发电技术 ›› 2022, Vol. 43 ›› Issue (5): 801-809.DOI: 10.12096/j.2096-4528.pgt.22135

孔文俊1, 张艳森1, 汤效平2, 张伟阔2

收稿日期:2022-08-15

出版日期:2022-10-31

发布日期:2022-11-04

作者简介:基金资助:Wenjun KONG1, Yansen ZHANG1, Xiaoping TANG2, Weikuo ZHANG2

Received:2022-08-15

Published:2022-10-31

Online:2022-11-04

Supported by:摘要:

研究大容量储能锂电池电芯的产热特性对于锂电池储能热管理设计有重要意义。采用实验方法测量了电芯的导热系数、比热、电芯在充电和放电过程的绝热温度特性,建立了考虑电芯内部的热传导、电芯表面与空气的自然对流换热的传热模型。数值模拟获得了充电和放电过程中电池最后达到的最高温度、最大温升随着充放电倍率变化的规律,电芯表面温度随时间的变化规律,电芯之间的最佳间距,以及冷却进风量随进风温度变化的规律。结果表明,大容量储能锂电池充电过程产热量略高于放电过程产热量。

中图分类号:

孔文俊, 张艳森, 汤效平, 张伟阔. 大容量储能锂电池电芯产热特性研究[J]. 发电技术, 2022, 43(5): 801-809.

Wenjun KONG, Yansen ZHANG, Xiaoping TANG, Weikuo ZHANG. Study on Heat Production Characteristics of Lithium-ion Batteries for Large Capacity Energy Storage[J]. Power Generation Technology, 2022, 43(5): 801-809.

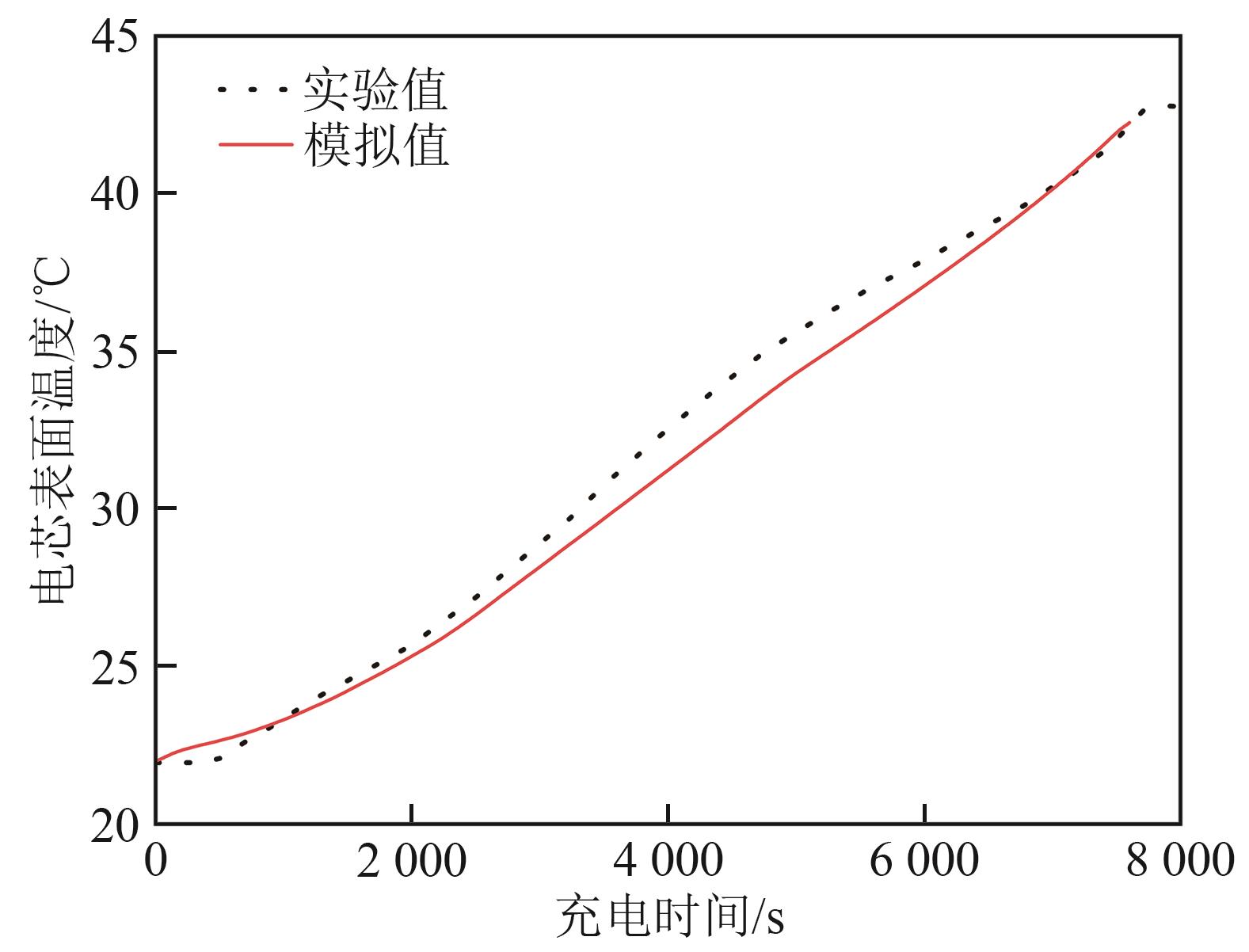

图1 在0.5 C充电、22 ℃下的实验与仿真温度值对比

Fig. 1 Comparison of temperature between experiment and simulation under the condition of 0.5 C charging with ambient temperature of 22 ℃

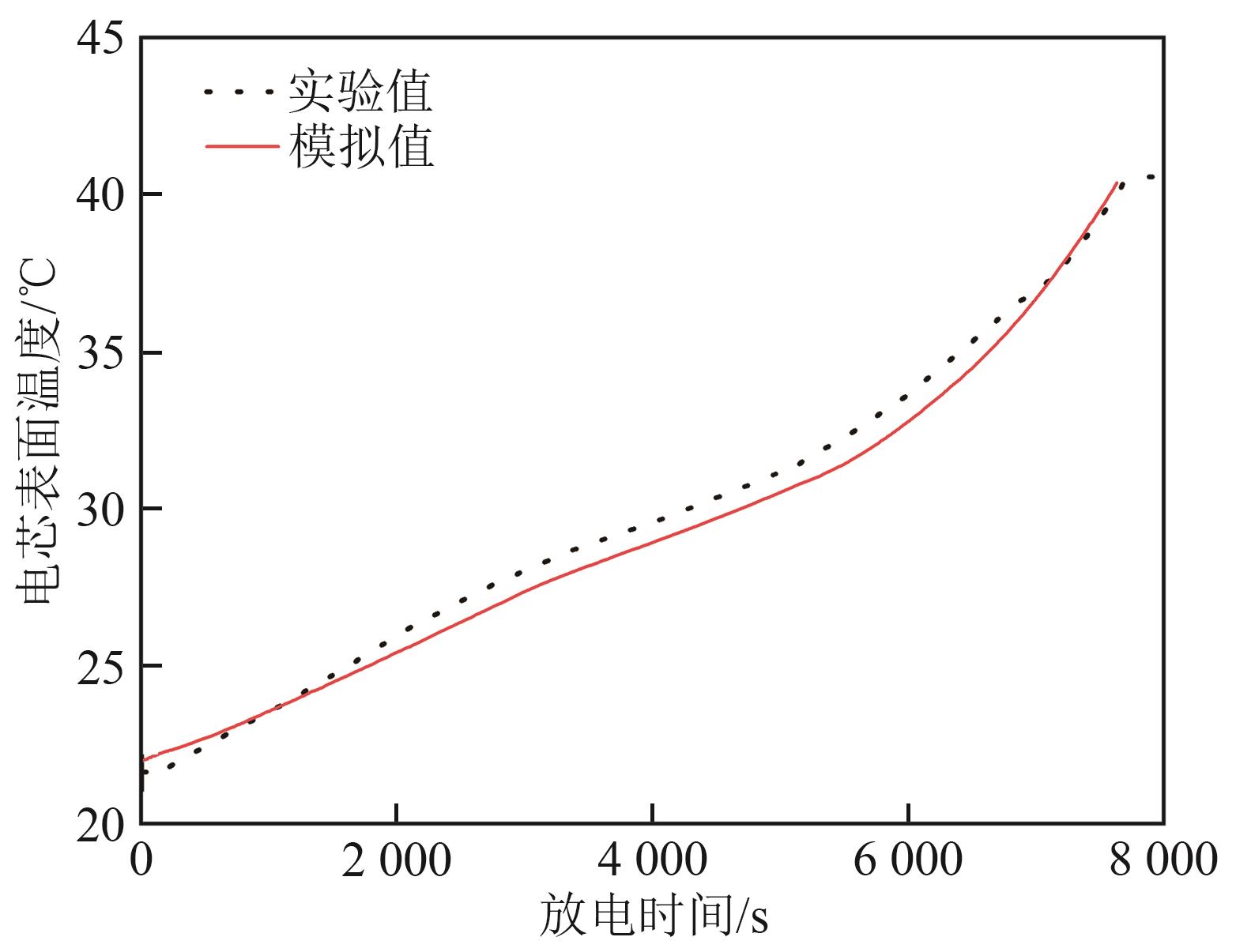

图2 在0.5 C放电、22 ℃下的实验与仿真温度值对比

Fig. 2 Comparison of temperature between experiment and simulation under the condition of 0.5 C discharging with ambient temperature of 22 ℃

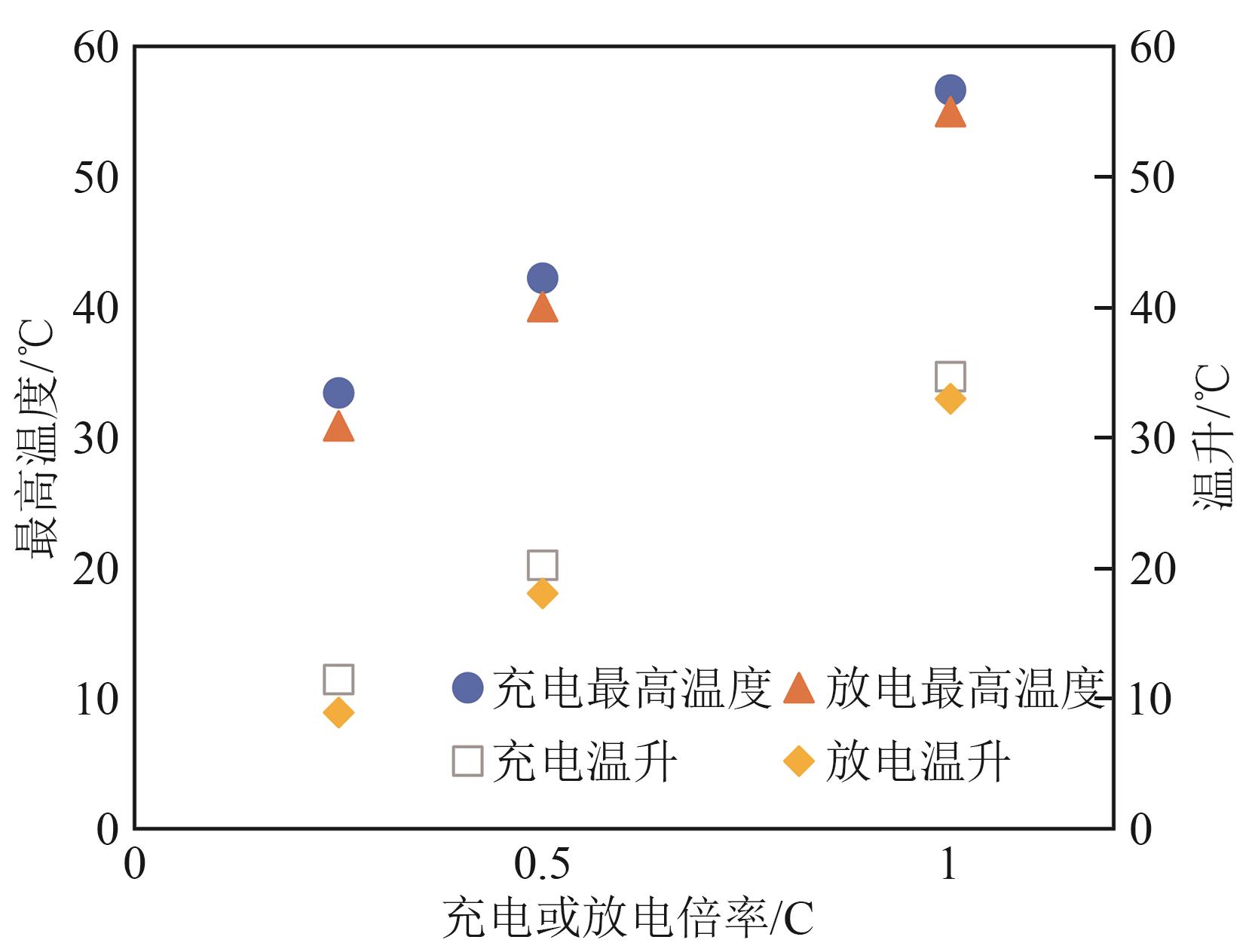

图5 充电或放电过程结束时电池的最高温度和温升随充电或放电倍率的变化关系

Fig. 5 Change relationship between the maximum temperature and temperature rise of the cell at the end of the charging or discharging process and the charging or discharging rates

| 1 | 李建林,李雅欣,周喜超 .电网侧储能技术研究综述[J].电力建设,2020,41(6):77-84. doi:10.16628/j.cnki.2095-8188.2020.05.001 |

| LI J L, LI Y X, ZHOU X C .Summary of research on grid-side energy storage technology[J].Electric Power Construction,2020,41(6):77-84. doi:10.16628/j.cnki.2095-8188.2020.05.001 | |

| 2 | 王悦,林健,张仪,等 .储能装置抑制电网功率振荡的参数优化设计[J].智慧电力,2020,48(8):76-83. |

| WANG Y, LIN J, ZHANG Y,et al .Parameter optimization design of energy storage devices to suppress power system oscillation[J].Smart Power,2020,48(8):76-83. | |

| 3 | HE F, LI X, MA L .Combined experimental and numerical study of thermal management of battery module consisting of multiple Li-ion cells[J].International Journal of Heat and Mass Transfer,2014,72:622-629. doi:10.1016/j.ijheatmasstransfer.2014.01.038 |

| 4 | CHO G Y, CHOI J W, PARK J H,et al .Transient modeling and validation of lithium ion battery pack with air cooled thermal management system for electric vehicles[J].International Journal of Automotive Technology,2014,15:795-803. doi:10.1007/s12239-014-0083-x |

| 5 | 吕超,张爽,朱世怀,等 .储能锂离子电池包强制风冷系统热仿真分析与优化[J].电力系统保护与控制,2021,49(12):48-55. doi:10.19783/j.cnki.pspc.201653 |

| LÜ C, ZHANG S, ZHU S H,et al .Thermal simulation analysis and optimization of forced air cooling system for energy storage lithium-ion battery pack[J].Power System Protection and Control,2021,49(12):48-55. doi:10.19783/j.cnki.pspc.201653 | |

| 6 | 王泽旭,李冰辰,许瑶,等 .基于过冷相变材料热开关的锂离子电池热管理系统[J].发电技术,2022,43(2):328-340. doi:10.12096/j.2096-4528.pgt.21058 |

| WANG Z X, LI B C, XU Y,et al .Lithium-ion battery thermal management system based on the combination of supercooled phase change material and thermal switch[J].Power Generation Technology,2022,43(2):328-340. doi:10.12096/j.2096-4528.pgt.21058 | |

| 7 | SMITH J, HINTERBERGER M, HABLE P,et al . Simulative method for determining the optimal operating conditions for a cooling plate for lithium-ion battery cell modules[J].Journal of Power Sources, 2014, 267: 784-792. doi:10.1016/j.jpowsour.2014.06.001 |

| 8 | QIAN Z, LI Y, RAO Z .Thermal performance of lithium-ion battery thermal management system by using mini-channel cooling[J].Energy Conversion and Management, 2016,126:622-631. doi:10.1016/j.enconman.2016.08.063 |

| 9 | FATHABADI H .High thermal performance lithium-ion battery pack including hybrid active passive thermal management system for using in hybrid/electric vehicles[J].Energy,2014,70:529-538. doi:10.1016/j.energy.2014.04.046 |

| 10 | RAO Z, WANG Q, HUANG C .Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system[J].Applied Energy,2016,164:659-669. doi:10.1016/j.apenergy.2015.12.021 |

| 11 | HUSSAIN A, TSO C Y, CHAO C Y H .Experimental investigation of a passive thermal management system for high-powered lithium ion batteries using nickel foam-paraffin composite[J].Energy,2016,115:209-218. doi:10.1016/j.energy.2016.09.008 |

| 12 | 田刚领,张柳丽,牛哲荟,等 .集装箱式储能系统热管理设计[J].电源技术,2021,45(3):317-319. doi:10.3969/j.issn.1002-087X.2021.03.012 |

| TIAN G L, ZHANG L L, NIU Z H,et al .Design of thermal management for container-type energy storage system[J].Chinese Journal of Power Sources,2021,45(3):317-319. doi:10.3969/j.issn.1002-087X.2021.03.012 | |

| 13 | PESARAN A A .Battery thermal models for hybrid vehicle simulations[J].Journal of Power Sources, 2002,110:377-382. doi:10.1016/s0378-7753(02)00200-8 |

| 14 | SAW L H, YE Y, YEW M C,et al .Computational fluid dynamics simulation on open cell aluminium foams for Li-ion battery cooling system[J].Applied Energy, 2017,204:1489-1499. doi:10.1016/j.apenergy.2017.04.022 |

| 15 | SUN H, WANG X, TOSSAN B,et al .Three-dimensional thermal modeling of a lithium-ion battery pack[J].Journal of Power Sources,2012,206:349-356. doi:10.1016/j.jpowsour.2012.01.081 |

| 16 | SUN H, DIXON R .Development of cooling strategy for an air cooled lithium-ion battery pack[J].Journal of Power Sources,2014,272:404-414. doi:10.1016/j.jpowsour.2014.08.107 |

| 17 | LU Z, YU X, WEI L,et al .Parametric study of forced air cooling strategy for lithium-ion battery pack with staggered arrangement[J].Applied Thermal Engineering,2018,136:28-40. doi:10.1016/j.applthermaleng.2018.02.080 |

| 18 | SHAHID S, AGELIN-CHAAB M .Experimental and numerical studies on air cooling and temperature uniformity in a battery pack[J].International Journal of Energy Research,2018,42:2246-2462. doi:10.1002/er.4018 |

| 19 | HONG S, ZHANG X, CHEN K,et al .Design of flow configuration for parallel air cooled battery thermal management system with secondary vent[J].International Journal of Heat and Mass Transfer,2018,116:1204-1212. doi:10.1016/j.ijheatmasstransfer.2017.09.092 |

| 20 | PARK H .A design of air flow configuration for cooling lithium ion battery in hybrid electric vehicles[J].Journal of Power Sources,2013,239:30-36. doi:10.1016/j.jpowsour.2013.03.102 |

| 21 | CHEN K, WANG S, SONG M,et al .Structure optimization of parallel air-cooled battery thermal management system[J].International Journal of Heat and Mass Transfer,2017,111:943-952. doi:10.1016/j.ijheatmasstransfer.2017.04.026 |

| 22 | CHEN K, SONG M, WEI W,et al .Structure optimization of parallel air-cooled battery thermal management system with U-type flow for cooling efficiency improvement[J].Energy,2018,145:603-613. doi:10.1016/j.energy.2017.12.110 |

| 23 | 白帆飞,陈明彪,宋文吉,等 .锂离子电池组风冷结构设计与优化[J].新能源进展,2016,4(5):358-363. |

| BAI F F, CHEN M B, SONG W J, et al .Design and optimization of air-cooled structure for lithium-ion battery pack[J].Advances in New and Renewable Energy,2016,4(5):358-363. | |

| 24 | XIE J, GE Z, ZANG M,et al .Structural optimization of lithium-ion battery pack with forced air cooling system[J].Applied Thermal Engineering, 2017,126:583-593. doi:10.1016/j.applthermaleng.2017.07.143 |

| 25 | SEVERINO B, GANA F, PALMA-BEHNKE R,et al .Multi-objective optimal design of lithium-ion battery packs based on evolutionary algorithms[J].Journal of Power Sources,2014,267:288-299. doi:10.1016/j.jpowsour.2014.05.088 |

| 26 | CHEN K, WANG S, SONG M,et al .Configuration optimization of battery pack in parallel air-cooled battery thermal management system using an optimization strategy[J].Applied Thermal Engineering,2017, 123:177-186. doi:10.1016/j.applthermaleng.2017.05.060 |

| 27 | CHEN K, WU X, YUAN F,et al .Cooling efficiency improvement of air-cooled battery thermal management system through designing the flow pattern[J].Energy,2019,167:781-790. doi:10.1016/j.energy.2018.11.011 |

| 28 | BERNARDI D, PAWLIKOWSKI E, NEWMAN J .A general energy balance for battery systems[J].Journal of the Electrochemical Society,1985,132(1):5-12. doi:10.1149/1.2113792 |

| 29 | DONG T, PENG P, JIANG F .Numerical modeling and analysis of the thermal behavior of NCM lithium-ion batteries subjected to very high C-rate discharge/charge operations[J].International Journal of Heat and Mass Transfer,2018,117:261-272. doi:10.1016/j.ijheatmasstransfer.2017.10.024 |

| [1] | 屠楠, 刘家琛, 徐静, 方嘉宾, 马彦花. 管壳式相变蓄热器的蓄释热过程性能分析[J]. 发电技术, 2024, 45(3): 508-516. |

| [2] | 刘学, 李国栋, 张瑞颖, 侯一晨, 陈磊, 杨立军. 电站空冷岛轴流风机模型研究[J]. 发电技术, 2024, 45(3): 545-557. |

| [3] | 龚思琦, 云再鹏, 许明, 敖乐, 李初福, 黄凯, 孙晨. 基于三元催化剂的固体氧化物燃料电池尾气催化燃烧数值模拟[J]. 发电技术, 2024, 45(2): 331-340. |

| [4] | 高德扬, 蒋中一, 张锴, 孟境辉. 基于相变材料的半导体热电发电器性能优化研究[J]. 发电技术, 2023, 44(6): 842-849. |

| [5] | 杨旸, 李耀强, 张金琦. 基于数值方法的燃气轮机贫预混旋流燃烧室单头部结构设计[J]. 发电技术, 2023, 44(5): 712-721. |

| [6] | 杨旸, 郭德三, 李耀强, 张金琦. 燃气轮机贫预混多旋流组合燃烧室头部结构设计[J]. 发电技术, 2023, 44(2): 183-192. |

| [7] | 刘文斌, 李璐璐, 李晓金, 姚宣, 杨海瑞. 脱硫湿烟气喷淋冷凝过程中的参数优化研究[J]. 发电技术, 2023, 44(1): 107-114. |

| [8] | 吴荣辉, 刘冬, 郁冶, 牟凯龙, 赵兰浩. 基于浸入边界法的海上风电双向流固耦合数值模拟方法[J]. 发电技术, 2023, 44(1): 44-52. |

| [9] | 张弘毅, 曲立涛. 9F级燃机选择性催化还原脱硝数值模拟研究与应用[J]. 发电技术, 2023, 44(1): 78-84. |

| [10] | 王泽旭, 贺可寒, 孙晨, 李凯璇, 巨星. 采用相变热开关的软包电池热管理研究[J]. 发电技术, 2022, 43(5): 810-822. |

| [11] | 王泽旭, 李冰辰, 许瑶, 刘倩, 李凯璇, 巨星. 基于过冷相变材料热开关的锂离子电池热管理系统[J]. 发电技术, 2022, 43(2): 328-340. |

| [12] | 廖志荣, 李朋达, 田紫芊, 徐超, 魏高升. 非均匀翅片对级联相变储热系统热性能强化的研究[J]. 发电技术, 2022, 43(1): 83-91. |

| [13] | 戴春喜, 梁平, 车德勇, 刘海婷. 蜂窝管湿式电除尘器内部流动特性研究[J]. 发电技术, 2022, 43(1): 155-159. |

| [14] | 高垚楠, 陈海峰, 王建永. 一种新型CO2工质冷热电联供系统的热力性分析[J]. 发电技术, 2022, 43(1): 131-138. |

| [15] | 王立, 张智, 施瑶璐, 徐超, 孙杰. 基于数值仿真的抛物槽式太阳能集热器研究进展[J]. 发电技术, 2021, 42(6): 643-652. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||