发电技术 ›› 2024, Vol. 45 ›› Issue (2): 291-298.DOI: 10.12096/j.2096-4528.pgt.23071

董军1, 汤建方1, 臧春城2,3,4, 徐立2,3,4, 王志峰2,3,4

收稿日期:2023-06-30

出版日期:2024-04-30

发布日期:2024-04-29

通讯作者:

臧春城

作者简介:基金资助:Jun DONG1, Jianfang TANG1, Chuncheng ZANG2,3,4, Li XU2,3,4, Zhifeng WANG2,3,4

Received:2023-06-30

Published:2024-04-30

Online:2024-04-29

Contact:

Chuncheng ZANG

Supported by:摘要:

球形接头是抛物面槽式太阳能集热器的关键部件,针对球形接头易发生运转卡涩和导热油泄漏问题,研制了一套球形接头性能测试系统。该测试系统可以实现球形接头在旋转、摆转或旋摆联动模式下,以及在导热油温度达393 ℃和压力达4.1 MPa工况条件下的加速寿命测试。以导热油为传热流体,开展了球形接头在导热油温度为393 ℃和压力为2.3 MPa工况条件,以及温度、压力变化条件下的性能测试研究,分析了球形接头在模拟12年寿命期的扭矩特性和密封性能,验证了该测试系统运行的稳定性和可靠性,并且关键技术参数的控制精度和测量精度满足使用要求,为球形接头的性能评价提供了技术支撑。

中图分类号:

董军, 汤建方, 臧春城, 徐立, 王志峰. 抛物面槽式太阳能集热器球形接头测试系统的研制与应用[J]. 发电技术, 2024, 45(2): 291-298.

Jun DONG, Jianfang TANG, Chuncheng ZANG, Li XU, Zhifeng WANG. Development and Application of Test System for Ball Joints of Parabolic Trough Solar Collector[J]. Power Generation Technology, 2024, 45(2): 291-298.

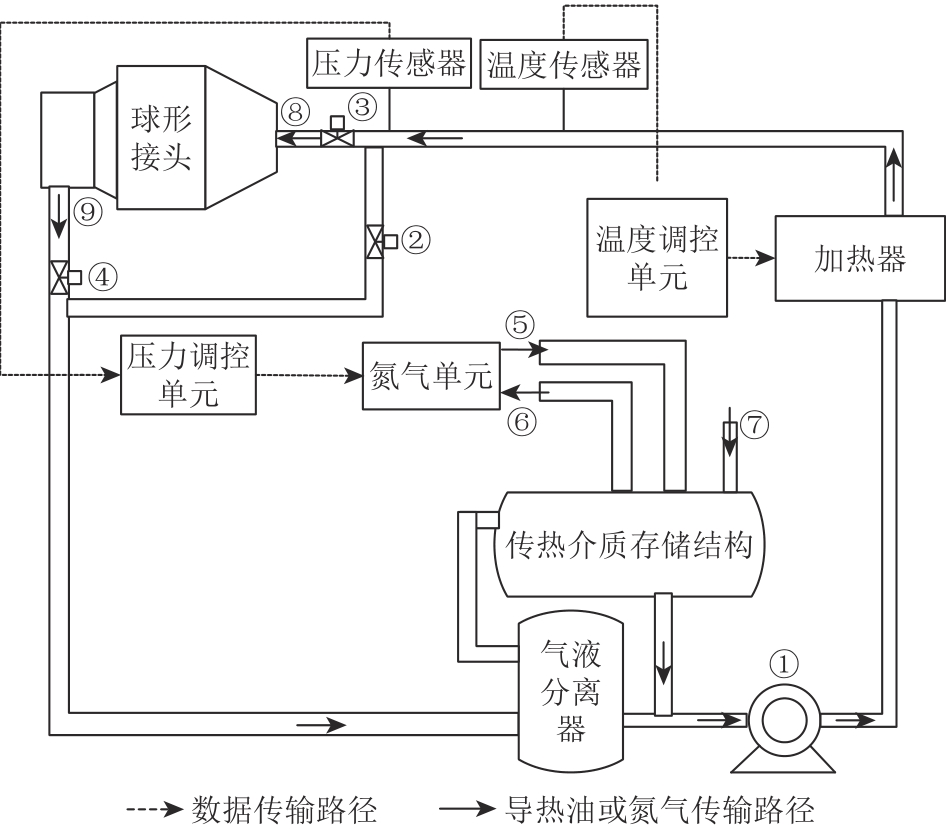

图4 导热油调控装置示意图①—导热油循环泵;②—电动阀门1;③—电动阀门2;④—电动阀门3;⑤—氮气入口;⑥—氮气出口;⑦—注油口;⑧—球形接头入口;⑨—球形接头出口。

Fig. 4 Schematic diagram of heat conduction oil adjustment device

| 类别 | 温度/压力 | |||||

|---|---|---|---|---|---|---|

200 ℃/ 1.0 MPa | 250 ℃/ 1.0 MPa | 293 ℃/ 1.0 MPa | 293 ℃/ 1.7 MPa | 350 ℃/ 2.1 MPa | 393 ℃/ 2.6 MPa | |

| 最大旋转扭矩/(N∙m) | 312.25 | 248.91 | 256.69 | 405.49 | 450.95 | 505.32 |

| 平均旋转扭矩/(N∙m) | 261.37 | 209.46 | 224.16 | 351.53 | 392.20 | 455.60 |

表1 变工况下的球形接头扭矩测试结果

Tab. 1 Torque test results of the ball joint under variable working conditions

| 类别 | 温度/压力 | |||||

|---|---|---|---|---|---|---|

200 ℃/ 1.0 MPa | 250 ℃/ 1.0 MPa | 293 ℃/ 1.0 MPa | 293 ℃/ 1.7 MPa | 350 ℃/ 2.1 MPa | 393 ℃/ 2.6 MPa | |

| 最大旋转扭矩/(N∙m) | 312.25 | 248.91 | 256.69 | 405.49 | 450.95 | 505.32 |

| 平均旋转扭矩/(N∙m) | 261.37 | 209.46 | 224.16 | 351.53 | 392.20 | 455.60 |

| 1 | 王志峰,何雅玲,康重庆,等 .明确太阳能热发电战略定位促进技术发展[J].华电技术,2021,43(11):1-4. |

| WANG Z F, HE Y L, KANG C Q,et al .Strategic positioning of solar thermal power generation to promote technological progress[J].Huadian Technology,2021,43(11):1-4. | |

| 2 | 黄畅,颜逸贤,白尧,等 .促进风电消纳的太阳能-燃煤热电联产系统性能研究[J].中国电力,2022,55(5):182-188. |

| HUANG C, YAN Y X, BAI Y,et al .Performance analysis of solar-coal cogeneration system for wind power consumption[J].Electric Power,2022,55(5):182-188. | |

| 3 | 吴昊文,张乐平,张维,等 .高比例太阳能接入配电终端微电网调峰方法研究[J].电网与清洁能源,2023,39(2):122-127. doi:10.3969/j.issn.1674-3814.2023.02.016 |

| WU H W, ZHANG L P, ZHANG W,et al .A study on peak load regulating methods of high proportion solar energy connected to distribution terminal microgrid[J].Power System and Clean Energy,2023,39(2):122-127. doi:10.3969/j.issn.1674-3814.2023.02.016 | |

| 4 | 梁政,魏震波,孙舟倍,等 .光热发电商参与下的电力现货市场均衡分析[J].电力建设,2022,43(1):122-131. doi:10.12204/j.issn.1000-7229.2022.01.014 |

| LIANG Z, WEI Z B, SUN Z B,et al .Analysis of the equilibrium of electricity spot market with the participation of CSP[J].Electric Power Construction,2022,43(1):122-131. doi:10.12204/j.issn.1000-7229.2022.01.014 | |

| 5 | 王湘艳,陈宁,王维洲,等 .计及置信容量的光热电站储热容量优化配置[J].电力工程技术,2022,41(5):103-109. doi:10.12158/j.2096-3203.2022.05.012 |

| WANG X Y, CHEN N, WANG W Z,et al .Optimal design for thermal energy storage capacity of CSP considering credible capacity[J].Electric Power Engineering Technology,2022,41(5):103-109. doi:10.12158/j.2096-3203.2022.05.012 | |

| 6 | 徐立,孙飞虎,李钧,等 .抛物面槽式太阳能集热器热损失因素研究[J].发电技术,2023,44(2):229-234. doi:10.12096/j.2096-4528.pgt.21070 |

| XU L, SUN F H, LI J,et al .Study on heat loss factors of parabolic trough solar collectors[J].Power Generation Technology,2023,44(2):229-234. doi:10.12096/j.2096-4528.pgt.21070 | |

| 7 | 林达,顾丹青,周宇昊,等 .太阳能有机朗肯循环系统技术经济性分析[J].浙江电力,2022,41(4):14-19. |

| LIN D, GU D Q, ZHOU Y H,et al .Thermo-economic analysis of solar organic Rankine cycle system[J].Zhejiang Electric Power,2022,41(4):14-19. | |

| 8 | 卢乃兵,刘万军,尹航 .高原地区槽式光热电站导热油泄漏监测装置应用研究[J].内蒙古电力技术,2022,40(6):13-16. |

| LU N B, LIU W J, YIN H .Research on application of thermal conductive oil leakage monitoring device in trough photothermal power station in plateau area[J].Inner Mongolia Electric Power,2022,40(6):13-16. | |

| 9 | 丁路,肖欣悦,奚正稳,等 .塔式太阳能吸热器不同方位高空风速模拟计算及影响分析[J].发电技术,2021,42(6):707-714. doi:10.12096/j.2096-4528.pgt.21026 |

| DING L, XIAO X Y, XI Z W,et al .Simulation calculation and influence analysis of high altitude wind speed in different directions of tower solar energy receiver[J].Power Generation Technology,2021,42(6):707-714. doi:10.12096/j.2096-4528.pgt.21026 | |

| 10 | 王志峰 .太阳能热发电站设计[M].2版.北京:化学工业出版社,2019:10-16. doi:10.1016/b978-0-12-815613-1.00003-1 |

| WANG Z F .Design of solar thermal power plants[M].2nd ed.Beijing:Chemical Industry Press,2019:10-16. doi:10.1016/b978-0-12-815613-1.00003-1 | |

| 11 | KRISHNA Y, FAIZAL M, SAIDUR R,et al .State-of-the-art heat transfer fluids for parabolic trough collector[J].International Journal of Heat and Mass Transfer,2020,152:119541. doi:10.1016/j.ijheatmasstransfer.2020.119541 |

| 12 | PAL R K, KUMAR K R .Investigations of thermo-hydrodynamics,structural stability,and thermal energy storage for direct steam generation in parabolic trough solar collector:a comprehensive review[J].Journal of Cleaner Production,2021,311:1-30. doi:10.1016/j.jclepro.2021.127550 |

| 13 | 徐立,孙飞虎,李钧,等 .流量对抛物面槽式太阳能集热器传热特性影响的实验分析[J].发电技术,2021,42(6):665-672. doi:10.12096/j.2096-4528.pgt.21072 |

| XU L, SUN F H, LI J,et al .Experimental analysis of the influence of flow rate on heat transfer characteristics of parabolic trough solar collector[J].Power Generation Technology,2021,42(6):665-672. doi:10.12096/j.2096-4528.pgt.21072 | |

| 14 | 程兴利 .槽式太阳能热发电站中太阳岛的集热器回路的压力试验分析[J].太阳能,2022(1):72-76. |

| CHENG X L .Pressure test analysis of collector loops of solar island in trough solar thermal power station[J].Solar Energy,2022(1):72-76. | |

| 15 | 陈晨,赵雄,于延兴,等 .槽式太阳能集热器跟踪系统故障分析[J].电力安全技术,2022,24(1):18-19. doi:10.3969/j.issn.1008-6226.2022.01.007 |

| CHEN C, ZHAO X, YU Y X,et al .Analysis on a fault of trough solar collector tracking system[J].Electric Safety Technology,2022,24(1):18-19. doi:10.3969/j.issn.1008-6226.2022.01.007 | |

| 16 | 张磊,刘雪莲,王静,等 .槽式太阳能集热管寿命评价分析[J].太阳能,2018(10):52-54. doi:10.3969/j.issn.1003-0417.2018.10.013 |

| ZHANG L, LIU X L, WANG J,et al .Analysis on trough type solar collector tube life assessment[J].Solar Energy,2018(10):52-54. doi:10.3969/j.issn.1003-0417.2018.10.013 | |

| 17 | 皮骏,蒲芋树,刘光才,等 .内置扰流柱列太阳能集热管的换热分析[J].太阳能学报,2020,41(9):227-232. |

| PI J, PU Y S, LIU G C,et al .Heat transfer analysis of internally pin-finned solar parabolic trough collector[J].Acta Energiae Solaris Sinica,2020,41(9):227-232. | |

| 18 | KHANNA S, NEWAR S, SHARMA V,et al .Deformation of receiver in solar parabolic trough collector due to non uniform temperature and solar flux distribution and use of bimetallic absorber tube with multiple supports[J].Energy,2018,165:1078-1088. doi:10.1016/j.energy.2018.09.145 |

| 19 | 王立,张智,施瑶璐,等 .基于数值仿真的抛物槽式太阳能集热器研究进展[J].发电技术,2021,42(6):643-652. doi:10.12096/j.2096-4528.pgt.21061 |

| WANG L, ZHANG Z, SHI Y L,et al .Research progress of parabolic trough solar collector based on numerical simulation[J].Power Generation Technology,2021,42(6):643-652. doi:10.12096/j.2096-4528.pgt.21061 | |

| 20 | HYSPAN C .Summary test report ball joint life cycle test solar plant installations[EB/OL].. |

| 21 | LEON J, CLAVERO J, VALENZUELA L,et al .Test loop for inter-connections of parabolic trough collectors[J].AIP Conference Proceedings,2018,2033(1):030008. doi:10.1063/1.5067024 |

| 22 | MUÑOZ-ANTON J, BIENCINTO M, ZARZA E,et al .Theoretical basis and experimental facility for parabolic trough collectors at high temperature using gas as heat transfer fluid[J].Applied Energy,2014,135:373-381. doi:10.1016/j.apenergy.2014.08.099 |

| 23 | 高启宽,王自发,高勇,等 .槽式太阳能光热发电热工自动装置PID参数整定分析及对策[J].中文科技期刊数据库(文摘版)工程技术,2021(12):307-308. |

| GAO Q K, WANG Z F, GAO Y,et al .PID parameter setting analysis and countermeasure of automatic thermal equipment for parabolic trough solar thermal power[J].Chinese Science and Technology Periodical Database (Abstract Version) Engineering Technology,2021(12):307-308. | |

| 24 | 生态环境部,国家市场监督管理总局 . 挥发性有机物无组织排放控制标准: [S].北京:中国环境出版集团,2019. |

| Ministry of Ecology and Environment of the People’s Republic of China,State Administration for Market Regulation . Standard for fugitive emission of volatile organic compounds: [S].Beijing:China Environmental Science Press,2019. |

| [1] | 徐立, 孙飞虎, 李钧, 张强强. 抛物面槽式太阳能集热器热损失因素研究[J]. 发电技术, 2023, 44(2): 229-234. |

| [2] | 徐运飞, 吴水木, 李英杰. 面向太阳能热发电的CaO-CO2热化学储热技术研究进展[J]. 发电技术, 2022, 43(5): 740-747. |

| [3] | 徐立, 孙飞虎, 李志, 张强强. 一种太阳能集热器流体平均温度计算方法[J]. 发电技术, 2022, 43(3): 405-412. |

| [4] | 廖志荣, 李朋达, 田紫芊, 徐超, 魏高升. 非均匀翅片对级联相变储热系统热性能强化的研究[J]. 发电技术, 2022, 43(1): 83-91. |

| [5] | 丁路, 肖欣悦, 奚正稳, 华文瀚. 塔式太阳能吸热器不同方位高空风速模拟计算及影响分析[J]. 发电技术, 2021, 42(6): 707-714. |

| [6] | 孙浩, 高博, 刘建兴. 塔式太阳能电站定日镜场布局研究[J]. 发电技术, 2021, 42(6): 690-698. |

| [7] | 刘兰华, 狄林文, 董兴万, 王瑞林. 抛物槽式聚光太阳能集热回路动态特性研究[J]. 发电技术, 2021, 42(6): 673-681. |

| [8] | 徐立, 孙飞虎, 李钧, 张强强. 流量对抛物面槽式太阳能集热器传热特性影响的实验分析[J]. 发电技术, 2021, 42(6): 665-672. |

| [9] | 刘兰华, 王瑞林, 洪慧. 塔式太阳能辅助燃气蒸汽联合循环钙基碳捕集系统设计[J]. 发电技术, 2021, 42(4): 517-524. |

| [10] | 王泽众, 黄平瑞, 魏高升, 崔柳, 徐超, 杜小泽. 太阳能热发电固–气两相化学储热技术研究进展[J]. 发电技术, 2021, 42(2): 238-246. |

| [11] | 刘尧东, 张燕平, 万亮, 高伟. 基于Al2O3纳米流体的槽式太阳能热发电集热器传热建模及性能分析[J]. 发电技术, 2021, 42(2): 230-237. |

| [12] | 郑开云. 超临界二氧化碳循环发电技术应用[J]. 发电技术, 2020, 41(4): 399-406. |

| [13] | 张哲旸,巨星,潘信宇,杨宇,徐超,杜小泽. 太阳能光伏-光热复合发电技术及其商业化应用[J]. 发电技术, 2020, 41(3): 220-230. |

| [14] | 佟锴,杨立军,宋记锋,杜小泽,杨勇平. 聚光太阳能集热场先进技术综述[J]. 发电技术, 2019, 40(5): 413-425. |

| [15] | 布鲁斯·安德森,黄湘,孙海翔,王福华. 新型布雷登塔式太阳能热发电系统[J]. 发电技术, 2018, 39(1): 37-42. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||