Power Generation Technology ›› 2021, Vol. 42 ›› Issue (4): 422-430.DOI: 10.12096/j.2096-4528.pgt.21021

• Intelligent Turbine Power Generation Technology • Previous Articles Next Articles

Mingliang BAI1( ), Dongxue ZHANG2(

), Dongxue ZHANG2( ), Jinfu LIU2,*(

), Jinfu LIU2,*( ), Jiao LIU3(

), Jiao LIU3( ), Daren YU1,2(

), Daren YU1,2( )

)

Received:2021-03-23

Published:2021-08-31

Online:2021-07-22

Contact:

Jinfu LIU

Supported by:CLC Number:

Mingliang BAI, Dongxue ZHANG, Jinfu LIU, Jiao LIU, Daren YU. Anomaly Detection of Gas Turbine Hot Components Based on Deep Autoencoder and Support Vector Data Description[J]. Power Generation Technology, 2021, 42(4): 422-430.

| 参数 | 正常数据 | 异常数据 | ||

| 训练集 | 验证集 | 测试集 | ||

| 样本数目 | 2 100 | 450 | 450 | 500 |

Tab. 1 Dataset description

| 参数 | 正常数据 | 异常数据 | ||

| 训练集 | 验证集 | 测试集 | ||

| 样本数目 | 2 100 | 450 | 450 | 500 |

| 参数 | 正常数据 | 故障数据 | ||

| 训练集 | 验证集 | 测试集 | ||

| ERMSE | 0.030 3 | 0.029 9 | 0.029 5 | 0.067 3 |

Tab. 2 training result of deep autoencoder

| 参数 | 正常数据 | 故障数据 | ||

| 训练集 | 验证集 | 测试集 | ||

| ERMSE | 0.030 3 | 0.029 9 | 0.029 5 | 0.067 3 |

| 参数 | 正常数据 | 故障数据 | ||

| 训练集 | 验证集 | 测试集 | ||

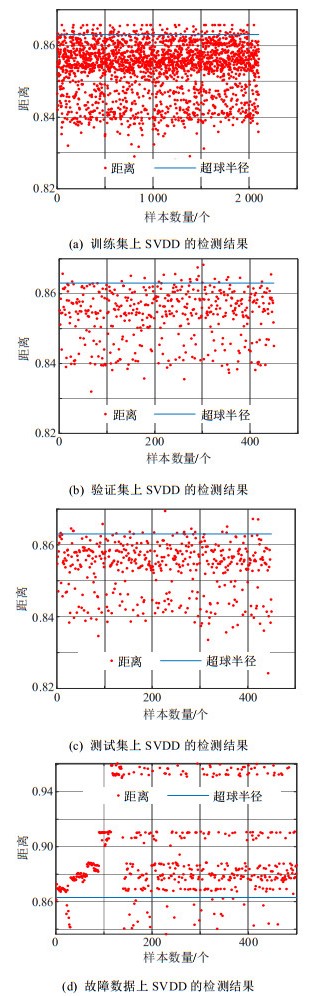

| 检测精度 | 0.969 0 | 0.968 9 | 0.982 2 | 0.946 0 |

Tab. 3 Anomaly detection accuracy of DAE-SVDD

| 参数 | 正常数据 | 故障数据 | ||

| 训练集 | 验证集 | 测试集 | ||

| 检测精度 | 0.969 0 | 0.968 9 | 0.982 2 | 0.946 0 |

Fig.10 Relationship between the distance from the center of the hypersphere and the radius of the hypersphere in the training set, validation set and test set of normal data as well as fault data

| 算法 | 正常数据 | 故障数据 | ||

| 训练集 | 验证集 | 测试集 | ||

| SVDD | 0.948 1 | 0.946 7 | 0.953 3 | 0.926 0 |

| DAE-SVDD | 0.969 0 | 0.968 9 | 0.982 2 | 0.946 0 |

Tab. 4 Anomaly detection accuracy comparison between of DAE-SVDD and SVDD

| 算法 | 正常数据 | 故障数据 | ||

| 训练集 | 验证集 | 测试集 | ||

| SVDD | 0.948 1 | 0.946 7 | 0.953 3 | 0.926 0 |

| DAE-SVDD | 0.969 0 | 0.968 9 | 0.982 2 | 0.946 0 |

| 1 | 薛晓东, 韩巍, 王晓东, 等. 适合分布式冷热电联供系统的中小型发电装置[J]. 发电技术, 2020, 41 (3): 252- 260. |

| XUE X D , HAN W , WANG X D , et al. Small and medium-scale power generation devices suiting for distributed combined cooling, heating and power system[J]. Power Generation Technology, 2020, 41 (3): 252- 260. | |

| 2 | 丁继伟, 李岩. 基于弹塑性理论的燃机转子寿命分析[J]. 发电技术, 2020, 41 (2): 202- 205. |

| DING J W , LI Y . Analysis on gas turbine rotor life based on elastoplastic theory[J]. Power Generation Technology, 2020, 41 (2): 202- 205. | |

| 3 | 苏烨, 丁俊宏, 丁宁, 等. 全国燃气轮机联合循环机组热控系统典型故障分析及预控措施建议[J]. 浙江电力, 2020, 39 (8): 95- 102. |

| SU Y , DING J H , DING N , et al. Typical fault analysis and proposals of pre-control measures for thermal control system of national gas turbine combined cycle units[J]. Zhejiang Electric Power, 2020, 39 (8): 95- 102. | |

| 4 | 杨卫国, 祝铁军, 王庆韧, 等. 燃气轮机组压气机失速引发的不稳定振动分析[J]. 广东电力, 2019, 32 (7): 37- 43. |

| YANG W G , ZHU T J , WANG Q R , et al. Analysis on unstable vibration caused by stall of gas turbine compressor[J]. Guangdong Electric Power, 2019, 32 (7): 37- 43. | |

| 5 |

朱俊杰, 王晓维, 董玉亮, 等. 基于工况辨识的重型燃气轮机性能评价方法研究[J]. 智慧电力, 2020, 48 (7): 24- 29.

DOI |

|

ZHU J J , WANG X W , DONG Y L , et al. Performance evaluation method of heavy duty gas turbine based on condition identification[J]. Smart Power, 2020, 48 (7): 24- 29.

DOI |

|

| 6 | 白明亮. 故障案例稀缺场景下的燃气轮机智能故障检测及诊断研究[D]. 哈尔滨: 哈尔滨工业大学, 2020. |

| BAI M L. Study on intelligent fault detection and diagnosis of gas turbine under the scarcity of fault cases[D]. Harbin: Harbin Institute of Technology, 2020. | |

| 7 | 刘娇. 燃气轮机高温部件故障早期预警研究[D]. 哈尔滨: 哈尔滨工业大学, 2019. |

| LIU J. Research on early warning of gas turbine high temperature components fault[D]. Harbin: Harbin Institute of Technology, 2019. | |

| 8 |

TAHAN M , TSOUTSANIS E , MUHAMMAD M , et al. Performance-based health monitoring, diagnostics and prognostics for condition-based maintenance of gas turbines: a review[J]. Applied Energy, 2017, 198, 122- 144.

DOI |

| 9 | LIN X S, LI B W, YANG X Y. Engine components fault diagnosis using an improved method of deep belief networks[C]//7th International Conference on Mechanical and Aerospace Engineering(ICMAE). IEEE, 2016: 454-459. |

| 10 | WONG P K , YANG Z , VONG C M , et al. Real-time fault diagnosis for gas turbine generator systems using extreme learning machine[J]. Neurocomputing, 2014, 128 (3): 249- 257. |

| 11 | MARAGOUDAKIS M, LOUKIS E, PANTELIDES P P. Random forests identification of gas turbine faults[C]//19th International Conference on Systems Engineering. IEEE, 2008: 127-132. |

| 12 |

WANG L , LI Y G , ABDUL GHAFIR M F , et al. A rough set-based gas turbine fault classification approach using enhanced fault signatures[J]. Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and Energy, 2011, 225 (8): 1052- 1065.

DOI |

| 13 |

LECUN Y , BENGIO Y , HINTON G , et al. Deep learning[J]. Nature, 2015, 521 (7553): 436- 444.

DOI |

| 14 |

YAN L P , DONG X Z , WANG T , et al. A fault diagnosis method for gas turbines based on improved data preprocessing and an optimization deep belief network[J]. Measurement Science and Technology, 2019, 31 (1): 151- 162.

DOI |

| 15 |

FU X Y , LUO H , ZHONG S , et al. Aircraft engine fault detection based on grouped convolutional denoising autoencoders[J]. Chinese Journal of Aeronautics, 2019, 32 (2): 296- 307.

DOI |

| 16 | MULEWICZ B , MARZEC M , MORKISZ P , et al. Failures prediction based on performance monitoring of a gas turbine: a binary classification approach[J]. Schedae Information, 2018, 38 (26): 9- 21. |

| 17 |

LIU J , LIU J , YU D , et al. Fault detection for gas turbine hot components based on a convolutional neural network[J]. Energies, 2018, 11 (8): 2149- 2158.

DOI |

| 18 | 赵志宏, 李乐豪, 杨绍普, 等. 一种频域特征提取自编码器及其在故障诊断中的应用研究[J/OL]. 中国机械工程: 1-8[2021-03-16]. http://kns.cnki.net/kcms/detail/42.1294.th.20210316.1534.006.html. |

| ZHAO Z H, LI L H, YANG S P, et al. A frequency domain feature extraction auto-encoder and its application on fault diagnosis[J/OL]. China Mechanical Engineering: 1-8[2021-03-16]. http://kns.cnki.net/kcms/detail/42.1294.th.20210316.1534.006.html. | |

| 19 | 顾珉, 施华君. 基于降噪自编码器降维的汽车行驶工况分析[J]. 计算机系统应用, 2021, 30 (1): 38- 44. |

| GU M , SHI H J . Analysis of vehicle driving condition based on de-noise autoencoder[J]. Computer Systems & Applications, 2021, 30 (1): 38- 44. | |

| 20 | 周云成, 邓寒冰, 许童羽, 等. 基于稠密自编码器的无监督番茄植株图像深度估计模型[J]. 农业工程学报, 2020, 36 (11): 182- 192. |

| ZHOU Y C , DENG H B , XU T Y , et al. Unsupervised deep estimation modeling for tomato plant image based on dense convolutional auto-encoder[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36 (11): 182- 192. | |

| 21 |

TAX D M J , DUIN R P W . Support vector data description[J]. Machine learning, 2004, 54 (1): 45- 66.

DOI |

| [1] | Zeyang CUI, Xiangling KONG, Jinglun FU, Jiajun SHI. An Image-Based Turbine Blade Parameter Inspection Method [J]. Power Generation Technology, 2024, 45(1): 106-112. |

| [2] | Yang YANG, Yaoqiang LI, Jinqi ZHANG. Design of Dome Structure for A Lean Premixed Swirled Combustor of Gas Turbine Based on the Numerical Method [J]. Power Generation Technology, 2023, 44(5): 712-721. |

| [3] | Yang YANG, Desan GUO, Yaoqiang LI, Jinqi ZHANG. Design of Lean Premixed Multi-Swirl Combustor Dome Structure for Gas Turbine [J]. Power Generation Technology, 2023, 44(2): 183-192. |

| [4] | Hongyi ZHANG, Litao QU. Research and Application of Numerical Simulation for Selective Catalytic Reduction Denitration of 9F Gas Turbine [J]. Power Generation Technology, 2023, 44(1): 78-84. |

| [5] | Jiangang HAO, Wenming GONG, Yang DING, Danwei ZHENG, Yong LIU. Analysis on Combustion Instability Characteristics of Model Swirl Combustor With Gas Fuel [J]. Power Generation Technology, 2022, 43(6): 927-934. |

| [6] | Hang ZHANG, Chuanjie ZHOU, Lin ZHANG, Jietao CHEN, Chunmei XU, Daogang PENG. Fault Diagnosis of Power Plant Induced Draft Fan Based on PNN-WNN-DS Information Fusion [J]. Power Generation Technology, 2022, 43(6): 951-958. |

| [7] | Yunfeng JIN, Chao LIU, Gaofeng DENG, Yunlong GUAN, Jiangang HAO, Haizhou HUANG, Dongxiang JIANG. Cost Benefit Analysis for Maintenance Strategy of Gas Turbine Inlet Filtration System [J]. Power Generation Technology, 2022, 43(1): 119-125. |

| [8] | Hua ZHU, Biao YAN, Yusong LIU, Liang LI. Study on Humid Air Turbine Cooling Technique [J]. Power Generation Technology, 2021, 42(4): 412-421. |

| [9] | Jin GUAN, Zongze HE, Xiaojing LÜ, Yiwu WENG. Experimental Study on Startup of 30kW Micro Gas Turbine Generator Set [J]. Power Generation Technology, 2021, 42(4): 404-411. |

| [10] | Yunfeng JIN, Chao LIU, Gaofeng DENG, Yunlong GUAN, Xin TIAN, Haizhou HUANG, Dongxiang JIANG. Research on Modeling Method of Gas Turbine Inlet Pressure Loss [J]. Power Generation Technology, 2021, 42(4): 395-403. |

| [11] | Kai WEI, Zhong LUO, Yonghang SUN, Yu WANG. Analysis of Internal Flow Characteristics of Gas Turbine Ejector Mixer with Valve Plate [J]. Power Generation Technology, 2021, 42(4): 431-436. |

| [12] | Bin QIU, Jinglun FU. Research Status of Gas Turbine Exhaust Diffuser [J]. Power Generation Technology, 2021, 42(4): 437-446. |

| [13] | Xiangling KONG, Jinglun FU. Computer-Vision Based on Three-dimensional Reconstruction Technology and Its Applications in Gas Turbine Industry [J]. Power Generation Technology, 2021, 42(4): 454-463. |

| [14] | Shangnian CHEN, Luping LI, Shihai ZHANG, Minnan OUYANG, Ang FAN, Xiankui WEN. Research Progress of Vibration Fault Diagnosis Technology for Steam Turbine Generator Sets [J]. Power Generation Technology, 2021, 42(4): 489-499. |

| [15] | Youhua HUANG, Shanwei MA, Ji LIU, Zhenghua WU. Optimization Design and Engineering Application of Gas Turbine SCR Denitrification System [J]. Power Generation Technology, 2021, 42(3): 350-356. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||