发电技术 ›› 2025, Vol. 46 ›› Issue (1): 190-199.DOI: 10.12096/j.2096-4528.pgt.23126

• 发电及环境保护 • 上一篇

曾宪民, 李柏云, 沈向阳, 陈嘉澍, 丁力行

收稿日期:2023-12-21

修回日期:2024-03-05

出版日期:2025-02-28

发布日期:2025-02-27

通讯作者:

沈向阳

作者简介:基金资助:Xianmin ZENG, Boyun LI, Xiangyang SHEN, Jiashu CHEN, Lixing DING

Received:2023-12-21

Revised:2024-03-05

Published:2025-02-28

Online:2025-02-27

Contact:

Xiangyang SHEN

Supported by:摘要:

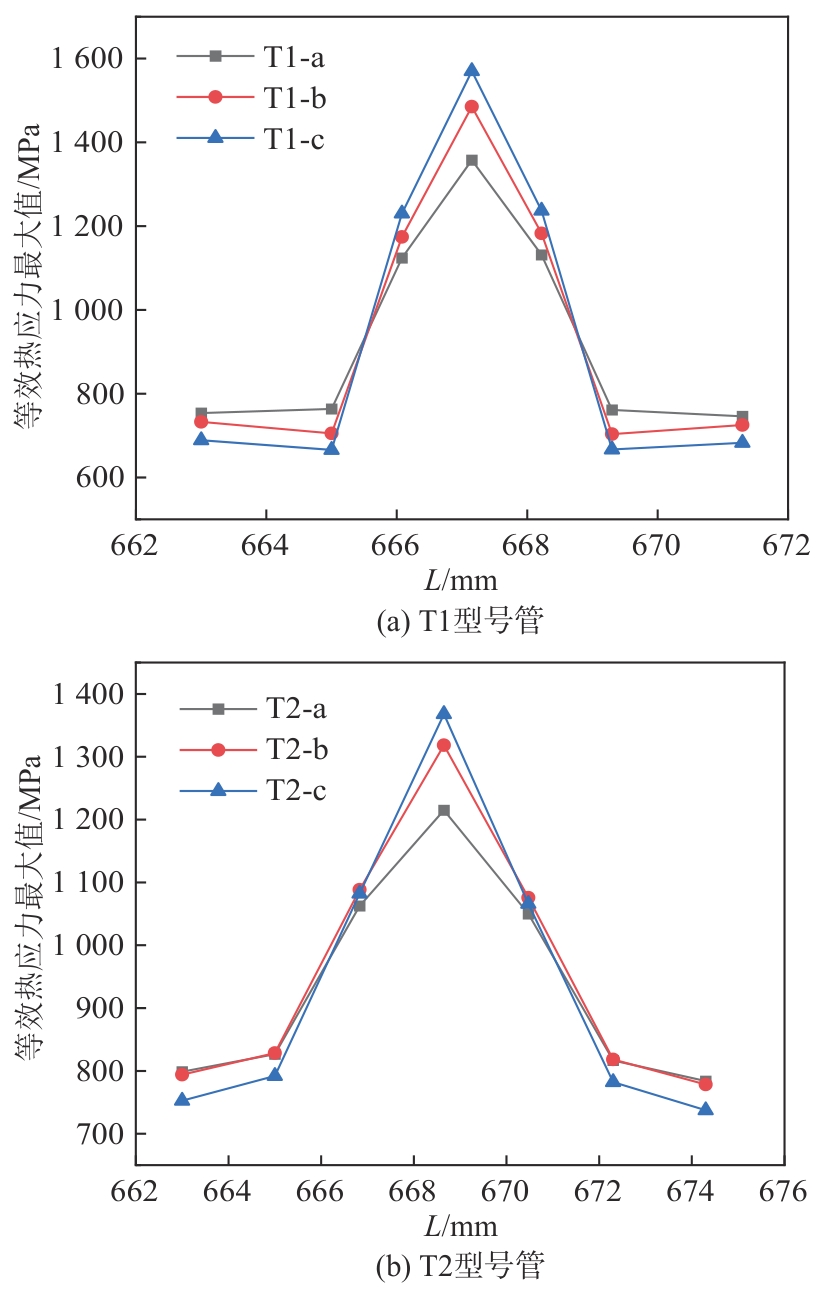

目的 在日常运行中,太阳能吸热器管面外壁内外侧热流密度高低不均,导致管壁温分布不均匀、梯度变化大,易产生较高的热应力,从而使吸热管发生变形甚至结构损伤失效。为此,对柱式吸热器中吸热管所受热应力开展了研究。 方法 采用Ansys中Design Modeler建立吸热管的三维模型,利用Mesh进行网格划分,然后用Fluent对半周受热下吸热管热应力进行数值模拟。 结果 横纹管在半周受热方式下,高热流密度侧管外壁的热应力最大,高低热流密度受热面的交界处管壁热应力最小。横纹管凹槽处的热应力值大于光滑段,槽宽相同时,槽深越大,横纹管凹槽段的等效热应力最大值越大;槽深相同时,槽宽越大,横纹管等效热应力最大值越小。横纹管的等效热应力最大值随熔盐进口温度的升高而增大,随熔盐进口流速的增大而减小。 结论 通过热应力分析可知热流密度、槽深、槽宽、进口温度和进口流速对横纹管所受热应力大小的影响规律,对延长柱式吸热器的使用寿命具有重要意义。

中图分类号:

曾宪民, 李柏云, 沈向阳, 陈嘉澍, 丁力行. 半周受热下太阳能吸热器横纹管的热应力分析[J]. 发电技术, 2025, 46(1): 190-199.

Xianmin ZENG, Boyun LI, Xiangyang SHEN, Jiashu CHEN, Lixing DING. Thermal Stress Analysis of Transversally Corrugated Tube in Solar Receiver Under Semi-Circumference Heating[J]. Power Generation Technology, 2025, 46(1): 190-199.

| 密度/(kg/m3) | 定压比热容/[J/(kg⋅℃)] | 导热系数/[W/(m⋅℃)] | 弹性模量/GPa | 泊松比 | 热膨胀系数/ ℃-1 |

|---|---|---|---|---|---|

| 7 980 | 502 | 18.4 | 193 | 0.305 | 1.4×10-4 |

表1 不锈钢316L的物性参数

Tab. 1 Physical properties of stainless steel 316L

| 密度/(kg/m3) | 定压比热容/[J/(kg⋅℃)] | 导热系数/[W/(m⋅℃)] | 弹性模量/GPa | 泊松比 | 热膨胀系数/ ℃-1 |

|---|---|---|---|---|---|

| 7 980 | 502 | 18.4 | 193 | 0.305 | 1.4×10-4 |

| 横纹管 | 槽宽P1/mm | 槽深e/mm |

|---|---|---|

| 1号管(T1-a) | 4.3 | 0.45 |

| 2号管(T1-b) | 4.3 | 0.70 |

| 3号管(T1-c) | 4.3 | 0.95 |

| 4号管(T2-a) | 7.3 | 0.45 |

| 5号管(T2-b) | 7.3 | 0.70 |

| 6号管(T2-c) | 7.3 | 0.95 |

表2 横纹管的槽宽和槽深参数

Tab. 2 Parameters of groove width and groove depth for transversally corrugated tubes

| 横纹管 | 槽宽P1/mm | 槽深e/mm |

|---|---|---|

| 1号管(T1-a) | 4.3 | 0.45 |

| 2号管(T1-b) | 4.3 | 0.70 |

| 3号管(T1-c) | 4.3 | 0.95 |

| 4号管(T2-a) | 7.3 | 0.45 |

| 5号管(T2-b) | 7.3 | 0.70 |

| 6号管(T2-c) | 7.3 | 0.95 |

图8 不同结构横纹管一个节距各截面的等效热应力最大值

Fig. 8 Maximum values of equivalent thermal stress in cross-section at a pitch for differently structured transversally corrugated tubes

| 1 | 丁路,肖欣悦,奚正稳,等 .塔式太阳能吸热器不同方位高空风速模拟计算及影响分析[J].发电技术,2021,42(6):707-714. doi:10.12096/j.2096-4528.pgt.21026 |

| DING L, XIAO X Y, XI Z W,et al .Simulation calculation and influence analysis of high altitude wind speed in different directions of tower solar energy receiver[J].Power Generation Technology,2021,42(6):707-714. doi:10.12096/j.2096-4528.pgt.21026 | |

| 2 | 王晓文,屠楠,方嘉宾,等 .布置螺旋管的太阳能腔式吸热器光学性能模拟[J].发电技术,2023,44(2):221-228. doi:10.12096/j.2096-4528.pgt.22120 |

| WANG X W, TU N, FANG J B,et al .Simulation of optical performance for a solar cavity receiver arranged with spiral tubes[J].Power Generation Technology,2023,44(2):221-228. doi:10.12096/j.2096-4528.pgt.22120 | |

| 3 | 郑建涛,严俊杰,韩临武,等 .多点聚焦的太阳能柱式吸热器能流分布研究[J].中国电机工程学报,2015,35(11):2796-2803. doi:10.13334/j.0258-8013.pcsee.2015.11.018 |

| ZHENG J T, YAN J J, HAN L W,et al .Analysis of the solar thermal cylinder receiver heat flux distribution under multi-aiming point strategy[J].Proceedings of the CSEE,2015,35(11):2796-2803. doi:10.13334/j.0258-8013.pcsee.2015.11.018 | |

| 4 | 张淳,王富强,谭建宇,等 .汇聚太阳能流体流速对吸热器温度场和应力场影响[J].节能技术,2015,33(2):103-107. doi:JournalArticle/5b3b9cd3c095d70f0081dfbe |

| ZHANG C, WANG F Q, TAN J Y,et al .Effects of fluid velocity on temperature and thermal stress field of tube receiver under concentrated solar irradiation[J].Energy Conservation Technology,2015,33(2):103-107. doi:JournalArticle/5b3b9cd3c095d70f0081dfbe | |

| 5 | 王振,马洪芳,孟扬,等 .太阳能有机朗肯循环发电系统分析[J].节能技术,2014,32(5):397-403. doi:10.3969/j.issn.1002-6339.2014.05.003 |

| WANG Z, MA H F, MENG Y,et al .Analysis for solar power generation system of organic Rankine cycle[J].Energy Conservation Technology,2014,32(5):397-403. doi:10.3969/j.issn.1002-6339.2014.05.003 | |

| 6 | 李嘉宝,王沛,赵亮 .基于分布参数模型的塔式熔盐吸热器换热过程动态特性研究[J].可再生能源,2018,36(7):991-996. doi:10.3969/j.issn.1671-5292.2018.07.007 |

| LI J B, WANG P, ZHAO L .Study on dynamic characteristics of heat exchange process of a tower type molten salt receiver based on distributed parameter model[J].Renewable Energy Resources,2018,36(7):991-996. doi:10.3969/j.issn.1671-5292.2018.07.007 | |

| 7 | CONROY T, COLLINS M N, FISHER J,et al .Thermohydraulic analysis of single phase heat transfer fluids in CSP solar receivers[J].Renewable Energy,2018,129:150-167. doi:10.1016/j.renene.2018.05.101 |

| 8 | 蔡德程,芮明奇,关欣,等 .高温太阳能吸热管在非均匀热流下的温度研究及结构优化[J].太阳能学报,2022,43(1):437-442. |

| CAI D C, RUI M Q, GUAN X,et al .Temperature study and structural optimization of high temperature solar absorbing tube by non-uniform heat flux[J].Acta Energiae Solaris Sinica,2022,43(1):437-442. | |

| 9 | RODRÍGUEZ-SÁNCHEZ M R, MARUGÁN-CRUZ C, ACOSTA-IBORRA A,et al .Thermo-mechanical modelling of solar central receivers:effect of incident solar flux resolution[J].Solar Energy,2018,165:43-54. doi:10.1016/j.solener.2018.03.005 |

| 10 | 沈向阳,丁静,陆建峰 .半周加热横纹管内熔盐强化传热特性[J].化工学报,2019,70(12):4546-4555. doi:10.11949/0438-1157.20190685 |

| SHEN X Y, DING J, LU J F .Heat transfer characteristic of molten salt in transverse corrugated tube with semi-circumference heating[J].CIESC Journal,2019,70(12):4546-4555. doi:10.11949/0438-1157.20190685 | |

| 11 | 张沧洪,屠楠,方嘉宾 .单侧非均匀热流边界下水/蒸汽太阳能吸热管热应力研究[J].发电技术,2021,42(6):699-706. doi:10.12096/j.2096-4528.pgt.21047 |

| ZHANG C H, TU N, FANG J B .Study on thermal stress of water/steam solar absorber tubes under unilateral non-uniform heat flux boundary conditions[J].Power Generation Technology,2021,42(6):699-706. doi:10.12096/j.2096-4528.pgt.21047 | |

| 12 | WANG W Q, LI M J, CHENG Z D,et al .Coupled optical-thermal-stress characteristics of a multi-tube external molten salt receiver for the next generation concentrating solar power[J].Energy,2021,233:121110. doi:10.1016/j.energy.2021.121110 |

| 13 | FANG J, ZHANG C, TU N,et al .Numerical investigation on heat transfer and thermoelastic stress in a solar cavity receiver[J].Applied Thermal Engineering,2021,198:117430. doi:10.1016/j.applthermaleng.2021.117430 |

| 14 | DU B C, HE Y L, ZHENG Z J,et al .Analysis of thermal stress and fatigue fracture for the solar tower molten salt receiver[J].Applied Thermal Engineering,2016,99:741-750. doi:10.1016/j.applthermaleng.2016.01.101 |

| 15 | ZHENG Z J, LI M J, HE Y L .Thermal analysis of solar central receiver tube with porous inserts and non-uniform heat flux[J].Applied Energy,2017,185:1152-1161. doi:10.1016/j.apenergy.2015.11.039 |

| 16 | 沈向阳,丁静,陆建峰 .轴向非均匀热流下熔盐吸热管的传热特性[J].当代化工,2015,44(8):1965-1968. doi:10.3969/j.issn.1671-0460.2015.08.078 |

| SHEN X Y, DING J, LU J F .Heat transfer performance of molten salts in receiver tube with axial nonuniform heat flux[J].Contemporary Chemical Industry,2015,44(8):1965-1968. doi:10.3969/j.issn.1671-0460.2015.08.078 | |

| 17 | 杨敏林,杨晓西,丁静,等 .半周加热半周绝热的熔盐吸热管传热特性研究[J].太阳能学报,2009,30(8):1007-1012. doi:10.3321/j.issn:0254-0096.2009.08.001 |

| YANG M L, YANG X X, DING J,et al .Heat transfer research on molten salt receiver with semi-circumference heat[J].Acta Energiae Solaris Sinica,2009,30(8):1007-1012. doi:10.3321/j.issn:0254-0096.2009.08.001 | |

| 18 | FLORES O, MARUGÁN-CRUZ C, SANTANA D,et al .Thermal stresses analysis of a circular tube in a central receiver[J].Energy Procedia,2014,49:354-362. doi:10.1016/j.egypro.2014.03.038 |

| 19 | LU J, SHEN X, DING J,et al .Convective heat transfer of high temperature molten salt in transversely grooved tube[J].Applied Thermal Engineering,2013,61(2):157-162. doi:10.1016/j.applthermaleng.2013.07.037 |

| 20 | 沈向阳,陆建峰,丁静,等 .熔盐在螺旋槽管和横纹管内强化传热特性[J].工程热物理学报,2013,34(6):1149-1152. |

| SHEN X Y, LU J F, DING J,et al .Heat transfer enhancement of molten salt in spirally corrugated tube and transversely corrugated tube[J].Journal of Engineering Thermophysics,2013,34(6):1149-1152. |

| [1] | 李凯, 章平衡, 孟志浩, 曹允宁, 徐尧, 刘莉, 李廉明. SCR外置烟道飞灰沉积特性与流场优化数值仿真[J]. 发电技术, 2025, 46(1): 145-153. |

| [2] | 王凯卉, 刘斌, 折晓会, 刘伟, 范昊, 康宗耀, 徐礼. 氨氢混合燃烧在旋流燃烧器中的动力学特性与NO x 减排机理研究[J]. 发电技术, 2025, 46(1): 171-179. |

| [3] | 刘卓, 陈冬林, 汪淑奇, 杨仪江, 闫优洋, 杨展. 减缓脱硫塔除雾器堵塞的流场优化方法[J]. 发电技术, 2024, 45(6): 1087-1094. |

| [4] | 邱立翔, 黄超, 魏高升, 崔柳, 杜小泽. 颗粒团聚对太阳盐纳米流体导热性能的影响特性研究[J]. 发电技术, 2024, 45(5): 878-887. |

| [5] | 屠楠, 刘家琛, 徐静, 方嘉宾, 马彦花. 管壳式相变蓄热器的蓄释热过程性能分析[J]. 发电技术, 2024, 45(3): 508-516. |

| [6] | 刘学, 李国栋, 张瑞颖, 侯一晨, 陈磊, 杨立军. 电站空冷岛轴流风机模型研究[J]. 发电技术, 2024, 45(3): 545-557. |

| [7] | 龚思琦, 云再鹏, 许明, 敖乐, 李初福, 黄凯, 孙晨. 基于三元催化剂的固体氧化物燃料电池尾气催化燃烧数值模拟[J]. 发电技术, 2024, 45(2): 331-340. |

| [8] | 杨旸, 李耀强, 张金琦. 基于数值方法的燃气轮机贫预混旋流燃烧室单头部结构设计[J]. 发电技术, 2023, 44(5): 712-721. |

| [9] | 杨旸, 郭德三, 李耀强, 张金琦. 燃气轮机贫预混多旋流组合燃烧室头部结构设计[J]. 发电技术, 2023, 44(2): 183-192. |

| [10] | 刘文斌, 李璐璐, 李晓金, 姚宣, 杨海瑞. 脱硫湿烟气喷淋冷凝过程中的参数优化研究[J]. 发电技术, 2023, 44(1): 107-114. |

| [11] | 吴荣辉, 刘冬, 郁冶, 牟凯龙, 赵兰浩. 基于浸入边界法的海上风电双向流固耦合数值模拟方法[J]. 发电技术, 2023, 44(1): 44-52. |

| [12] | 张弘毅, 曲立涛. 9F级燃机选择性催化还原脱硝数值模拟研究与应用[J]. 发电技术, 2023, 44(1): 78-84. |

| [13] | 张泽栋, 王维, 叶季蕾, 申洪. 储热型太阳能光热发电稳态功率模型[J]. 发电技术, 2022, 43(5): 731-739. |

| [14] | 李泽航, 周浩, 李浩秒, 王康丽, 蒋凯. 面向电力系统的液态金属电池储能技术[J]. 发电技术, 2022, 43(5): 760-774. |

| [15] | 孔文俊, 张艳森, 汤效平, 张伟阔. 大容量储能锂电池电芯产热特性研究[J]. 发电技术, 2022, 43(5): 801-809. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||