发电技术 ›› 2026, Vol. 47 ›› Issue (1): 38-52.DOI: 10.12096/j.2096-4528.pgt.260104

赵玲芳1,2, 孙喜2, 杨昊2, 窦南南2, 董贝贝3

收稿日期:2025-03-04

修回日期:2025-04-29

出版日期:2026-02-28

发布日期:2026-02-12

通讯作者:

董贝贝

作者简介:基金资助:Lingfang ZHAO1,2, Xi SUN2, Hao YANG2, Nannan DOU2, Beibei DONG3

Received:2025-03-04

Revised:2025-04-29

Published:2026-02-28

Online:2026-02-12

Contact:

Beibei DONG

Supported by:摘要:

目的 高温固体氧化物电解池(solid oxide electrolysis cell,SOEC)技术因其高效率、环境友好和余热利用等优势,被视为实现可持续制氢的关键技术之一。为此,对SOEC技术的产业化发展进行了系统性梳理和展望,以期为我国电解水制氢领域提供众多场景化案例。 方法 首先,对SOEC技术在国内外的研究进展、市场应用及产业化过程中面临的挑战进行了深入分析;其次,评估了SOEC技术在不同应用场景下的应用潜力和相关技术方案;最后,结合国内外主要SOEC技术厂商和相关项目案例,对SOEC技术的未来发展前景及趋势进行了探讨。 结论 SOEC技术作为实现可持续制氢的关键途径,其产业化进程亟需打通上下游产业链的协同发展壁垒,同时为实现其大规模应用,需要通过技术创新解决一系列关键技术难题。随着技术的成熟,SOEC有望在化工、分布式发电等领域获得广泛应用,为实现全球能源需求和脱碳目标做出重大贡献。

中图分类号:

赵玲芳, 孙喜, 杨昊, 窦南南, 董贝贝. 固体氧化物电解池技术产业化发展研究进展[J]. 发电技术, 2026, 47(1): 38-52.

Lingfang ZHAO, Xi SUN, Hao YANG, Nannan DOU, Beibei DONG. Research Progress on Industrialization of Solid Oxide Electrolysis Cell Technology[J]. Power Generation Technology, 2026, 47(1): 38-52.

| 特性 | 碱性电解水制氢 | 质子交换膜电解水制氢 | 高温固体氧化物电解水制氢 |

|---|---|---|---|

| 能源效率/% | 59~70 | 65~82 | 85~100 |

| 运行温度/℃ | 60~80 | 50~90 | 600~1 000 |

| 电流密度/(A⋅cm-2) | 0.2~0.5 | 1.0~3.0 | 0.3~2.0 |

| 能耗/(kW⋅h⋅m-3) | 4.2~5.9 | 4.2~4.6 | >3.0 |

| 启停速度 | 较快 | 快 | 慢 |

| 电能质量需求 | 稳定电源 | 可以采用波动电源 | 稳定电源 |

| 电解质 | 5 mol⋅L-1 KOH/NaOH | 固体聚合物电解质 | 钇稳定的氧化锆 |

| 电解槽成本/(美元/kW) | 880~1 650 | 1 540~2 550 | >2 000 |

| 安全性 | 较差 | 较好 | 较差 |

| 技术成熟度 | 技术成熟,已实现大规模工业应用,成本低 | 有较好的可再生能源适应性,无污染,但成本高,商业化水平低 | 部分电能被热能取代,能源转化效率高,但高温限制材料选择,且尚未实现工业化 |

| 国外代表企业 | 法国Mcphy、美国Teledyne、挪威Nel | 美国Proton、加拿大Hydrogenics | 丹麦Haldor Topsoe、德国Sunfire |

| 国内代表企业 | 苏州竞立、天津大陆制氢、中船重工718所 | 大连化物所、中船重工718所、中电丰业、安思卓、中国航天科技507所 | 大连化物所、清华大学、宁波材料所、北京低碳所 |

表1 3种电解水制氢技术比较

Tab. 1 Comparison of three water electrolysis technologies for hydrogen production

| 特性 | 碱性电解水制氢 | 质子交换膜电解水制氢 | 高温固体氧化物电解水制氢 |

|---|---|---|---|

| 能源效率/% | 59~70 | 65~82 | 85~100 |

| 运行温度/℃ | 60~80 | 50~90 | 600~1 000 |

| 电流密度/(A⋅cm-2) | 0.2~0.5 | 1.0~3.0 | 0.3~2.0 |

| 能耗/(kW⋅h⋅m-3) | 4.2~5.9 | 4.2~4.6 | >3.0 |

| 启停速度 | 较快 | 快 | 慢 |

| 电能质量需求 | 稳定电源 | 可以采用波动电源 | 稳定电源 |

| 电解质 | 5 mol⋅L-1 KOH/NaOH | 固体聚合物电解质 | 钇稳定的氧化锆 |

| 电解槽成本/(美元/kW) | 880~1 650 | 1 540~2 550 | >2 000 |

| 安全性 | 较差 | 较好 | 较差 |

| 技术成熟度 | 技术成熟,已实现大规模工业应用,成本低 | 有较好的可再生能源适应性,无污染,但成本高,商业化水平低 | 部分电能被热能取代,能源转化效率高,但高温限制材料选择,且尚未实现工业化 |

| 国外代表企业 | 法国Mcphy、美国Teledyne、挪威Nel | 美国Proton、加拿大Hydrogenics | 丹麦Haldor Topsoe、德国Sunfire |

| 国内代表企业 | 苏州竞立、天津大陆制氢、中船重工718所 | 大连化物所、中船重工718所、中电丰业、安思卓、中国航天科技507所 | 大连化物所、清华大学、宁波材料所、北京低碳所 |

| 模式 | LHV效率/% | HHV效率/% |

|---|---|---|

| SOEC(含蒸汽发生器) | 60.5 | 71.1 |

| SOEC(无蒸汽发生器) | 72.0 | 84.4 |

| SOEC(无蒸汽发生器和压缩机) | 84.5 | 99.3 |

| SOFC | 49.2 | 42.1 |

表2 RSOC系统效率比较

Tab. 2 Comparison of RSOC system efficiencies

| 模式 | LHV效率/% | HHV效率/% |

|---|---|---|

| SOEC(含蒸汽发生器) | 60.5 | 71.1 |

| SOEC(无蒸汽发生器) | 72.0 | 84.4 |

| SOEC(无蒸汽发生器和压缩机) | 84.5 | 99.3 |

| SOFC | 49.2 | 42.1 |

图5 上海应用物理研究所研制的200 kW级高温固体氧化物电解水制氢验证装置

Fig. 5 A 200 kW high-temperature solid oxide water electrolysis hydrogen production validation system developed by Shanghai Institute of Applied Physics

| 参数 | 运行模式 | ||

|---|---|---|---|

| 电解模式 | HFC模式 | NGFC模式 | |

| 交流电输入功率 | (142.9±11.4) kW | — | — |

| 交流电输出功率 | — | (30.0±3.0) kW | (25.0±2.5) kW |

| 氢气产量 | (40.0±2.0) m3/h | — | — |

| 蒸汽消耗量 | (45.0±2.5) kg/h | — | — |

| 氢气消耗量 | — | (21.3±3.2) m3/h | — |

| 天然气消耗量 | — | — | (5.3±0.8) m3/h |

| 动态范围 | 50%~125% | 30%~100% | 30%~100% |

| 交流电系统效率 | 84%±2% | 47%±2% | 50%±2% |

表3 RSOC设备在额定运行时的规格

Tab. 3 RSOC unit specifications under nominal operation

| 参数 | 运行模式 | ||

|---|---|---|---|

| 电解模式 | HFC模式 | NGFC模式 | |

| 交流电输入功率 | (142.9±11.4) kW | — | — |

| 交流电输出功率 | — | (30.0±3.0) kW | (25.0±2.5) kW |

| 氢气产量 | (40.0±2.0) m3/h | — | — |

| 蒸汽消耗量 | (45.0±2.5) kg/h | — | — |

| 氢气消耗量 | — | (21.3±3.2) m3/h | — |

| 天然气消耗量 | — | — | (5.3±0.8) m3/h |

| 动态范围 | 50%~125% | 30%~100% | 30%~100% |

| 交流电系统效率 | 84%±2% | 47%±2% | 50%±2% |

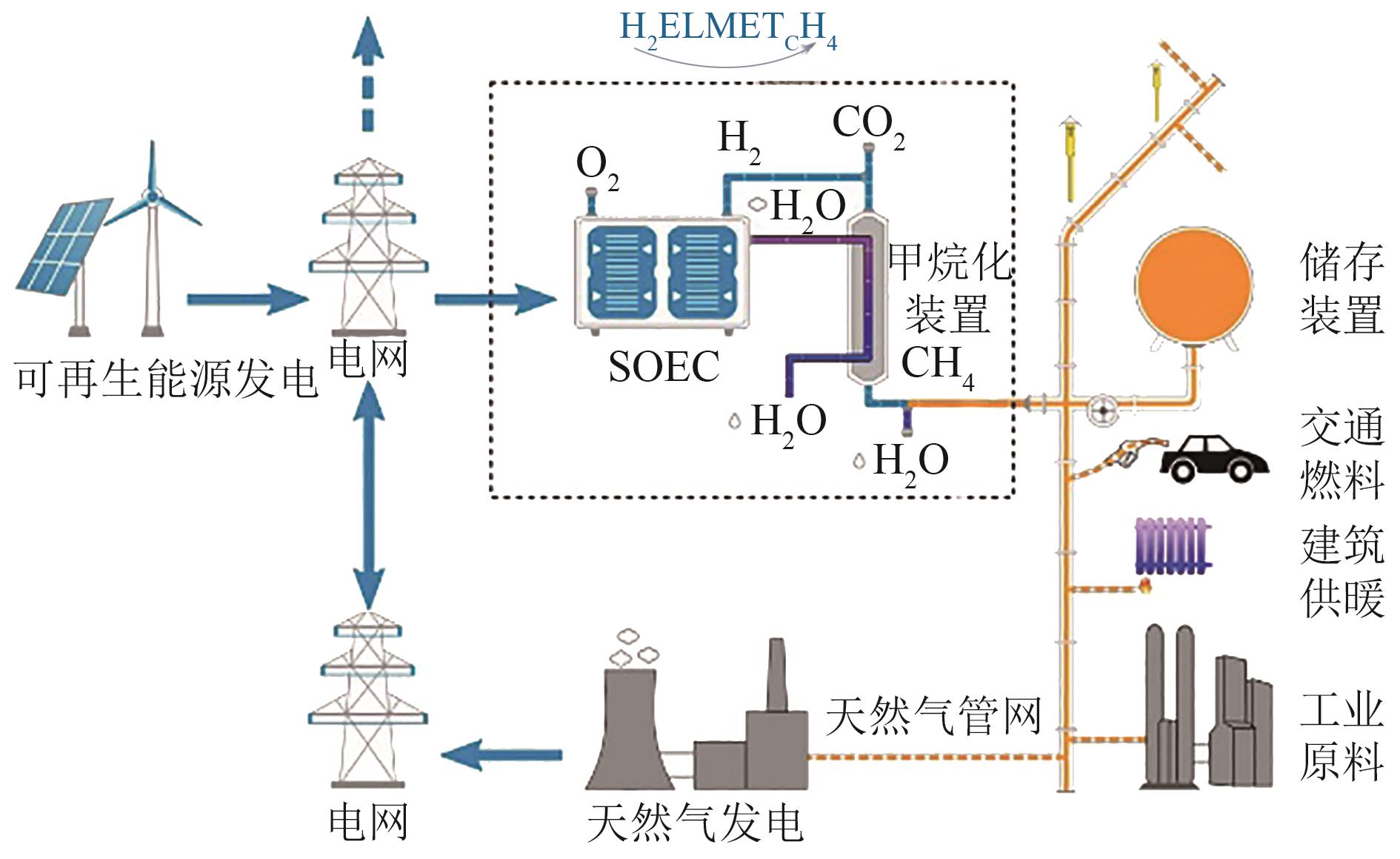

图7 通过连接甲烷化装置和高温电解槽生成合成天然气的HELMETH概念

Fig. 7 HELMETH concept for synthetic natural gas generation by integration of a methanation unit with a high-temperature electrolyser

| [1] | 孟翔宇,邬新国,顾阿伦,等 .国际氢能发展战略及对中国的启示[J].前瞻科技,2024,3(4):121-133. |

| MENG X Y, WU X G, GU A L,et al .International hydrogen energy development strategy and its enlightenment to China[J].Science and Technology Foresight,2024,3(4):121-133. | |

| [2] | 陈佳睿,武佳璇,周国鹏,等 .基于SWOT及层次分析法的粤港澳大湾区氢能产业发展建议[J].发电技术,2025,46(6):1112-1122. |

| CHEN J R, WU J X, ZHOU G P,et al .Recommendations for hydrogen energy industry development in Guangdong-Hong Kong-Macao Greater Bay Area based on SWOT and analytic hierarchy processJ].Power Generation Technology,2025,46(6):1112-1122. | |

| [3] | 吉平,林伟芳,冯长有,等 .氢能发电技术发展制约因素及未来方向综述[J].全球能源互联网,2025,8(2):165-175. |

| JI P, LIN W F, FENG C Y,et al .Review on the development constraints and directions of hydrogen power generation technology[J].Journal of Global Energy Interconnection,2025,8(2):165-175. | |

| [4] | 李谚斐,施训鹏, SHIGERU Kimura .氢能的经济与社会影响:东亚峰会地区案例[J].南方能源建设,2025,12(3):1-19. |

| LI Y F, SHI X P, SHIGERU K .Economic and social impacts of hydrogen energy:East Asia summit region case study[J].Southern Energy Construction,2025,12(3):1-19. | |

| [5] | 朱凯,张艳红 .“双碳”形势下电力行业氢能应用研究[J].发电技术,2022,43(1):65-72. doi:10.12096/j.2096-4528.pgt.21098 |

| ZHU K, ZHANG Y H .Research on application of hydrogen in power industry under“double carbon”circumstance[J].Power Generation Technology,2022,43(1):65-72. doi:10.12096/j.2096-4528.pgt.21098 | |

| [6] | 胡旭,安锐坚,杜宇晨,等 .欧洲-北非氢能协同发展研究[J].中国电力,2024,57(7):151-162. |

| HU X, AN R J, DU Y C,et al .Research on Europe-North Africa hydrogen coordinated development[J].Electric Power,2024,57(7):151-162. | |

| [7] | 中能传媒研究院 .2024年中国能源大数据报告[R/OL].(2024-06-27)[2025-01-09].. |

| China Energy Media Research Institute .China energy big data report (2024)[R/OL].(2024-06-27) [2025-01-09].. | |

| [8] | 中商产业研究院 .2024年中国氢气产量及需求量预测分析:产量达 3 500万吨(图)[EB/OL].(2024-08-21)[2025-01-09].. |

| China Business Industry Research Institute .2024 China’s hydrogen production and demand forecast analysis:production reaches 35 million tons (Figure)[EB/OL].(2024-08-21)[2025-01-09].. | |

| [9] | 张明震,张灿,吴秀山,等 .水资源对我国绿氢产业的影响分析[J].南方能源建设,2024,11(2):172-178. |

| ZHANG M Z, ZHANG C, WU X S,et al .Analysis of the impact of water resources on China’s green hydrogen industry[J].Southern Energy Construction,2024,11(2):172-178. | |

| [10] | 张丝钰,张宁,代红才,等 .可再生能源电解水制氢系统规划优化与生产模拟[J].中国电力,2024,57(4):52-60. |

| ZHANG S Y, ZHANG N, DAI H C,et al .Optimization and simulation on hydrogen production system using water electrolysis powered by renewable energy[J].Electric Power,2024,57(4):52-60. | |

| [11] | 金子儿,王子缘,李亚杰,等 .我国海上风电制氢产业发展现状、问题与展望[J].南方能源建设,2025,12(3):33-41. |

| JIN Z E, WANG Z Y, LI Y J,et al .Development status,problems and prospects of offshore wind hydrogen production industry in China[J].Southern Energy Construction,2025,12(3):33-41. | |

| [12] | 申刘飞,翟雨佳,吴星徵,等 .海上超导风电制氢一体化研究进展与发展趋势[J].电工技术学报,2025,40(11):3362-3380. |

| SHEN L F, ZHAI Y J, WU X Z,et al .Progress and development trend of integrated research on hydrogen production from offshore superconducting wind power[J].Transactions of China Electrotechnical Society,2025,40(11):3362-3380. | |

| [13] | 苗梦薇,于瑞佼,陈浩,等 .太阳能电解水制氢系统性能与稳定性分析[J].南方能源建设,2025,12(3):144-153. |

| MIAO M W, YU R J, CHEN H,et al .Performance and stability analysis of a hydrogen production system based on solar electrolysis of water[J].Southern Energy Construction,2025,12(3):144-153. | |

| [14] | 杨博,张子健 .基于人工智能的可再生能源电解水制氢关键技术及发展前景分析[J].发电技术,2025,46(3):482-495. |

| YANG B, ZHANG Z J .Analysis of key technologies and development prospects for renewable energy-powered water electrolysis for hydrogen production based on artificial intelligence[J].Power Generation Technology,2025,46(3):482-495. | |

| [15] | 张正,宋凌珺 .电解水制氢技术:进展、挑战与未来展望[J].工程科学学报,2025,47(2):282-295. |

| ZHANG Z, SONG L J .Hydrogen production by water electrolysis:advances,challenges and future prospects[J].Chinese Journal of Engineering,2025,47(2):282-295. | |

| [16] | 王海龙,刘书贤,王东,等 .固体氧化物电解池(SOEC)共电解H2O和CO2的研究进展[J].当代化工研究,2023(2):20-23. |

| WANG H L, LIU S X, WANG D,et al .Research progress on co-electrolysis of H2O and CO2 in solid oxide electrolytic cell (SOEC)[J].Modern Chemical Research,2023(2):20-23. | |

| [17] | CHEN Y, WU X G, HU H R,et al .System level performance analysis and parameter optimization of hydrogen production based on solid oxide electrolytic cell[J].Applied Energy,2023,347:121329. doi:10.1016/j.apenergy.2023.121329 |

| [18] | 刘明义,郑建涛,徐海卫,等 .电解水制氢技术在可再生能源发电领域的应用[C]//2013年中国电机工程学会年会论文集.成都:中国电机工程学会,2013:2598-2603. |

| LIU M Y, ZHENG J T, XU H W,et al .Application of hydrogen generation from electrolyzed water in renewable energy power generation[C]//2013 Annual Meeting of the Chinese Society of Electrical Engineering.Chengdu:China Society of Electrical Engineering,2013:2598-2603. | |

| [19] | U. S. Department of Energy.U. S. DOE hydrogen program and national clean hydrogen strategy[R/OL].(2024-01)[2025-01-09].. |

| [20] | KÜNGAS R, BLENNOW P, HEIREDAL-CLAUSEN T,et al .eCOs-a commercial CO2 electrolysis system developed by haldor topsoe[J].ECS Transactions,2017,78(1):2879-2884. doi:10.1149/07801.2879ecst |

| [21] | Topsoe Haldor .CO production decarbonized-convert CO2 into carbon monoxide using Topsoe’s eCOsTM electrolysis technology[EB/OL].(2025-01-09)[2025-01-09].. |

| [22] | Topsoe Haldor .eREACTTM [EB/OL].(2025-01-09) [2025-01-09].. |

| [23] | EBBESEN S B, MOGENSEN M B .Electrolysis of carbon dioxide in solid oxide electrolysis cells[J].Journal of power sources,2009,193:349. doi:10.1016/j.jpowsour.2009.02.093 |

| [24] | KÜNGAS R, BLENNOW P, HEIREDAL-CLAUSEN T,et al .Increasing the lifetime of stacks in CO2 electrolysis[C]//Proceedings of the 13th European SOFC and SOEC Forum.Lucerne,2018:B1503. doi:10.1149/09101.2601ecst |

| [25] | KAPLAN V, WACHTEL E, GARTSMAN K,et al .Conversion of CO2 to CO by electrolysis of molten lithium carbonate[J].Journal of the Electrochemical Society,2010,157:B552. doi:10.1149/1.3308596 |

| [26] | VERMA S, HAMASAKI Y, KIM C,et al .Insights into the low overpotential electroreduction of CO2 to CO on a supported gold catalyst in an alkaline flow electrolyzer[J].ACS Energy Letters,2018,3:193. doi:10.1021/acsenergylett.7b01096 |

| [27] | MA S, LUO R, GOLD J I,et al .Carbon nanotube containing Ag catalyst layers for efficient and selective reduction of carbon dioxide[J].Journal of Materials Chemistry A,2016,4:8573. doi:10.1039/c6ta00427j |

| [28] | KUTZ R B, CHEN Q, YANG H,et al .Sustainion imidazolium-functionalized polymers for carbon dioxide electrolysis[J].Energy Technology,2017,5:929. doi:10.1002/ente.201600636 |

| [29] | KACZUR J J, YANG H, LIU Z,et al .Carbon dioxide and water electrolysis using new alkaline stable anion membranes[J].Frontiers in Chemistry,2018,6:263. doi:10.3389/fchem.2018.00263 |

| [30] | DUFEK E J, LISTER T E, STONE S G,et al .Operation of a pressurized system for continuous reduction of CO2 [J].Journal of the Electrochemical Society,2012,159:F514. doi:10.1149/2.011209jes |

| [31] | ENDŐDI B, KECSENOVITY E, SAMU A,et al .Multilayer electrolyzer stack converts carbon dioxide to gas products at high pressure with high efficiency[J].ACS Energy Letters,2019,4:1770. doi:10.1021/acsenergylett.9b01142 |

| [32] | HAAS T, KRAUSE R, WEBER R,et al .Technical photosynthesis involving CO2 electrolysis and fermentation[J].Nature Catalysis,2018,1:32. doi:10.1038/s41929-017-0005-1 |

| [33] | KÜNGAS R .Review:electrochemical CO2 reduction for CO production:comparison of low-and high-temperature electrolysis technologies[J].Journal of the Electrochemical Society,2020,167(4):044508. doi:10.1149/1945-7111/ab7099 |

| [34] | Topsoe Haldor .Which technology to choose for direct electrochemical conversion of CO2 into chemicals?[EB/OL].(2020-04-23)[2025-01-09].. |

| [35] | 王姝琼 .沼气生物脱硫技术的应用研究[D].北京:北京石油化工学院,2019. |

| WANG S Q .Application of biological desulfurization technology of biogas[D].Beijing:Beijing Institute of Petrochemical Technology,2019. | |

| [36] | FROM T N, PARTOON B, RAUTENBACH M,et al .Electrified steam methane reforming of biogas for sustainable syngas manufacturing and next-generation of plant design:a pilot plant study[J].Chemical Engineering Journal,2024,479:147205. doi:10.1016/j.cej.2023.147205 |

| [37] | 王瑶,刘通 .甲烷辅助高温电解制氢气和合成气[J].硅酸盐学报,2021,49(1):189-201. |

| WANG Y, LIU T .Methane-assisted solid oxide electrolysis cell for hydrogen and synthesis gas production[J].Journal of the Chinese Ceramic Society,2021,49(1):189-201. | |

| [38] | Topsoe Haldor .Important milestone:synthetic crude produced from biogas and CO2 in power to liquids demo[EB/OL].(2024-11-29)[2025-01-09].. |

| [39] | KÜNGAS R, BLENNOW P, HEIREDAL-CLAUSEN T,et al .Progress in SOEC development activities at haldor topsøe[J].ECS Transactions,2019,91(1):215-223. doi:10.1149/09101.0215ecst |

| [40] | Topsoe Haldor .Topsoe and Aramco sign joint development agreement to advance low-carbon hydrogen solutions using eREACTTM [EB/OL].(2024-11-27)[2025-01-09].. |

| [41] | 高工氢电 .世界SOEC品牌“竞跑”,中外差距在哪?[EB/OL].(2024-08-05) [2025-01-09].. |

| Hydrogen & Electric GG .World SOEC brand “race”,where is the gap between China and foreign countries?[EB/OL].(2024-08-05) [2025-01-09].. | |

| [42] | Sunfire .Sunfire supplies Boeing with world’s largest commercial reversible electrolysis (RSOC) system[EB/OL].(2016-02-29)[2025-01-09].. |

| [43] | POSDZIECH O, SCHWARZE K, BRABANDT J .Efficient hydrogen production for industry and electricity storage via high-temperature electrolysis[J].International Journal of Hydrogen Energy,2019,44(35):19089-19101. doi:10.1016/j.ijhydene.2018.05.169 |

| [44] | 李程,周露,刘波,等 .固体氧化物电解池氢电极材料研究进展[J].硅酸盐学报,2024,52(6):1884-1899. |

| LI C, ZHOU L, LIU B,et al .Recent progress on hydrogen electrode materials for solid oxide electrolysis cell[J].Journal of the Chinese Ceramic Society,2024,52(6):1884-1899. | |

| [45] | 牟树君,林今,邢学韬,等 .高温固体氧化物电解水制氢储能技术及应用展望[J].电网技术,2017,41(10):3385-3391. |

| MU S J, LIN J, XING X T,et al .Technology and application prospect of high-temperature solid oxide electrolysis cell[J].Power System Technology,2017,41(10):3385-3391. | |

| [46] | 张文强,于波 .高温固体氧化物电解制氢技术发展现状与展望[J].电化学,2020,26(2):212-229. |

| ZHANG W Q, YU B .Development status and prospects of hydrogen production by high temperature solid oxide electrolysis[J].Journal of Electrochemistry,2020,26(2):212-229. | |

| [47] | 上海应用物理研究所 .上海应物所成功实现十千瓦级固体氧化物共电解二氧化碳/水蒸气制备氢碳比可调的合成气技术[EB/OL].(2023-11-14) [2025-01-09].. |

| Shanghai Institute of Applied Physics .Shanghai Institute of Applied Physics (SIAP) successfully realizes ten-kilowatt-scale solid oxide co-electrolysis of carbon dioxide/water vapor to prepare syngas with adjustable hydrogen-carbon ratio [EB/OL].(2023-11-14)[2025-01-09].. | |

| [48] | 上海应用物理研究所 .上海应物所200 kW高温制氢装置一次开车成功并顺利通过项目验收[EB/OL].(2023-03-22)[2025-01-09].. doi:10.62539/2949-5644-2025-6-1-13-22 |

| Shanghai Institute of Applied Physics .Shanghai Institute of Applied Physics (SIAP) 200 kW high-temperature hydrogen production plant successfully started up and passed the project acceptance[EB/OL].(2023-03-22)[2025-01-09].. doi:10.62539/2949-5644-2025-6-1-13-22 | |

| [49] | LI X X, WANG Y D, LIU W,et al .Reliability of CO2 electrolysis by solid oxide electrolysis cells with a flat tube based on a composite double-sided air electrode[J].Composites Part B:Engineering,2019,166:549-554. doi:10.1016/j.compositesb.2019.02.012 |

| [50] | LU L M, LIU W, WANG J X,et al .Long-term stability of carbon dioxide electrolysis in a large-scale flat-tube solid oxide electrolysis cell based on double-sided air electrodes[J].Applied Energy,2020,259:114130. doi:10.1016/j.apenergy.2019.114130 |

| [51] | 宁波材料技术与工程研究所 .宁波材料所在基于SOEC电解CO2合成燃料技术方面取得系列进展[EB/OL].(2022-07-24)[2025-01-09].. |

| Ningbo Institute of Materials Technology and Engineering .Ningbo Institute of Materials Technology and Engineering (NIMT) has made a series of progress in fuel synthesis technology based on SOEC electrolysis of CO2 [EB/OL].(2022-07-24) [2025-01-09].. | |

| [52] | 葛奔,艾德生,林旭平,等 .固体氧化物电解池技术应用研究进展[J].科技导报,2017,35(8):37-46. |

| GE B, AI D S, LIN X P,et al .Progress on application of solid oxide electrolysis cells[J].Science & Technology Review,2017,35(8):37-46. | |

| [53] | HERRING J S, O’BRIEN J E, STOOTS C M,et al .Progress in high-temperature electrolysis for hydrogen production using planar SOFC technology[J].International Journal of Hydrogen Energy,2007,32(4):440-450. doi:10.1016/j.ijhydene.2006.06.061 |

| [54] | 王平 .高温固体氧化物电解池应用领域研究进展[J].现代化工,2024,44(11):81-84. |

| WANG P .Research progress in application fields of high-temperature solid oxide electrolysis cell[J].Modern Chemical Industry,2024,44(11):81-84. | |

| [55] | LARGE钜大 .国内电解制氢与氢储能发展现状[EB/OL].(2020-02-21)[2025-01-09].. |

| LARGE JuDa .Development status of domestic electrolytic hydrogen production and hydrogen energy storage[EB/OL].(2020-02-21) [2025-01-09].. | |

| [56] | Sunfire .GrInHy2.0:Sunfire delivers the world’s largest high-temperature electrolyzer to Salzgitter Flachstahl[J].M2 Presswire,2020. |

| [57] | 张俊杰,孙旺,高啸天,等 .固体氧化物电解池制氢关键技术及产业化进展[J].化工学报,2023,74(12):4749-4763. |

| ZHANG J J, SUN W, GAO X T,et al .Key technology and industrialization progress of hydrogen production by solid oxide electrolytic cell[J].CIESC Journal,2023,74(12):4749-4763. | |

| [58] | 电堆科技 .电堆科技SOEC-CH4制氢系统最新研发进展[EB/OL].(2024-08-08) [2025-01-09].. |

| Denso Technology .Latest R&D progress of Denso Technology’s SOEC-CH4 hydrogen production system [EB/OL].(2024-08-08)[2025-01-09].. | |

| [59] | 中国化工报 .百千瓦级SOEC电解水制氢项目开建[EB/OL].(2024-03-22)[2025-01-09].. |

| China Chemical News .Hundred-kilowatt-scale SOEC electrolytic water-to-hydrogen project begins construction[EB/OL].(2024-03-22)[2025-01-09].. | |

| [60] | 科学导报 .我国首个百千瓦SOEC电解水制氢侧线装置示范运行[EB/OL].(2024-11-26) [2025-01-09].. |

| Herald Science .Demonstration operation of China’s first 100-kilowatt SOEC electrolytic water-to-hydrogen sideline unit[EB].(2024-11-26) [2025-01-09].. | |

| [61] | POSDZIECH O, GEIßLER T, SCHWARZE K,et al .System development and demonstration of large-scale high-temperature electrolysis[J].ECS Transactions,2019,91(1):2537-2546. doi:10.1149/09101.2537ecst |

| [62] | Sunfire .The GrInHy project:green hydrogen for steelworks[EB/OL].(2016-08-30)[2025-01-09].. |

| [63] | 柴瑞环,杨昆,房超运,等 .“双碳”目标下含碳捕集与电转气的综合能源系统优化调度[J].电测与仪表,2025,62(7):21-29. |

| CHAI R H, YANG K, FANG C Y,et al .Optimal scheduling of integrated energy system with carbon capture and power-to-gas under “double carbon”target[J].Electrical Measurement & Instrumentation,2025,62(7):21-29. | |

| [64] | Commission European .Integrated high-temperature electrolysis and methanation for effective power to gas conversion[EB/OL].(2024-06-18)[2025-01-09].. |

| [65] | HELMETH. Integrated P 2G process[EB/OL].(2024-12-03)[2025-01-09].. |

| [66] | MultiPLHY .Multimegawatt high-temperature electrolyser to generate green hydrogen for production of high-quality biofuels[EB/OL].(2024-12-03)[2025-01-09].. |

| [67] | MultiPLHY .About[EB/OL].(2024-12-03)[2025-01-09].. |

| [68] | MultiPLHY .MULTIPLHY project presented at the EU Hydrogen Week 2024 in Brussels[EB/OL].(2024-12-03)[2025-01-09].. |

| [69] | MultiPLHY .Consortium[EB/OL].(2025-12-03)[2025-01-09].. |

| [70] | 艾邦氢能源技术网 .翌晶领航丨国内首条SOEC电堆自动化产线下线及新品发布[EB/OL].(2023-04-25)[2025-01-09].. |

| Ebond Hydrogen Energy Technology .Nextgen leads the way丨Domestic first SOEC reactor automated production line launched and new products released[EB/OL].(2023-04-25)[2025-01-09].. |

| [1] | 王志康, 张儒琪, 袁少可, 韩东江, 隋军. 有机朗肯-蒸汽压缩循环系统研究进展[J]. 发电技术, 2025, 46(6): 1059-1073. |

| [2] | 罗斌, 白小龙, 臧天磊, 黄燕, 张琳, 李萌, 张雪霞, 蒋永龙. 风光水互补发电系统研究综述[J]. 发电技术, 2025, 46(6): 1097-1111. |

| [3] | 陈佳睿, 武佳璇, 周国鹏, 康俊杰, 宋庆彬. 基于SWOT及层次分析法的粤港澳大湾区氢能产业发展建议[J]. 发电技术, 2025, 46(6): 1112-1122. |

| [4] | 王曦, 陈心怡. 一种基于时序卷积网络-Transformer的海上风电功率预测方法[J]. 发电技术, 2025, 46(6): 1123-1132. |

| [5] | 陈梦东, 康伟, 邓占锋, 赵文强, 雷国斌. 低气压环境下固体蓄热材料的蓄释热特性研究[J]. 发电技术, 2025, 46(6): 1184-1191. |

| [6] | 赵海岭, 杨永利, 张忠明, 王天峰, 张一晨, 李笑竹. 区域共同市场绿色电力与绿色证书协同交易模式[J]. 发电技术, 2025, 46(6): 1251-1259. |

| [7] | 路诗梦, 孙建林, 曾凡杰, 林小杰, 吴均湛, 马添翼, 钟崴, 谢立坤, 谢伟. 零碳地热能综合利用技术研究进展[J]. 发电技术, 2025, 46(5): 909-922. |

| [8] | 龙潇, 张晋宾, 陈令特. 未来能源技术展望[J]. 发电技术, 2025, 46(4): 651-693. |

| [9] | 鲁亚楠, 徐涛, 刘泽楠. 制氢系统对双馈风机串补系统次同步振荡特性的影响[J]. 发电技术, 2025, 46(4): 715-726. |

| [10] | 张俊, 蒲天骄, 高文忠, 刘友波, 裴玮, 许沛东, 高天露, 白昱阳. 电力系统智能计算的关键技术及应用展望[J]. 发电技术, 2025, 46(3): 421-437. |

| [11] | 杨博, 张子健. 基于人工智能的可再生能源电解水制氢关键技术及发展前景分析[J]. 发电技术, 2025, 46(3): 482-495. |

| [12] | 刘宿城, 栾李, 李龙, 洪涛, 刘晓东. 基于人工智能的直流微电网大信号稳定性评估方法研究[J]. 发电技术, 2025, 46(3): 496-507. |

| [13] | 郑如意, 杨博, 周率, 蒋林, 李鸿彪, 郜登科. 基于人工智能的质子交换膜燃料电池状态估计及故障诊断[J]. 发电技术, 2025, 46(3): 541-555. |

| [14] | 汪义财, 喻鑫, 于敦喜. 能源植物芦竹燃烧利用研究进展[J]. 发电技术, 2025, 46(3): 570-578. |

| [15] | 侯朗博, 孙昊, 陈衡, 高悦. 基于需求响应与Stackelberg博弈的小区综合能源系统优化调度[J]. 发电技术, 2025, 46(2): 219-230. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||