发电技术 ›› 2024, Vol. 45 ›› Issue (6): 1087-1094.DOI: 10.12096/j.2096-4528.pgt.23176

• 发电及环境保护 • 上一篇

刘卓, 陈冬林, 汪淑奇, 杨仪江, 闫优洋, 杨展

收稿日期:2024-06-20

修回日期:2024-09-25

出版日期:2024-12-31

发布日期:2024-12-30

通讯作者:

陈冬林

作者简介:基金资助:Zhuo LIU, Donglin CHEN, Shuqi WANG, Yijiang YANG, Youyang YAN, Zhan YANG

Received:2024-06-20

Revised:2024-09-25

Published:2024-12-31

Online:2024-12-30

Contact:

Donglin CHEN

Supported by:摘要:

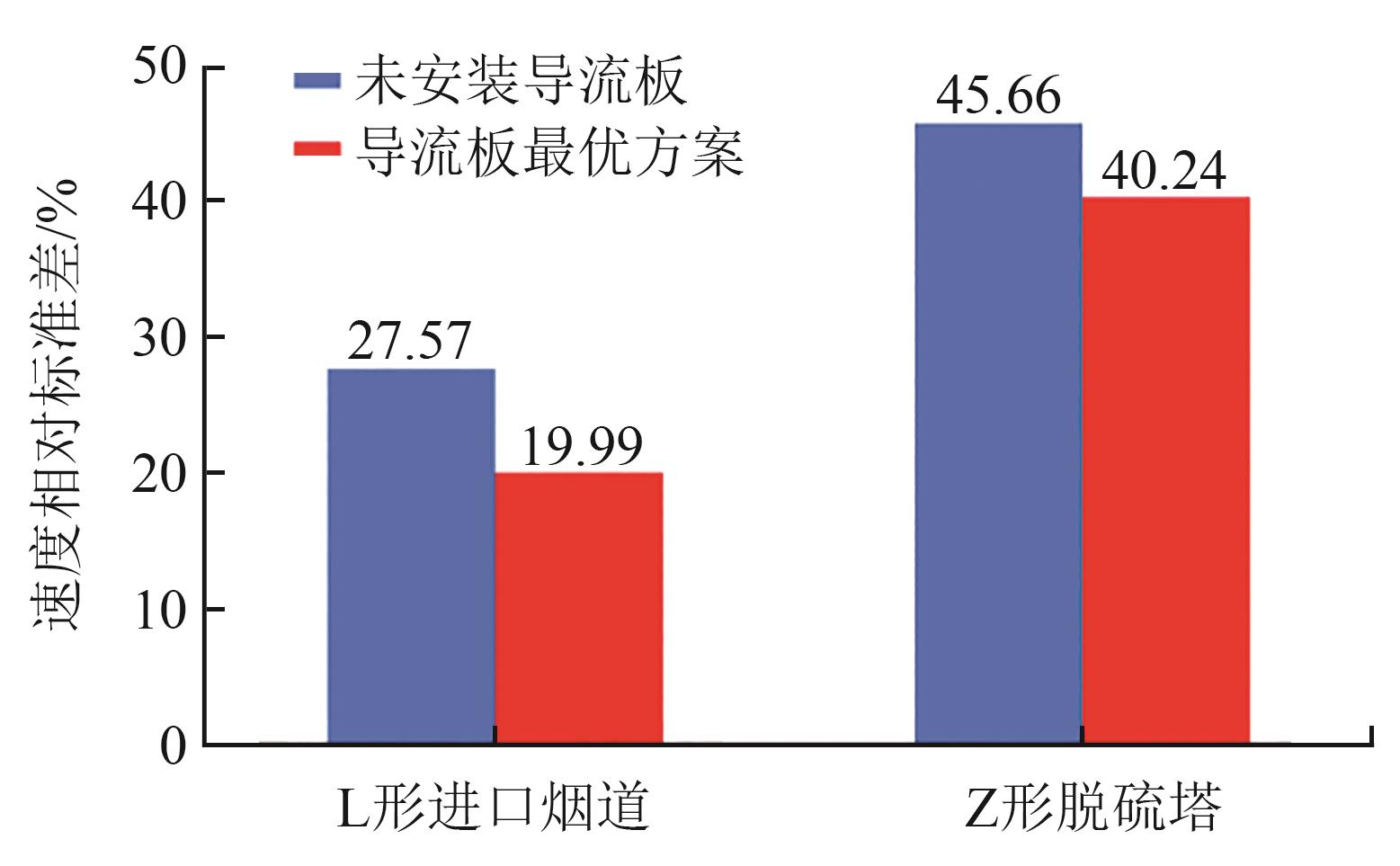

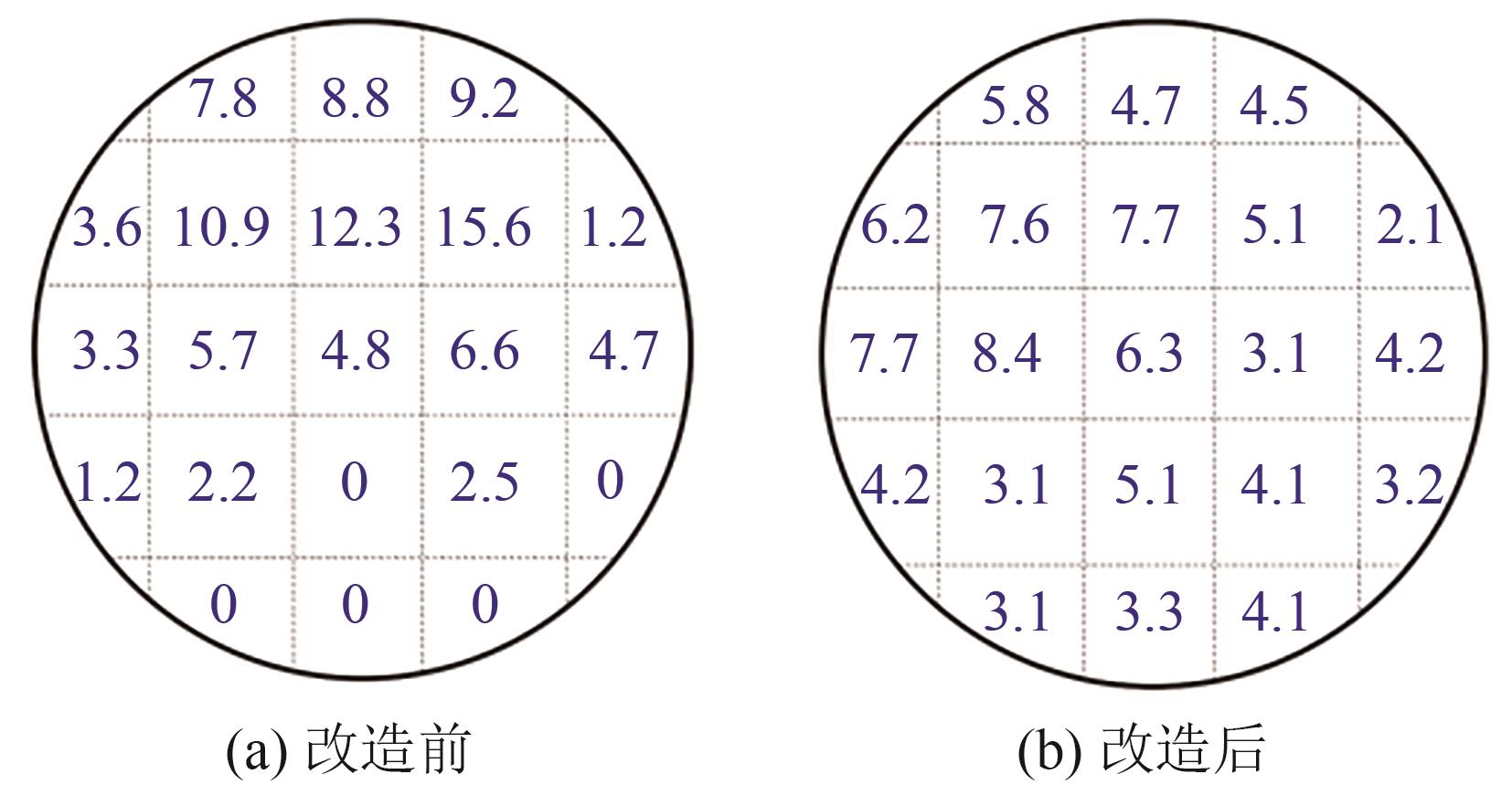

目的 脱硫塔除雾器因其结构简单、除雾效果好而广泛应用于燃煤火电厂。然而,除雾器因自身气水分离原理的局限性,容易在板面上结垢堵塞,严重时影响机组的输出功率。因此,需要解决湿法脱硫塔除雾器频繁结垢堵塞及由此造成的阻力损失过大问题。 方法 提出了采用导流板优化脱硫塔及其进口烟道流场的方法,并对优化前后的Z形脱硫塔及其L形进口烟道烟气流场进行了仿真计算和工程应用验证。 结果 仿真计算结果显示,在额定锅炉负荷工况下,优化后L形进口烟道出口截面的速度相对标准差从27.57%降至19.99%;Z形脱硫塔内除雾器入口截面的速度相对标准差从45.66%降至40.24%。同时,除雾器入口截面的浆液液滴质量流量从441.136 kg/s降至368.498 kg/s,这表明优化方案有效降低了除雾器的工作负荷。实验结果表明,改造前脱硫塔除雾器入口截面存在速度为0 m/s的区域,改造后该区域速度提升至1~5 m/s,与仿真计算结果趋势一致。改造后180天的运行数据显示,除雾器前后压差不再超过200 Pa。停机检修中实测结果显示,除雾器板面上的结垢厚度从改造前的1 cm以上减小至0.1 cm左右,严重结垢堵塞现象已消除。 结论 所提流场优化方法显著改善了脱硫塔内烟气流场的均匀性,降低了除雾器的工作负荷,有效减缓了除雾器结垢堵塞问题,具有较大的工程应用价值。

中图分类号:

刘卓, 陈冬林, 汪淑奇, 杨仪江, 闫优洋, 杨展. 减缓脱硫塔除雾器堵塞的流场优化方法[J]. 发电技术, 2024, 45(6): 1087-1094.

Zhuo LIU, Donglin CHEN, Shuqi WANG, Yijiang YANG, Youyang YAN, Zhan YANG. Optimization Method of Flow Field for Alleviating Clogging of Mist Eliminator in Desulfurization Tower[J]. Power Generation Technology, 2024, 45(6): 1087-1094.

| 三维模型 | 横向定位尺寸/m | 纵向定位尺寸/m | 横向定形尺寸/m | 纵向定形尺寸/m | 半径/m | 角度定位尺寸/(°) |

|---|---|---|---|---|---|---|

| L形进口烟道 | — | |||||

| Z形脱硫塔 | — |

表1 导流板定形、定位尺寸

Tab. 1 Shaping and positioning dimensions of guide plate

| 三维模型 | 横向定位尺寸/m | 纵向定位尺寸/m | 横向定形尺寸/m | 纵向定形尺寸/m | 半径/m | 角度定位尺寸/(°) |

|---|---|---|---|---|---|---|

| L形进口烟道 | — | |||||

| Z形脱硫塔 | — |

图10 L形进口烟道出口截面和Z形脱硫塔内除雾器入口截面的速度相对标准差

Fig. 10 Relative standard deviation of velocity of exit section of L-shaped inlet flue and entrance section of mist eliminator in Z-shaped desulphurization tower

图12 改造前后Z形脱硫塔除雾器入口截面烟气速度分布

Fig. 12 Flue gas velocity distribution at inlet cross section of mist eliminator of Z-shaped desulfurization tower before and after modification

| 1 | 夏忠林,陈文通,许书峤,等 .火电厂烟塔合一技术应用现状与现存问题分析[J].发电技术,2024,45(4):590-599. |

| XIA Z L, CHEN W T, XU S Q,et al .Application status and existing problem analysis of the natural draft cooling towers with flue gas injection technology in thermal power plants[J].Power Generation Technology,2024,45(4):590-599. | |

| 2 | 张双平,陈伟雄,贾西部,等 .脱硫塔除雾器安装高度对烟气携液量影响的模拟研究[J].发电技术,2021,42(2):247-253. doi:10.12096/j.2096-4528.pgt.20039 |

| ZHANG S P, CHEN W X, JIA X B,et al .Simulation study on influence of installation height of mist eliminator on liquid holdup of flue gas in desulfurization tower[J].Power Generation Technology,2021,42(2):247-253. doi:10.12096/j.2096-4528.pgt.20039 | |

| 3 | 禾志强,祁利明,马青树 .石灰石-石膏法脱硫系统除雾器堵塞研究[J].锅炉技术,2010,41(1):77-80. |

| HE Z Q, QI L M, MA Q S .The study of demister blocking in limestone-gypsum desulfurization technology[J].Boiler Technology,2010,41(1):77-80. | |

| 4 | 潘超群 .石灰石-石膏湿法烟气脱硫除雾器堵塞分析与对策[J].能源环境保护,2015,29(4):30-31. |

| PAN C Q .Analysis and countermeasures of clogging in limestone-gypsum wet flue gas desulfurization mist eliminator[J].Energy Environmental Protection,2015,29(4):30-31. | |

| 5 | 马晓丽,张襄平 .无GGH湿法脱硫系统除雾器堵塞原因及防堵建议[J].电力科技与环保,2012,28(2):35-36. |

| MA X L, ZHANG X P .Analysis of causes of mist eliminators blockage in wet FGD systems without GGH and its countermeasures[J].Electric Power Technology and Environmental Protection,2012,28(2):35-36. | |

| 6 | 纪小春 .折流板式除雾器的结垢与控制措施[J].黑龙江电力,2012,34(2):131-134. |

| JI X C .Scaling and its control measure of chevron mist eliminator[J].Heilongjiang Electric Power,2012,34(2):131-134. | |

| 7 | 郭东明 .脱硫工程技术与设备[M].北京:化学工业出版社,2019:165-170. |

| GUO D M .Desulfurization engineering technology and equipment[M].Beijing:Chemical Industry Press,2019:165-170. | |

| 8 | 林瑜,陈德珍,尹丽洁 .喷淋层组合方式对大型脱硫塔内流动和热湿交换过程影响的数值模拟[J].中南大学学报(自然科学版),2017,48(10):2572-2582. |

| LIN Y, CHEN D Z, YIN L J .Numerical simulation of impact of spraying layers scheme on gas-liquid two phases flow,heat and mass transfer in large scale desulphurization absorption tower[J].Journal of Central South University (Science and Technology),2017,48(10):2572-2582. | |

| 9 | 王霄,闵健,高正明,等 .脱硫吸收塔除雾器性能的实验研究和数值模拟[J].环境工程学报,2008,2(11):1529-1534. |

| WANG X, MIN J, GAO Z M,et al .Experimental study and numerical simulation of characteristics of demister of absorbing tower in desulfurization system[J].Chinese Journal of Environmental Engineering,2008,2(11):1529-1534. | |

| 10 | 尤良洲,杜振,江建平,等 .管束式除尘除雾器在脱硫串塔系统中的应用及性能评价[J].中国电力,2017,50(12):173-177. |

| YOU L Z, DU Z, JIANG J P,et al .The application and performance evalution of bundle precipitator in series absorpti tower of desnifurization system[J].Electric Power,2017,50(12):173-177. | |

| 11 | 邱桂芝,张志刚,宋寅,等 .管束式除雾器结构优化数值模拟及高效除雾器研制[J].中国电力,2018,51(5):134-140. |

| QIU G Z, ZHANG Z G, SONG Y .Numerical simulation on tube bundle demister and development of high efficiency demister[J].Electric Power,2018,51(5):134-140. | |

| 12 | 李文鼎,高惠华,蔡文丰 .石灰石-石膏湿法脱硫吸收塔结垢分析及预防措施[J].发电技术,2019,40(1):51-55. |

| LI W D, GAO H H, CAI W F .Scaling analysis and preventive measures of limestone-gypsum wet flue gas desulfurization[J].Power Generation Technology,2019,40 (1):51-55. | |

| 13 | AZZOPARDI J B, SANAULLAH S K .Re-entrainment in wave-plate mist eliminators[J].Chemical Engineering Science,2002,57(17):3557-3563. doi:10.1016/s0009-2509(02)00270-1 |

| 14 | MAO F, TIAN R F, CHEN Y X,et al .Re-entrainment in and optimization of a vane mist eliminator[J].Annals of Nuclear Energy,2018,120(11):656-665. doi:10.1016/j.anucene.2018.06.011 |

| 15 | 张维蔚,吕凡,庄晓凤,等 .弯管二次流及电厂锅炉均流技术的研究进展[J].热能动力工程,2014,29(6):603-609. |

| ZHANG W W, LV F, ZHUANG X F,et al .Research progress of secondary flow in bent pipe and flow sharing technology in power plant boiler[J].Thermal Power Engineering,2014,29(6):603-609. | |

| 16 | 田森浩,向勇林,陈冬林,等 .内置导流板的湿法脱硫塔数值模拟优化及应用[J].动力工程学报,2021,41(9):766-772. |

| TIAN S H, XIANG Y L, CHEN D L,et al .Numerical simulation optimization and application of wet desulfurization tower with inner guide plate[J].Journal of Chinese Society of Power Engineering,2021,41(9):766-772. | |

| 17 | 陈慧敏,李香龙,刘秀兰,等 .大功率充电连接器相变冷却换热特性研究[J].电力科学与技术学报,2024,39(1):201-207. |

| CHEN H M, LI X L, LIU X L,et al .Study of phase change cooling heat transfer characteristics of high power charging connectors[J].Journal of Electric Power Science and Technology,2024,39(1):201-207. | |

| 18 | 李子新,王硕,赵隆,等 .多参数影响的导线热稳监测及动态增容研究[J].智慧电力,2022,50(12):100-106. |

| LI Z X, WANG S, ZHAO L,et al .Thermal stability monitoring of conductor and dynamic line rating considering effects of multiple parameters[J].Smart Power,2022,50(12):100-106. | |

| 19 | 张育平,刘俊,王沣浩,等 .中深层U型对接井取热能力影响因素显著性分析[J].可再生能源,2022,40(11):1473-1480. |

| ZHANG Y P, LIU J, WANG F H,et al .Significance analysis on the influence factors of thermal extraction capacity of medium-deep U-shaped butted well[J].Renewable Energy Resources,2022,40(11):1473-1480. | |

| 20 | 郭胜江,吴广庆,陈国邦 .适用于回流区流体力学模拟计算的三种高雷诺数湍流模型的比较[J].制冷学报,2005,26(3):26-29. |

| GUO S J, WU G Q, CHEN G B .Comparison of three high-reynolds-number models in recirculation zones for simulation of computational fluid dynamics[J].Journal of Refrigeration,2005,26(3):26-29. | |

| 21 | 张井龙,王尊策,徐艳 .壁面处理对壁面旋转旋流器流动模拟的影响分析[J].数学的实践与认识,2022,52(10):142-146. |

| ZHANG J L, WANG Z C, XU Y .Analysis of effect of near-wall treatments on numerical computation of rotating hydrocyclone[J].Journal of Mathematics in Practice and Theory,2022,52(10):142-146. | |

| 22 | 王新光,毛枚良,何琨,等 .壁面函数在超声速湍流模拟中的应用[J].航空学报,2022,43(9):290-298. |

| WANG X G, MAO M L, HE K,et al .Application of wall function to supersonic turbulence simulation[J].Acta Aeronautica et Astronautica Sinica,2022,43(9):290-298. | |

| 23 | 张涛,朱晓军,彭飞,等 .近壁面处理对湍流数值计算的影响分析[J].海军工程大学学报,2013,25(6):104-108. |

| ZHANG T, ZHU X J, PENG F,et al .Analysis of effect of near-wall treatments on numerical computation of turbulent flow[J].Journal of Naval University of Engineering,2013,25(6):104-108. | |

| 24 | 杨丁 .湿法烟气脱硫吸收塔阻力特性实验研究[J].中国环保产业,2018(5):31-36. |

| YANG D .Experimental study on absorber resistance characteristic of WFGD[J].China Environmental Protection Industry,2018(5):31-36. | |

| 25 | 刘文斌,李璐璐,李晓金,等 .脱硫湿烟气喷淋冷凝过程中的参数优化研究[J].发电技术,2023,44(1):107-114. doi:10.12096/j.2096-4528.pgt.21064 |

| LIU W B, LI L L, LI X J,et al .Study on parameter optimization of desulfurized wet flue gas in spray condensation process[J].Power Generation Technology,2023,44(1):107-114. doi:10.12096/j.2096-4528.pgt.21064 | |

| 26 | 蒋惠梦,谷小兵,余苏玲,等 .湿法烟气脱硫喷淋塔的阻力特性研究[J].环境保护科学,2017,43(3):85-90. |

| JIANG H M, GU X B, YU S L,et al .Research of resistance characteristics of wet flue gas desulfurization spraying scrubber[J].Environmental Protection Science,2017,43(3):85-90. | |

| 27 | 冉景煜,邓庆波,牛俊天,等 .湿法脱硫塔内流场均匀性影响因素及其评价方法[J].动力工程学报,2020,40(10):825-831. |

| RAN J Y, DENG Q B, NIU J T,et al .Influence factors and evaluation method on the uniformity of flow field in a WFGD tower[J].Journal of Chinese Society of Power Engineering,2020,40(10):825-831. |

| [1] | 刘更生, 张建永, 孙权, 曹山, 宫安琪, 姜林, 张永生. 300 MW燃煤机组超高石灰铝沉淀耦合活性炭吸附脱除废水中重金属研究[J]. 发电技术, 2024, 45(5): 959-968. |

| [2] | 夏忠林, 陈文通, 许书峤, 吴忠胜, 谢强, 马双忱, 马京香. 火电厂烟塔合一技术应用现状与现存问题分析[J]. 发电技术, 2024, 45(4): 590-599. |

| [3] | 丁湧. 1 000 MW超超临界燃煤锅炉深度调峰研究[J]. 发电技术, 2024, 45(3): 382-391. |

| [4] | 屠楠, 刘家琛, 徐静, 方嘉宾, 马彦花. 管壳式相变蓄热器的蓄释热过程性能分析[J]. 发电技术, 2024, 45(3): 508-516. |

| [5] | 刘学, 李国栋, 张瑞颖, 侯一晨, 陈磊, 杨立军. 电站空冷岛轴流风机模型研究[J]. 发电技术, 2024, 45(3): 545-557. |

| [6] | 张思海, 李超然, 万广亮, 刘印学, 徐海楠, 黄中, 杨海瑞. 330 MW 循环流化床锅炉深度调峰技术[J]. 发电技术, 2024, 45(2): 199-206. |

| [7] | 邓启刚, 吕卓, 石友, 鲁佳易, 周旭, 王奥宇, 杨冬. 不带外置床的700 MW超超临界循环流化床锅炉失电后水冷壁安全计算分析[J]. 发电技术, 2024, 45(2): 240-249. |

| [8] | 龚思琦, 云再鹏, 许明, 敖乐, 李初福, 黄凯, 孙晨. 基于三元催化剂的固体氧化物燃料电池尾气催化燃烧数值模拟[J]. 发电技术, 2024, 45(2): 331-340. |

| [9] | 熊小鹤, 陈发林, 阮仁晖, 谭厚章, 李延森. 高温腐蚀锅炉水冷壁还原性气氛多组分同步测试试验[J]. 发电技术, 2023, 44(6): 800-808. |

| [10] | 梁中荣, 蓝茂蔚, 郑国, 何荣强, 屈可扬, 甘云华. 基于最小二乘支持向量机的电站锅炉高效率低NO x 的多目标优化研究[J]. 发电技术, 2023, 44(6): 809-816. |

| [11] | 杨旸, 李耀强, 张金琦. 基于数值方法的燃气轮机贫预混旋流燃烧室单头部结构设计[J]. 发电技术, 2023, 44(5): 712-721. |

| [12] | 王林. 5 MW超临界二氧化碳机组锅炉闭式循环吹管工艺研究[J]. 发电技术, 2023, 44(5): 731-737. |

| [13] | 张立峰, 李晶, 王智. 基于主成分分析和深度神经网络的声学层析成像温度分布重建[J]. 发电技术, 2023, 44(3): 399-406. |

| [14] | 尹桃柱, 张永生, 汪涛, 王家伟. 硫掺杂多孔碳材料的制备及其对脱硫废水中重金属的电吸附性能研究[J]. 发电技术, 2023, 44(3): 382-391. |

| [15] | 张全斌, 周琼芳. 基于“双碳”目标的中国火力发电技术发展路径研究[J]. 发电技术, 2023, 44(2): 143-154. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||