发电技术 ›› 2022, Vol. 43 ›› Issue (1): 92-101.DOI: 10.12096/j.2096-4528.pgt.21056

蔡肖, 徐阳, 杨超, 郑章靖

收稿日期:2021-05-13

出版日期:2022-02-28

发布日期:2022-03-18

作者简介:基金资助:Xiao CAI, Yang XU, Chao YANG, Zhangjing ZHENG

Received:2021-05-13

Published:2022-02-28

Online:2022-03-18

Supported by:摘要:

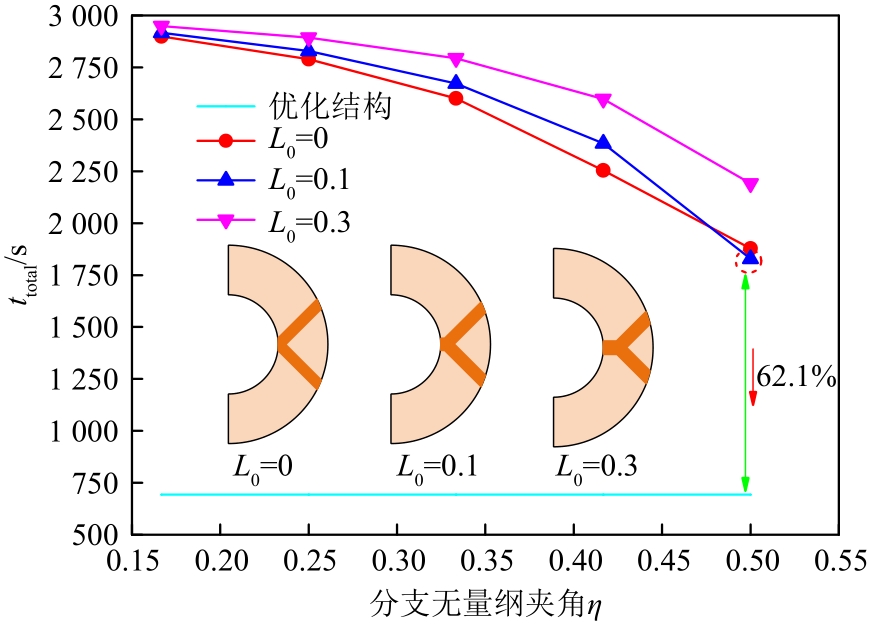

相变储热技术在太阳能热发电领域具有广阔的应用前景,翅片可以有效提升相变储热器的充放热速率。然而,相变储热的动态非线性特征严重制约了储热器内翅片结构的优化研究,因此提出了一种用于优化相变储热器内翅片结构的快速优化算法。该算法以相变材料到翅片和冷源的距离最短为优化目标,利用遗传算法对翅片的结构进行优化,解决了传统数值优化方法耗时长的问题。以管壳式相变储热器内一级Y形翅片为例,在满足翅片材料用量一定的前提下,选择Y形翅片的各分支长度、宽度比以及分支夹角作为设计变量,并对翅片的数量进行了影响分析。结果表明:提出的优化目标具有可行性,优化后的翅片结构呈现箭头形。在所研究的放热工况下,相比于传统Y形翅片,当翅片数量为1~3时,优化后的翅片结构可以使完全凝固时间缩短41.3%~62.1%。

中图分类号:

蔡肖, 徐阳, 杨超, 郑章靖. 一种相变储热器内翅片结构的快速优化算法[J]. 发电技术, 2022, 43(1): 92-101.

Xiao CAI, Yang XU, Chao YANG, Zhangjing ZHENG. A Fast Optimization Algorithm for Fin Structure of Phase Change Thermal Storage[J]. Power Generation Technology, 2022, 43(1): 92-101.

| 结构类型 | L0 | L1 | W0 | W1 | δ | |

|---|---|---|---|---|---|---|

| case0 | 0.979 | 0.656 | 0.040 | 0.039 | 0.960 | 0.745 |

| case1 | 0.952 | 0.614 | 0.043 | 0.040 | 0.937 | 0.715 |

表1 优化后翅片结构参数

Tab. 1 The optimized fin structure parameters

| 结构类型 | L0 | L1 | W0 | W1 | δ | |

|---|---|---|---|---|---|---|

| case0 | 0.979 | 0.656 | 0.040 | 0.039 | 0.960 | 0.745 |

| case1 | 0.952 | 0.614 | 0.043 | 0.040 | 0.937 | 0.715 |

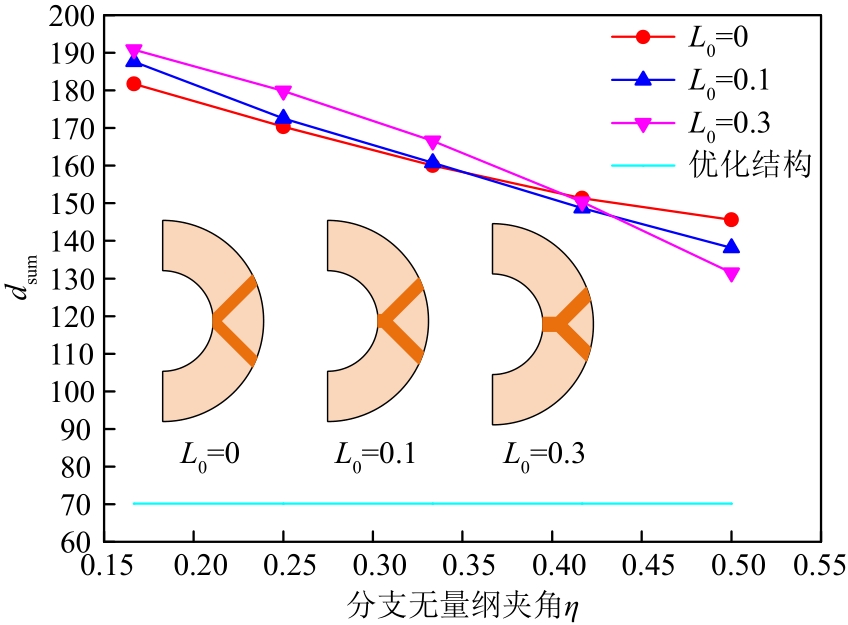

图11 不同结构的翅片管壳式相变储热器内相变材料到翅片和冷源的距离

Fig. 11 Distance between phase change material and fin and cold source in different finned shell and tube phase change heat storage

图12 不同结构参数的翅片管壳式相变储热器的完全凝固时间

Fig. 12 Complete solidification time of finned shell and tube phase change heat storage with different structural parameters

| 数量 | L0 | L1 | W0 | W1 | δ | |

|---|---|---|---|---|---|---|

| N=2 | 0.853 | 0.576 | 0.083 | 0.018 | 0.217 | 0.637 |

| N=3 | 0.944 | 0.539 | 0.059 | 0.013 | 0.220 | 0.669 |

表2 不同数量下优化后翅片结构参数

Tab. 2 Optimized parameters of fin structure under different numbers

| 数量 | L0 | L1 | W0 | W1 | δ | |

|---|---|---|---|---|---|---|

| N=2 | 0.853 | 0.576 | 0.083 | 0.018 | 0.217 | 0.637 |

| N=3 | 0.944 | 0.539 | 0.059 | 0.013 | 0.220 | 0.669 |

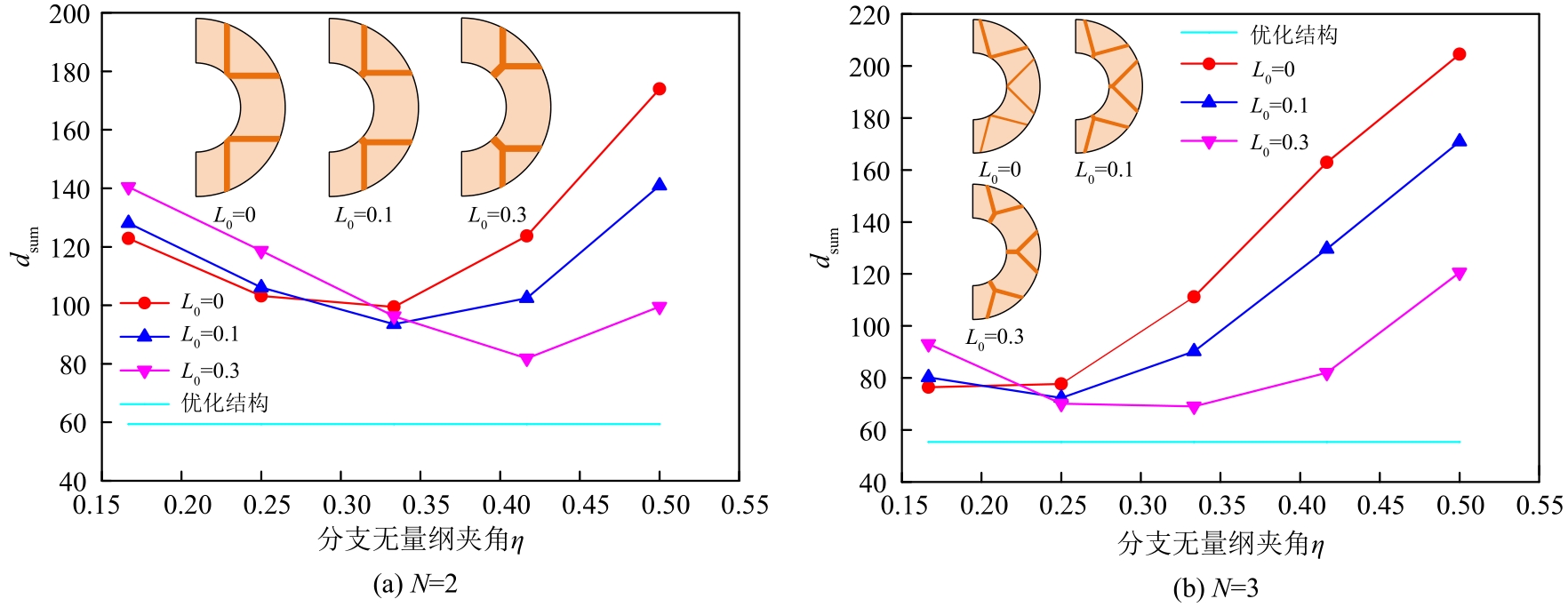

图15 不同数量、不同结构翅片储热器内相变材料到翅片和冷源的距离

Fig. 15 Distance between phase change material and fin and cold source in different number and structures of fin heat reservoir

| 1 | ZHENG Z J, LI M J, HE Y L .Thermal analysis of solar central receiver tube with porous inserts and non-uniform heat flux[J]. Applied Energy,2017,185:1152-1161. doi:10.1016/j.apenergy.2015.11.039 |

| 2 | 窦东,姚李孝 .含光热电站的联合发电系统优化调度[J].电网与清洁能源,2021,37(6):83-88. doi:10.3969/j.issn.1674-3814.2021.06.011 |

| DOU D, YAO L X .Multi-objective optimal scheduling of combined power generation system containing solar thermal power station[J].Power System and Clean Energy,2021,37(6):83-88. doi:10.3969/j.issn.1674-3814.2021.06.011 | |

| 3 | 谢昱卓,李刚,倪杭飞 .基于特征算法的塔式光热电站镜场云识别技术研究[J].智慧电力,2021,49(11):38-44. doi:10.3969/j.issn.1673-7598.2021.11.007 |

| XIE Y Z, LI G, NI H F .Cloud recognition in heliostat field of tower concentrating solar power station based on feature algorithm[J].Smart Power,2021,49(11):38-44. doi:10.3969/j.issn.1673-7598.2021.11.007 | |

| 4 | 张哲旸,巨星,潘信宇,等 .太阳能光伏-光热复合发电技术及其商业化应用[J].发电技术,2020,41(3):14-24. doi:10.12096/j.2096-4528.pgt.19137 |

| ZHANG Z C, JU X, PAN X Y,et al .Photovoltaic/concentrated solar power hybrid technology and its commercial application[J].Power Generation Technology,2020,41(3):14-24. doi:10.12096/j.2096-4528.pgt.19137 | |

| 5 | KHAN Z, GHAFOOR A .A review of performance enhancement of PCM based latent heat storage system within the context of materials, thermal stability and compatibility[J].Energy Conversion and Management,2016,115:132-158. doi:10.1016/j.enconman.2016.02.045 |

| 6 | 郑章靖,徐阳,何雅玲 .梯级多孔介质强化管壳式相变储热器性能研究[J].工程热物理学报,2019,40(3):129-35. |

| ZHENG Z J, XU Y, HE Y L .Study on the performance of a shell-and-tube latent-heat storage unit enhanced by porous medium with graded porosity[J].Journal of Engineering Thermophysics,2019,40(3):129-35. | |

| 7 | ABDULATEEF A M,MAT S, ABDULATEEF J,et al .Geometric and design parameters of fins employed for enhancing thermal energy storage systems: a review[J].Renewable and Sustainable Energy Reviews,2018,82:1620-1635. doi:10.1016/j.rser.2017.07.009 |

| 8 | DHAIDAN N S, KHODADADI J M . Improved performance of latent heat energy storage systems utilizing high thermal conductivity fins: a review[J]. Journal of Renewable and Sustainable Energy,2017,9(3):034103. doi:10.1063/1.4989738 |

| 9 | ZHAO M, TIAN Y, HU M,et al .Topology optimization of fins for energy storage tank with phase change material[J].Numerical Heat Transfer,Part A:Applications,2019, 77(3):284-301. doi:10.1080/10407782.2019.1690338 |

| 10 | YU C, WU S, HUANG Y,et al .Charging performance optimization of a latent heat storage unit with fractal tree-like fins[J].Journal of Energy Storage,2020, 30:101498. doi:10.1016/j.est.2020.101498 |

| 11 | ZHANG C, SUN Q, CHEN Y .Solidification behaviors and parametric optimization of finned shell-tube ice storage units[J].International Journal of Heat and Mass Transfer,2020,146:118836. doi:10.1016/j.ijheatmasstransfer.2019.118836 |

| 12 | XU Y, ZHENG Z J, CHEN S,et al .Parameter analysis and fast prediction of the optimum eccentricity for a latent heat thermal energy storage unit with phase change material enhanced by porous medium[J].Applied Thermal Engineering,2021,186:116485. doi:10.1016/j.applthermaleng.2020.116485 |

| 13 | XU Y, REN Q, ZHENG Z J,et al .Evaluation and optimization of melting performance for a latent heat thermal energy storage unit partially filled with porous media[J].Applied Energy,2017, 193:84-95. doi:10.1016/j.apenergy.2017.02.019 |

| 14 | ZHENG Z J, XU Y, LI M J .Eccentricity optimization of a horizontal shell-and-tube latent-heat thermal energy storage unit based on melting and melting-solidifying performance[J].Applied Energy,2018, 220:447-454. doi:10.1016/j.apenergy.2018.03.126 |

| 15 | ISMAIL K A R, ALVES C L F, MODESTO M S .Numerical and experimental study on the solidification of PCM around a vertical axially finned isothermal cylinder[J].Applied Thermal Engineering,2001,21(1):53-77. doi:10.1016/s1359-4311(00)00002-8 |

| 16 | ZHENG Z J, LI M J, HE Y L .Optimization of porous insert configurations for heat transfer enhancement in tubes based on genetic algorithm and CFD[J].International Journal of Heat and Mass Transfer,2015, 87:376-379. doi:10.1016/j.ijheatmasstransfer.2015.04.016 |

| 17 | ZHENG Z J, YANG X U, YALING H E .Thermal analysis of a solar parabolic trough receiver tube with porous insert optimized by coupling genetic algorithm and CFD[J].Science China (Technological Sciences),2016,59(10):1475-1485. doi:10.1007/s11431-016-0373-x |

| [1] | 孙健浩, 初壮. 考虑碳交易和无功补偿的分布式电源优化配置[J]. 发电技术, 2024, 45(1): 142-150. |

| [2] | 高中亮, 耿奇, 王哲, 高婷, 李英峰, 陈雷, 李美成. 基于硅纳米线的PEDOT:PSS/Si杂化太阳电池结构优化及实验研究[J]. 发电技术, 2023, 44(5): 685-695. |

| [3] | 赵国钦, 蓝茂蔚, 李杨, 周元祥, 江政纬, 甘云华. 基于最小二乘支持向量机的火电厂烟气含氧量预测模型优化研究[J]. 发电技术, 2023, 44(4): 534-542. |

| [4] | 郭学伯, 范良迟, 许浈婧, 李有, 林俊, 陈林. 助力节能降碳的相变储热材料研究和应用进展[J]. 发电技术, 2023, 44(2): 201-212. |

| [5] | Mohamed ABD-HAMID, 夏龙禹, 魏高升, 崔柳, 徐超, 杜小泽. 集成相变储热材料的光伏/热复合系统性能分析[J]. 发电技术, 2023, 44(1): 53-62. |

| [6] | 亢猛, 钟祎勍, 石鑫, 温港成, 房方. 计及负荷供给可靠性的园区综合能源系统两阶段优化方法研究[J]. 发电技术, 2023, 44(1): 25-35. |

| [7] | 雷旭, 马鹏飞, 宋智帅, 李卫东. 计及风电预测误差的柔性负荷日内调度模型[J]. 发电技术, 2022, 43(3): 485-491. |

| [8] | 肖瑶, 钮文泽, 魏高升, 崔柳, 杜小泽. 太阳能光伏/光热技术研究现状与发展趋势综述[J]. 发电技术, 2022, 43(3): 392-404. |

| [9] | 廖志荣, 李朋达, 田紫芊, 徐超, 魏高升. 非均匀翅片对级联相变储热系统热性能强化的研究[J]. 发电技术, 2022, 43(1): 83-91. |

| [10] | 蒋猛,黄宇,廖伟涵,张简炼,张又文,郭创新. 基于改进NSGA-Ⅱ算法的电-气-热综合能源系统多目标优化[J]. 发电技术, 2020, 41(2): 131-136. |

| [11] | 李卫东,贺鸿鹏. 考虑风电消纳的源-荷协同优化调度策略[J]. 发电技术, 2020, 41(2): 126-130. |

| [12] | 孙黎霞,鞠平,白景涛,刘甜甜. 计及蓄电池寿命的冷热电联供型微电网多目标经济优化运行[J]. 发电技术, 2020, 41(1): 64-72. |

| [13] | 刘永前,赖福兴,阎洁,陈子新,李莉,韩爽,王永. 考虑不同截面翼型选取的风电机组叶片优化设计方法[J]. 发电技术, 2019, 40(4): 382-388. |

| [14] | 唐诗洁,陆强,曲艳超,任翠涛,杨勇平. 基于遗传算法优化BP神经网络的SCR脱硝系统催化剂体积设计[J]. 发电技术, 2019, 40(3): 246-252. |

| [15] | 魏高升,王遥,杨彦平,徐超,杜小泽. 基于孔尺度的泡沫金属强化相变储热材料传热性能数值模拟[J]. 发电技术, 2018, 39(2): 158-164. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||