 | 0.117 | 0.046 |

| 计算数据 | 11.477 | 8.769 | 5.899 | 2.600 | 1.197 | 0.591 | 0.371 | 0.117 | 0.046 | |

| 绝对误差 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 75%THA | 原始数据 | 8.409 | 6.463 | 4.360 | 1.940 | 0.917 | 0.455 | 0.287 | 0.091 | 0.036 |

| 计算数据 | 8.409 | 6.463 | 4.360 | 1.940 | 0.917 | 0.455 | 0.287 | 0.091 | 0.036 | |

| 绝对误差 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| 50%THA | 原始数据 | 5.675 | 4.383 | 2.959 | 1.330 | 0.643 | 0.321 | 0.203 | 0.064 | 0.025 |

| 计算数据 | 5.675 | 4.383 | 2.959 | 1.330 | 0.643 | 0.321 | 0.203 | 0.064 | 0.025 | |

| 绝对误差 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| TRL | 原始数据 | 11.477 | 8.769 | 5.899 | 2.600 | 1.197 | 0.591 | 0.371 | 0.117 | 0.046 |

| 计算数据 | 11.477 | 8.769 | 5.899 | 2.600 | 1.197 | 0.591 | 0.371 | 0.117 | 0.046 | |

| 绝对误差 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

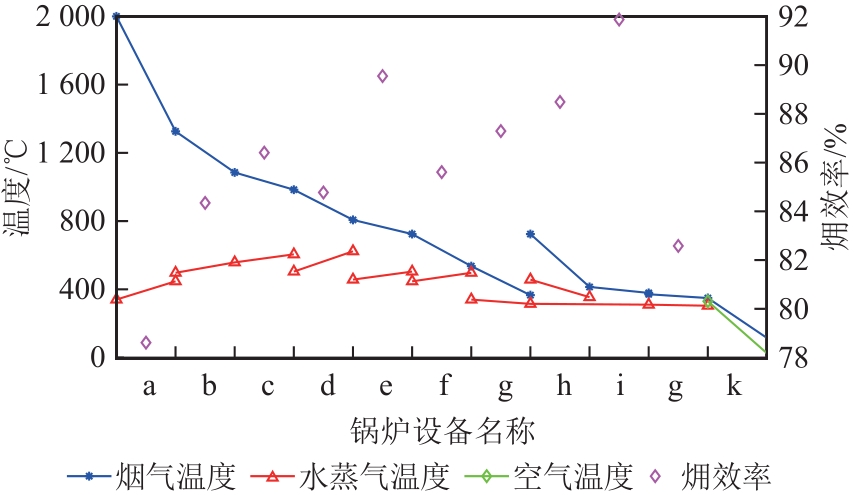

图2 锅炉中各设备的温度和㶲效率变化a—炉膛;b—屏式过热器;c—高温过热器;d—高温再热器;e—低温再热器垂直段;f—低温过热器;g—低过侧省煤器;h—低温再热器水平段;i—低再侧省煤器;j—分级省煤器;k—空气预热器。

Fig. 2 Change of temperature and exergy efficiency of each equipment in the boiler

| 参数 | 设计煤种 | 校核煤种 |

|---|---|---|

| 低位发热量/(kJ/kg) | 19 652 | 18 057 |

| 水分质量分数/% | 16.01 | 21.00 |

| 灰分质量分数/% | 17.32 | 16.02 |

| 干燥无灰基挥发分质量分数/% | 37.66 | 33.33 |

| C质量分数/% | 52.50 | 49.10 |

| H质量分数/% | 3.03 | 2.86 |

| O质量分数/% | 9.96 | 9.82 |

| N质量分数/% | 0.54 | 0.51 |

| S质量分数/% | 0.64 | 0.68 |

| 可磨性系数 | 63 | 62 |

表5 煤种特性参数

Tab. 5 Characteristic parameters of coal types

| 参数 | 设计煤种 | 校核煤种 |

|---|---|---|

| 低位发热量/(kJ/kg) | 19 652 | 18 057 |

| 水分质量分数/% | 16.01 | 21.00 |

| 灰分质量分数/% | 17.32 | 16.02 |

| 干燥无灰基挥发分质量分数/% | 37.66 | 33.33 |

| C质量分数/% | 52.50 | 49.10 |

| H质量分数/% | 3.03 | 2.86 |

| O质量分数/% | 9.96 | 9.82 |

| N质量分数/% | 0.54 | 0.51 |

| S质量分数/% | 0.64 | 0.68 |

| 可磨性系数 | 63 | 62 |

| 受热面名称 | 管道尺寸 | 受热面积/m2 | 材料 | 总质量/t | 质量因子FBM | ||

|---|---|---|---|---|---|---|---|

| 直径/mm | 壁厚/mm | ||||||

| 炉膛 | 螺旋水冷壁 | 35.0 | 6.5 | 9 000 | 15CrMo | 457 | 1.0 |

| 垂直水冷壁 | 32.0 | 8.0 | 4 600 | 12CrMoG | 238 | 1.0 | |

| 屏式过热器 | 51.0 | 8.0/9.0 | 4 500 | SA-213TP347H | 300 | 3.0 | |

| 高温过热器 | 51.0 | 6.0/8.0 | 6 500 | SA-213TP347H | 320 | 3.0 | |

| 高温再热器 | 44.5 | 6.5/9.0 | 9 000 | SA-213T92 | 350 | 3.0 | |

| 低温再热器垂直段 | 51.0 | 6.9/9.0 | 3 000 | SA-213T91 | 600 | 1.5 | |

| 低温再热器水平段 | 51.0 | 6.9/10.0 | 2 000 | SA-213T92 | 600 | 1.5 | |

| 低温过热器 | 51.0 | 8.0/10.0 | 4 018 | 12CrMoVG, 15CrMoG | 120 | 1.0 | |

| 低过侧省煤器 | 51.0 | 9.0 | 15 000 | SA-201C | 900 | 0.8 | |

| 低再侧省煤器 | 51.0 | 9.0 | 15 000 | SA-202C | 900 | 0.8 | |

| 分级省煤器 | 51.0 | 9.0 | 30 000 | SA-203C | 1 000 | 0.8 | |

表6 锅炉中各设备尺寸及材料参数

Tab. 6 Dimensions and material parameters of each equipment in the boiler

| 受热面名称 | 管道尺寸 | 受热面积/m2 | 材料 | 总质量/t | 质量因子FBM | ||

|---|---|---|---|---|---|---|---|

| 直径/mm | 壁厚/mm | ||||||

| 炉膛 | 螺旋水冷壁 | 35.0 | 6.5 | 9 000 | 15CrMo | 457 | 1.0 |

| 垂直水冷壁 | 32.0 | 8.0 | 4 600 | 12CrMoG | 238 | 1.0 | |

| 屏式过热器 | 51.0 | 8.0/9.0 | 4 500 | SA-213TP347H | 300 | 3.0 | |

| 高温过热器 | 51.0 | 6.0/8.0 | 6 500 | SA-213TP347H | 320 | 3.0 | |

| 高温再热器 | 44.5 | 6.5/9.0 | 9 000 | SA-213T92 | 350 | 3.0 | |

| 低温再热器垂直段 | 51.0 | 6.9/9.0 | 3 000 | SA-213T91 | 600 | 1.5 | |

| 低温再热器水平段 | 51.0 | 6.9/10.0 | 2 000 | SA-213T92 | 600 | 1.5 | |

| 低温过热器 | 51.0 | 8.0/10.0 | 4 018 | 12CrMoVG, 15CrMoG | 120 | 1.0 | |

| 低过侧省煤器 | 51.0 | 9.0 | 15 000 | SA-201C | 900 | 0.8 | |

| 低再侧省煤器 | 51.0 | 9.0 | 15 000 | SA-202C | 900 | 0.8 | |

| 分级省煤器 | 51.0 | 9.0 | 30 000 | SA-203C | 1 000 | 0.8 | |

| 设备名称 | 质量因子FBM |

|---|---|

| 锅炉及其各附件 | 2.8 |

| 汽轮机 | 6.0 |

| 电机 | 1.7 |

| 空气式凝汽器 | 2.5 |

| 泵 | 1.5 |

表7 机组中各设备的质量因子

Tab. 7 Quality factors of each equipment in the unit

| 设备名称 | 质量因子FBM |

|---|---|

| 锅炉及其各附件 | 2.8 |

| 汽轮机 | 6.0 |

| 电机 | 1.7 |

| 空气式凝汽器 | 2.5 |

| 泵 | 1.5 |

| 流股编号 | 压力/MPa | 温度/℃ | 质量流量/(kg/s) | 焓值/(kJ/kg) | 㶲/MW | 价格/(元/MJ) |

|---|---|---|---|---|---|---|

| 2 | 25.820 0 | 600 | 521 | 3 486 | 833.78 | 1 |

| 3 | 11.480 0 | 464 | 0 | 3 259 | 0 | 1 |

| 4 | 8.770 0 | 422 | 37 | 3 186 | 46.87 | 1 |

| 5 | 5.900 0 | 365 | 485 | 3 088 | 572.32 | 1 |

| 6 | 5.900 0 | 365 | 51 | 3 088 | 60.40 | 1 |

| 7 | 5.900 0 | 365 | 434 | 3 088 | 511.92 | 1 |

| 8 | 5.430 0 | 620 | 434 | 3 710 | 670.40 | 0.374 3 |

| 9 | 2.600 0 | 502 | 23 | 3 465 | 29.80 | 0.374 3 |

| 10 | 1.200 0 | 386 | 20 | 3 232 | 20.95 | 0.374 3 |

| 11 | 0.590 0 | 294 | 12 | 3 050 | 10.07 | 0.374 3 |

| 12 | 0.580 0 | 294 | 379 | 2 952 | 325.79 | 0.374 3 |

| 13 | 0.370 0 | 243 | 23 | 2 952 | 17.47 | 0.374 3 |

| 14 | 0.120 0 | 130 | 17 | 2 735 | 8.87 | 0.374 3 |

| 15 | 0.050 0 | 79 | 18 | 2 594 | 6.68 | 0.374 3 |

| 16 | 0.010 5 | 47 | 230 | 2 410 | 35.41 | 0.374 3 |

| 17 | 0.010 5 | 47 | 390 | 200 | 4 736.47 | 0.465 4 |

| 18 | 3.710 0 | 75 | 390 | 316 | 1.32 | 0.466 1 |

| 19 | 3.710 0 | 100 | 390 | 421 | 7.52 | 0.228 9 |

| 20 | 3.710 0 | 136 | 390 | 575 | 14.57 | 0.228 4 |

| 21 | 3.710 0 | 153 | 390 | 648 | 28.81 | 0.088 3 |

| 22 | 1.130 0 | 185 | 521 | 787 | 37.03 | 0.296 2 |

| 23 | 38.740 0 | 191 | 521 | 829 | 93.98 | 0.296 2 |

| 24 | 38.740 0 | 223 | 521 | 971 | 121.97 | 0.203 1 |

| 25 | 38.740 0 | 273 | 521 | 1 194 | 171.72 | 0.271 8 |

| 26 | 38.740 0 | 301 | 521 | 1 331 | 205.20 | 0.115 4 |

| 27 | 10.990 0 | 307 | 0 | 1 381 | 0.00 | 1 |

| 28 | 8.520 0 | 278 | 37 | 1 226 | 11.79 | 1 |

| 29 | 5.730 0 | 229 | 88 | 985 | 18.99 | 1 |

| 30 | 2.470 0 | 196 | 111 | 835 | 17.32 | 0.406 6 |

| 31 | 0.560 0 | 142 | 12 | 596 | 0.91 | 0.406 6 |

| 32 | 0.350 0 | 105 | 35 | 442 | 1.36 | 0.406 6 |

| 33 | 0.110 0 | 80 | 17 | 336 | 0.33 | 0.406 6 |

| 34 | 0.040 0 | 52 | 35 | 219 | 0.17 | 0.406 6 |

| 35 | 38.740 0 | 273 | 521 | 1 194 | 171.72 | 0 |

表8 机组的㶲和㶲经济性数据

Tab. 8 Exergy and exergy economic data of the unit

| 流股编号 | 压力/MPa | 温度/℃ | 质量流量/(kg/s) | 焓值/(kJ/kg) | 㶲/MW | 价格/(元/MJ) |

|---|---|---|---|---|---|---|

| 2 | 25.820 0 | 600 | 521 | 3 486 | 833.78 | 1 |

| 3 | 11.480 0 | 464 | 0 | 3 259 | 0 | 1 |

| 4 | 8.770 0 | 422 | 37 | 3 186 | 46.87 | 1 |

| 5 | 5.900 0 | 365 | 485 | 3 088 | 572.32 | 1 |

| 6 | 5.900 0 | 365 | 51 | 3 088 | 60.40 | 1 |

| 7 | 5.900 0 | 365 | 434 | 3 088 | 511.92 | 1 |

| 8 | 5.430 0 | 620 | 434 | 3 710 | 670.40 | 0.374 3 |

| 9 | 2.600 0 | 502 | 23 | 3 465 | 29.80 | 0.374 3 |

| 10 | 1.200 0 | 386 | 20 | 3 232 | 20.95 | 0.374 3 |

| 11 | 0.590 0 | 294 | 12 | 3 050 | 10.07 | 0.374 3 |

| 12 | 0.580 0 | 294 | 379 | 2 952 | 325.79 | 0.374 3 |

| 13 | 0.370 0 | 243 | 23 | 2 952 | 17.47 | 0.374 3 |

| 14 | 0.120 0 | 130 | 17 | 2 735 | 8.87 | 0.374 3 |

| 15 | 0.050 0 | 79 | 18 | 2 594 | 6.68 | 0.374 3 |

| 16 | 0.010 5 | 47 | 230 | 2 410 | 35.41 | 0.374 3 |

| 17 | 0.010 5 | 47 | 390 | 200 | 4 736.47 | 0.465 4 |

| 18 | 3.710 0 | 75 | 390 | 316 | 1.32 | 0.466 1 |

| 19 | 3.710 0 | 100 | 390 | 421 | 7.52 | 0.228 9 |

| 20 | 3.710 0 | 136 | 390 | 575 | 14.57 | 0.228 4 |

| 21 | 3.710 0 | 153 | 390 | 648 | 28.81 | 0.088 3 |

| 22 | 1.130 0 | 185 | 521 | 787 | 37.03 | 0.296 2 |

| 23 | 38.740 0 | 191 | 521 | 829 | 93.98 | 0.296 2 |

| 24 | 38.740 0 | 223 | 521 | 971 | 121.97 | 0.203 1 |

| 25 | 38.740 0 | 273 | 521 | 1 194 | 171.72 | 0.271 8 |

| 26 | 38.740 0 | 301 | 521 | 1 331 | 205.20 | 0.115 4 |

| 27 | 10.990 0 | 307 | 0 | 1 381 | 0.00 | 1 |

| 28 | 8.520 0 | 278 | 37 | 1 226 | 11.79 | 1 |

| 29 | 5.730 0 | 229 | 88 | 985 | 18.99 | 1 |

| 30 | 2.470 0 | 196 | 111 | 835 | 17.32 | 0.406 6 |

| 31 | 0.560 0 | 142 | 12 | 596 | 0.91 | 0.406 6 |

| 32 | 0.350 0 | 105 | 35 | 442 | 1.36 | 0.406 6 |

| 33 | 0.110 0 | 80 | 17 | 336 | 0.33 | 0.406 6 |

| 34 | 0.040 0 | 52 | 35 | 219 | 0.17 | 0.406 6 |

| 35 | 38.740 0 | 273 | 521 | 1 194 | 171.72 | 0 |

| 设备k | EF, k /kW | EP, k /kW | ED, k /kW | Zk /(元/s) | cF, k /(元/kJ) | cP, k /(元/kJ) |

|---|---|---|---|---|---|---|

| HP1 | 125.57 | 118.45 | 7.12 | 1.53 | 1.000 0 | 1.073 0 |

| HP2 | 39.15 | 37.73 | 1.41 | 0.65 | 1.000 0 | 1.054 7 |

| HP3 | 49.87 | 47.55 | 2.32 | 0.77 | 1.000 0 | 1.065 0 |

| IP1 | 111.20 | 106.31 | 4.89 | 1.41 | 0.374 3 | 0.404 8 |

| IP2 | 98.80 | 95.63 | 3.17 | 1.33 | 0.374 3 | 0.400 6 |

| IP3 | 68.22 | 65.74 | 2.49 | 1.00 | 0.374 3 | 0.403 7 |

| LP1 | 36.48 | 34.26 | 2.22 | 0.60 | 0.374 3 | 0.416 0 |

| LP2 | 75.71 | 70.53 | 5.17 | 1.04 | 0.374 3 | 0.416 5 |

| LP3 | 47.61 | 43.61 | 4.00 | 0.72 | 0.374 3 | 0.425 1 |

| LP4 | 61.95 | 53.60 | 8.35 | 0.43 | 0.374 3 | 0.448 2 |

| HT1 | 0 | 0 | 0 | 0.53 | 1.000 0 | 0 |

| HT2 | 34.95 | 33.47 | 1.48 | 0.53 | 1.000 0 | 0.115 4 |

| HT3 | 53.01 | 49.75 | 3.26 | 0.87 | 1.000 0 | 0.271 8 |

| HT4 | 31.30 | 27.99 | 3.31 | 0.55 | 0.374 3 | 0.203 1 |

| HT5 | 36.23 | 34.96 | 1.26 | 1.28 | 0.374 3 | 0.296 2 |

| HT6 | 9.07 | 8.22 | 0.85 | 0.21 | 0.374 3 | 0.088 3 |

| HT7 | 16.84 | 14.24 | 2.60 | 0.45 | 0.374 3 | 0.228 4 |

| HT8 | 8.42 | 7.05 | 1.37 | 0.30 | 0.374 3 | 0.228 9 |

| HT9 | 6.67 | 6.21 | 0.47 | 0.34 | 0.374 3 | 0.466 1 |

表9 各设备的㶲和㶲经济性分析

Tab. 9 Exergy and exergy economic analysis of each equipment

| 设备k | EF, k /kW | EP, k /kW | ED, k /kW | Zk /(元/s) | cF, k /(元/kJ) | cP, k /(元/kJ) |

|---|---|---|---|---|---|---|

| HP1 | 125.57 | 118.45 | 7.12 | 1.53 | 1.000 0 | 1.073 0 |

| HP2 | 39.15 | 37.73 | 1.41 | 0.65 | 1.000 0 | 1.054 7 |

| HP3 | 49.87 | 47.55 | 2.32 | 0.77 | 1.000 0 | 1.065 0 |

| IP1 | 111.20 | 106.31 | 4.89 | 1.41 | 0.374 3 | 0.404 8 |

| IP2 | 98.80 | 95.63 | 3.17 | 1.33 | 0.374 3 | 0.400 6 |

| IP3 | 68.22 | 65.74 | 2.49 | 1.00 | 0.374 3 | 0.403 7 |

| LP1 | 36.48 | 34.26 | 2.22 | 0.60 | 0.374 3 | 0.416 0 |

| LP2 | 75.71 | 70.53 | 5.17 | 1.04 | 0.374 3 | 0.416 5 |

| LP3 | 47.61 | 43.61 | 4.00 | 0.72 | 0.374 3 | 0.425 1 |

| LP4 | 61.95 | 53.60 | 8.35 | 0.43 | 0.374 3 | 0.448 2 |

| HT1 | 0 | 0 | 0 | 0.53 | 1.000 0 | 0 |

| HT2 | 34.95 | 33.47 | 1.48 | 0.53 | 1.000 0 | 0.115 4 |

| HT3 | 53.01 | 49.75 | 3.26 | 0.87 | 1.000 0 | 0.271 8 |

| HT4 | 31.30 | 27.99 | 3.31 | 0.55 | 0.374 3 | 0.203 1 |

| HT5 | 36.23 | 34.96 | 1.26 | 1.28 | 0.374 3 | 0.296 2 |

| HT6 | 9.07 | 8.22 | 0.85 | 0.21 | 0.374 3 | 0.088 3 |

| HT7 | 16.84 | 14.24 | 2.60 | 0.45 | 0.374 3 | 0.228 4 |

| HT8 | 8.42 | 7.05 | 1.37 | 0.30 | 0.374 3 | 0.228 9 |

| HT9 | 6.67 | 6.21 | 0.47 | 0.34 | 0.374 3 | 0.466 1 |

| 1 | HE F, LIU X, WANG M,et al .Energy,exergy,exergoeconomic,and environmental analyses and multi-objective optimization of a biomass-to-energy integrated thermal power plant[J].Alexandria Engineering Journal,2022,61(7):5629-5648. doi:10.1016/j.aej.2021.11.016 |

| 2 | 张国柱,张钧泰,文钰,等 .燃煤机组烟气余热及水回收系统变工况特性和调控策略[J].中国电力,2022,55(4):214-220. |

| ZHANG G Z, ZHANG J T, WEN Y,et al .Study on off-design condition characteristics and control strategy of fluegas waste heat and water recovery system of coal-fired power plants[J].Electric Power,2022,55(4):214-220. | |

| 3 | 石志鹏,石祥建,蔡丹,等 .绿电与绿氢耦合煤化工的系统建设方案[J].南方能源建设,2023,10(3):143-149. doi:10.16516/j.gedi.issn2095-8676.2023.03.016 |

| SHI Z P, SHI X J, CAI D,et al .Construction scheme for the system coupling coal chemical industry with green electricity and green hydrogen[J].Southern Energy Construction,2023,10(3):143-149. doi:10.16516/j.gedi.issn2095-8676.2023.03.016 | |

| 4 | 符悦,雷宇,刘明,等 .不同进汽温度火电机组多压冷端系统综合性能分析[J].中国电机工程学报,2022,42(1):229-238. |

| FU Y, LEI Y, LIU M,et al .Performance evaluation on multi-pressure cold-end systems of thermal power plants with different inlet temperatures[J].Proceedings of the CSEE,2022,42(1):229-238. | |

| 5 | 陈娜娜,韩小渠,穆祺伟,等 .1 000 MW燃煤机组变负荷环境影响评价[J].工程热物理学报,2019,40(1):22-27. |

| CHEN N N, HAN X Q, MU Q W,et al .Environmental impact assessment on 1 000 MW coal-fired power plant under off-design conditions[J].Journal of Engineering Thermophysics,2019,40(1):22-27. | |

| 6 | 宋畅,尹武昌,余学海,等 .1 000 MW近零排放燃煤机组细颗粒物及SO3排放和分布特征[J].中国电机工程学报,2022,42(5):1867-1875. |

| SONG C, YIN W C, YU X H,et al .Emission and distribution characteristics of fine particulate matter and SO3 in 1 000 MW near-zero emission coal-fired unit[J].Proceedings of the CSEE,2022,42(5):1867-1875. | |

| 7 | 於震跃,徐红波,郑应霞,等 .提高二次再热机组参数的技术经济研究[J].浙江电力,2022,41(9):101-106. |

| YU Z Y, XU H B, ZHENG Y X,et al .Technical and economic study on improving parameters of double reheat units[J].Zhejiang Electric Power,2022,41(9):101-106. | |

| 8 | 张全斌,周琼芳 .基于“双碳”目标的中国火力发电技术发展路径研究[J].发电技术,2023,44(2):143-154. doi:10.12096/j.2096-4528.pgt.22092 |

| ZHANG Q B, ZHOU Q F .Research on the development path of China’s thermal power generation technology based on the goal of “carbon peak and carbon neutralization”[J].Power Generation Technology,2023,44(2):143-154. doi:10.12096/j.2096-4528.pgt.22092 | |

| 9 | 周港宝,卞双,陈震宇,等 .先进超超临界机组用Inconel 617与C-HRA-2合金高温低周疲劳性能试验研究[J].动力工程学报,2022,42(5):475-483. doi:10.19805/j.cnki.jcspe.2022.05.012 |

| ZHOU G B, BIAN S, CHEN Z Y,et al .Experimental study on high-temperature low cycle fatigue performance of inconel 617 and C-HRA-2 alloys for advanced ultra-supercritical units[J].Journal of Chinese Society of Power Engineering,2022,42(5):475-483. doi:10.19805/j.cnki.jcspe.2022.05.012 | |

| 10 | XIONG J, ZHAO H, ZHANG C,et al .Thermoeconomic operation optimization of a coal-fired power plant[J].Energy,2012,42(1):486-496. doi:10.1016/j.energy.2012.03.020 |

| 11 | XU C, GAO Y, XU G,et al .A thermodynamic analysis and economic evaluation of an integrated coldend energy utilization system in a de-carbonization coal-fired power plant[J].Energy Conversion and Management,2019,180:218-230. doi:10.1016/j.enconman.2018.10.081 |

| 12 | 王婧,段立强,杨金福,等 .集成BEST的700 ℃一次再热超超临界机组回热系统节能优化[J].动力工程学报,2022,42(7):632-641. |

| WANG J, DUAN L Q, YANG J F,et al .Energy saving optimization study on regenerative system of 700 ℃ single reheat ultra-supercritical unit with BEST[J].Journal of Chinese Society of Power Engineering,2022,42(7):632-641. | |

| 13 | 张宏涛,张翼,焦林生,等 .高位布置660 MW汽轮机组设计特点与安全性研究[J].汽轮机技术,2021,63(3):167-169. doi:10.3969/j.issn.1001-5884.2021.03.002 |

| ZHANG H T, ZHANG Y, JIAO L S,et al .Design characteristics and research on safety of high-level layout 660 MW steam turbine[J].Turbine Technology,2021,63(3):167-169. doi:10.3969/j.issn.1001-5884.2021.03.002 | |

| 14 | 刘森林,周光炳,王晓,等 .高位布置H级燃机基础多点位移SRSS法可靠概率研究[J].南方能源建设,2022,9(4):159-166. doi:10.16516/j.gedi.issn2095-8676.2022.04.020 |

| LIU S L, ZHOU G B, WANG X,et al .Research on reliability probability of srss method for multi-point displacement of foundation of H-class gas turbine in high position[J].Southern Energy Construction,2022,9(4):159-166. doi:10.16516/j.gedi.issn2095-8676.2022.04.020 | |

| 15 | 郑开云 .低温场景超临界CO2循环燃煤发电系统研究[J].发电技术,2022,43(1):126-130. doi:10.12096/j.2096-4528.pgt.20018 |

| ZHENG K Y .Study on supercritical CO2 cycle coal-fired power generation system for low temperature scenario[J].Power Generation Technology,2022,43(1):126-130. doi:10.12096/j.2096-4528.pgt.20018 | |

| 16 | 张精桥,杜小军,张研 .超超临界2×660 MW汽轮机高位布置给水泵选型与优化研究[J].能源科技,2021,19(2):49-52. |

| ZHANG J Q, DU X J, ZHANG Y .Study on selection and optimization of feedwater pump for high level arranged ultra-supercritical 2×660 MW steam turbine[J].Energy Science and Technology,2021,19(2):49-52. | |

| 17 | 罗建松,叶勇健 .700 ℃先进超超临界机组概念设计方案研究[J].热力发电,2022,51(8):99-107. |

| LUO J S, YE Y J .Study on conceptual design scheme of 700 ℃ advanced ultra supercritical unit[J].Thermal Power Generation,2022,51(8):99-107. | |

| 18 | YE X, DONG Z, LU J,et al .Thermoeconomic evaluation of double-reheat coal-fired power units with carbon capture and storage and waste heat recovery using organic Rankine cycle[J].International Journal of Greenhouse Gas Control,2021,105(1):103247. doi:10.1016/j.ijggc.2020.103247 |

| 19 | WU X, SHEN J, LI Y,et al .Flexible operation of post-combustion solvent-based carbon capture for coal-fired power plants using multi-model predictive control:a simulation study[J].Fuel,2018,220:931-941. doi:10.1016/j.fuel.2018.02.061 |

| 20 | 付亦葳,谢天,屈杰 .一次、二次再热机组汽轮机高低位布置方案热经济性分析[J].热力发电,2017,46(7):1-4. |

| FU Y W, XIE T, QU J .Thermal-economic analysis for scheme of steam turbine generator placement in high and low platform separately[J].Thermal Power Generation,2017,46(7):1-4. | |

| 21 | AMROLLAHI Z, ERTESVÅG I S, BOLLAND O .Optimized process configurations of post-combustion CO2 capture for natural-gas-fired power plant:exergy analysis[J].International Journal of Greenhouse Gas Control,2011,5(6):1393-1405. doi:10.1016/j.ijggc.2011.09.004 |

| 22 | 孙宇贞,唐毅伟,李帅 .基于改进粒子群算法的超超临界燃煤机组负荷系统建模[J].系统仿真学报,2021,33(4):875-882. doi:10.16182/j.issn1004731x.joss.19-0649 |

| SUN Y Z, TANG Y W, LI S .Load system modeling of ultra-supercritical coal-fired power unit based on improved particle swarm optimization[J].Journal of System Simulation,2021,33(4):875-882. doi:10.16182/j.issn1004731x.joss.19-0649 | |

| 23 | AHMADI G R, TOGHRAIE D .Energy and exergy analysis of montazeri steam power plant in Iran[J].Renewable and Sustainable Energy Reviews,2016,56:454-463. doi:10.1016/j.rser.2015.11.074 |

| 24 | KIM S, LIM Y I, LEE D,et al .Perspectives of oxy-coal power plants equipped with CO2 capture,utilization,and storage in terms of energy,economic,and environmental impacts[J].Energy Conversion and Management,2022,273:116361. doi:10.1016/j.enconman.2022.116361 |

| 25 | ZHOU L, XU G, ZHAO S,et al .Parametric analysis and process optimization of steam cycle in double reheat ultra-supercritical power plants[J].Applied Thermal Engineering,2016,99:652-660. doi:10.1016/j.applthermaleng.2016.01.047 |

| 26 | YAN H, LIU M, WANG Z,et al .Flexibility enhancement of solar-aided coal-fired power plant under different direct normal irradiance conditions[J].Energy,2023,262:125349. doi:10.1016/j.energy.2022.125349 |

| 27 | ZHANG Z, ZHOU R, GE X,et al .Perspectives for 700 ℃ ultra-supercritical power generation:thermal safety of high-temperature heating surfaces[J].Energy,2020,190:116411. doi:10.1016/j.energy.2019.116411 |

| 28 | FU Y, ZHAO Y, LIU M,et al .Optimization of cold-end system of thermal power plants based on entropy generation minimization[J].Frontiers in Energy,2022,16(6):956-972. doi:10.1007/s11708-021-0785-5 |

| 29 | LAZZARETTO A, TSATSARONIS G .SPECO:a systematic and general methodology for calculating efficiencies and costs in thermal systems[J].Energy,2006,31(8/9):1257-1289. doi:10.1016/j.energy.2005.03.011 |

| 30 | BARTELA L, SKOREK-OSIKOWSKA A, KOTOWICZ J .An analysis of the investment risk related to the integration of a supercritical coal-fired combined heat and power plant with an absorption installation for CO2 separation[J].Applied Energy,2015,156:423-435. doi:10.1016/j.apenergy.2015.07.045 |

| 31 | SU Z, YANG L .A novel and efficient cogeneration system of waste heat recovery integrated carbon capture and dehumidification for coal-fired power plants[J].Energy Conversion and Management,2022,255:115358. doi:10.1016/j.enconman.2022.115358 |

| 32 | Chemical Engineering World Group .Analysis,synthesis and design of chemical processes[J].Chemical Engineering World,2016,51(12):129. |

| [1] | 季恩昌, 杨冬, 孙佰仲. 高水分褐煤流动性实验研究[J]. 发电技术, 2024, 45(4): 633-640. |

| [2] | 丁湧. 1 000 MW超超临界燃煤锅炉深度调峰研究[J]. 发电技术, 2024, 45(3): 382-391. |

| [3] | 邓启刚, 吕卓, 石友, 鲁佳易, 周旭, 王奥宇, 杨冬. 不带外置床的700 MW超超临界循环流化床锅炉失电后水冷壁安全计算分析[J]. 发电技术, 2024, 45(2): 240-249. |

| [4] | 蒋海威, 高明明, 李杰, 于浩洋, 岳光溪, 黄中. 生物质振动炉排炉燃烧过程建模及动态特性分析[J]. 发电技术, 2024, 45(2): 250-259. |

| [5] | 王华霆, 陈衡, 徐钢, 安吉振. 煤电升级改造背景下烟气余热利用节能效益对比评估[J]. 发电技术, 2024, 45(1): 90-98. |

| [6] | 梁岩芳, 彭姝璇, 崔永军, 罗建超, 何垚年, 白林超, 付经伦. 汽轮机轴封加热器换热性能计算[J]. 发电技术, 2023, 44(6): 817-823. |

| [7] | 苏靖程, 王志强, 屈江江, 张凯. 基于BP神经网络和支持向量回归的燃煤电厂空气预热器压差预测[J]. 发电技术, 2023, 44(4): 550-556. |

| [8] | 安吉振, 郑福豪, 刘一帆, 陈衡, 徐钢. 基于大数据分析的火电机组引风机故障预警研究[J]. 发电技术, 2023, 44(4): 557-564. |

| [9] | 张全斌, 周琼芳. 基于“双碳”目标的中国火力发电技术发展路径研究[J]. 发电技术, 2023, 44(2): 143-154. |

| [10] | 黄宇箴, 陈彦奇, 吴志聪, 徐钢, 刘彤. 碳中和背景下热电联产机组抽汽分配节能优化[J]. 发电技术, 2023, 44(1): 85-93. |

| [11] | 石红晖, 王海波, 曹蓉秀, 姚力, 晏鑫. 变工况条件下汽轮机高压缸末级气动及强度性能研究[J]. 发电技术, 2022, 43(6): 959-969. |

| [12] | 王志云, 赵玉柱, 王学栋, 张元舒. 调峰机制下供热汽轮机中压调门调节特性试验研究[J]. 发电技术, 2022, 43(6): 970-976. |

| [13] | 左启尧, 唐震, 李慧勇, 张颖, 王江峰. 电网调峰背景下汽轮机低压缸零出力技术现状综述[J]. 发电技术, 2022, 43(4): 645-654. |

| [14] | 闫修峰, 宗珂, 何修年, 高林, 秦斌, 王明坤, 惠文涛. 1 000 MW煤电机组调峰中汽温控制策略研究[J]. 发电技术, 2022, 43(3): 518-522. |

| [15] | 刘福国, 刘科, 王守恩. 基于机会约束的电厂混煤煤质和成本的Pareto前沿[J]. 发电技术, 2022, 43(1): 160-167. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||