“双碳”目标下清洁高效灵活煤电技术现状及煤电前景展望

1

2023

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

Techniques status and perspective of efficient-flexible coal fired power generation under carbon peak and neutrality targets

1

2023

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

基于“双碳”目标的中国火力发电技术发展路径研究

0

2023

Research on the development path of China’s thermal power generation technology based on the goal of “carbon peak and carbon neutralization”

0

2023

广东电力低碳高质量发展下的电煤需求影响分析

0

2023

Influence analysis of thermal coal demand under the low-carbon and high-quality development of electric power in Guangdong Province

0

2023

“双碳” 目标下煤电机组节能改造技术发展与实践

0

2024

Development and practice of energy-saving retrofit technologies for coal power units under carbon peaking and carbon neutrality goals

0

2024

新疆能耗双控向碳排放双控转变分析和预测

1

2024

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

Analysis and forecast of the shift from double control of energy consumption to double control of carbon emissions in Xinjiang

1

2024

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

燃准东煤电站锅炉沾污结渣特性及防治措施研究进展

1

2024

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

Research progress on the characteristics and countermeasures of ash slagging and fouling in boilers burning Zhundong coal

1

2024

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

Distribution,occurrence and leaching dynamic behavior of sodium in Zhundong coal

1

2017

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

燃用准东煤过程中碱/碱土金属迁移规律及锅炉结渣沾污研究进展

1

2020

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

Transformation of AAEM and ash deposition characteristics during combustion of Zhundong coal

1

2020

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

The morphological and mineralogical characteristics and thermal conductivity of ash deposits in a 220 MW CFBB firing Zhundong lignite

1

2023

... 煤炭是我国的主体能源[1-5],新疆地区的准东煤因其3 900亿t的预测储量成为我国重要的能源供应基地[6].准东煤具有低灰分、低硫分、低着火温度和高燃尽率的良好煤质特性,但是煤灰中的碱金属含量也普遍较高(质量分数>2%)[7].目前,煤粉锅炉[8]和循环流化床锅炉[9]燃用准东煤时,都会出现不同程度的沾污结渣现象,成为锅炉长周期安全稳定运行的主要技术瓶颈. ...

Size distribution of fine particles from coal combustion

1

1982

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

添加石灰石对准东煤CFB燃烧过程床料团聚和受热面积灰的影响

1

2024

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

Effect of limestone addition on bed particle agglomeration and ash deposition on heat transfer surface during Zhundong coal combustion in a circulating fluidized bed

1

2024

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

高碱煤钠赋存形态及其燃烧过程中迁移转化的研究进展

1

2019

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

Occurrence of sodium in high alkali coal and its transformation during combustion

1

2019

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

Measurement of atomic sodium release during pyrolysis and combustion of sodium-enriched Zhundong coal pellet

1

2017

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

Ash formation and deposition in coal and biomass fired combustion systems:progress and challenges in the field of ash particle sticking and rebound behavior

1

2018

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

Shedding of ash deposits

1

2009

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

Fine particulate formation and ash deposition during pulverized coal combustion of high-sodium lignite in a down-fired furnace

1

2015

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

Experimental measurement of the effective thermal conductivity of ash deposit for high sodium coal (Zhun Dong coal) in a 300 KW test furnace

1

2013

... 国内外学者对准东煤的成灰特性和灰沉积特性进行了大量分析[10-11].研究发现,准东煤中的钠主要以氯化钠晶体或水合离子形式存在[12].在燃烧过程中,相当比例的碱金属钠会以气相的形式释放到烟气中,随后通过冷凝、扩散等方式沉积到受热面上[13].其他无机灰分,如钙镁硫化物、硅酸盐或硅铝酸盐,也可以通过热泳或惯性撞击等机理沉积在受热面上[14].随着时间的积累,沉积灰经历生长、脱落、烧结、流动等过程,最终形成松散的、烧结的,甚至熔融的积灰[15].当沉积灰通过烧结和熔融增强颗粒间的黏性作用力时,吹灰手段就可能失效,使得锅炉经济性降低、安全风险显著升高[16-17]. ...

准东煤飞灰沉积特性及数值模拟研究

1

2024

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

Sedimentation characteristics and numerical simulation of Zhundong coal fly ash

1

2024

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

A temperature-history based model for the sticking probability of impacting pulverized coal ash particles

2

2016

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

... 通过计算沉积灰颗粒的平均黏附能,还可以对不同积灰阶段沉积灰脱除所需要的条件进行计算.表4给出了不同积灰时间段沉积灰颗粒的平均黏附能和所需的吹灰质量流率.可知,随着灰沉积时间的延长,换热管道沉积灰黏附能逐渐增大,6 h灰沉积时间段的换热管道沉积灰黏附能为1 h灰沉积时间段的6.11倍;吹灰装置所需空气出口质量流率也相应变大,6 h灰沉积时间段的吹灰装置出口质量流率为1 h灰沉积时间段的1.85倍.因此,在不同的积灰时间段吹灰时,还应当相应地调整吹灰的压力和空气(蒸汽)流量,以最大程度避免吹灰过度或吹灰不足现象.值得说明的是,现有研究暂时没有考虑沉积灰烧结使黏附能增大的情况,后续工作可结合灰的烧结以及烧结前后颗粒间的黏性变化[19, 31],进一步改进现有的侵蚀模型,确保模型的准确性和工程实用性. ...

Towards a CFD-based mechanistic deposit formation model for straw-fired boilers

1

2006

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

Real-time fouling characteristics of a typical heat exchanger used in the waste heat recovery systems

2

2017

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

... [21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

Prediction of potassium chloride sulfation and its effect on deposition in biomass-fired boilers

1

2012

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

A numerical simulation study of ash deposition in a circulating fluidized bed during Zhundong lignite combustion

10

2023

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

... [23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

... 本文的物理模型来自某循环流化床(circulating fluidized bed,CFB)水平烟道内空冷探针上的积灰过程,详细的实验系统及空冷探针布置情况见文献[27].模拟时,设定的计算域高度为100 mm,长度为500 mm,换热管道放置于计算域入口200 mm处,进口设置为速度边界条件,出口设置为压力边界条件[23].准东煤的煤质和煤灰特性见表1.具体的模拟输入条件见表2,其中温度和速度等均为实验测量值,飞灰颗粒粒径则先通过激光粒度仪分析,随后再根据R-R分布对其进行拟合得到[23].对于无法通过实验确定的沉积灰层孔隙率、飞灰颗粒导热率等参数,参照文献[28-30]确定. ...

... [23].对于无法通过实验确定的沉积灰层孔隙率、飞灰颗粒导热率等参数,参照文献[28-30]确定. ...

... 为揭示准东煤灰在换热壁面上的动态沉积和脱落过程,需要建立颗粒输运模型、颗粒沉积模型、侵蚀模型、传热模型和动网格模型.由于颗粒输运模型、颗粒沉积模型、传热模型和动网格模型已在作者先前的工作[23-24]中给出,在此主要给出侵蚀模型的构建过程. ...

... 在数值计算前,本文还进行了网格无关性分析,共生成了网格总数为52 381、109 884和136 921的网格系统,并在109 884与136 921网格数下得到了相似的结果.为节约运算时间,选择网格数为109 884的网格系统进行计算[23]. ...

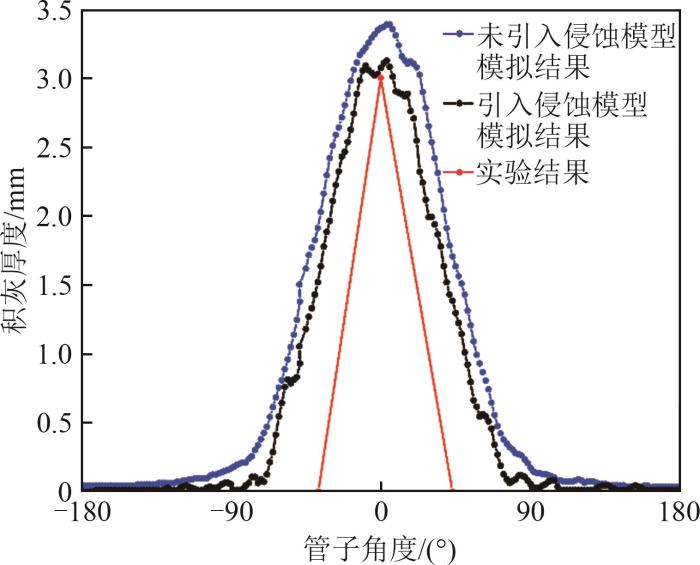

... 图1给出了积灰厚度及其分布特性模拟结果与实验结果的对比情况.可知,无论是实验研究还是数值模拟研究,积灰厚度均呈现出迎风面驻点处最高、向两侧位置发展依次降低的趋势,证实了数值模拟研究灰沉积的可行性.具体而言,未引入侵蚀模型时,模拟的灰锥高度约为3.3 mm[23],比相同6 h实验研究结果的3.0 mm高出0.3 mm;引入侵蚀模型后,灰锥的沉积灰层高度降至3.1 mm,与实验结果相比仅差0.1 mm.这表明侵蚀模型的引入使模型的精度更高,也证实了侵蚀模型的可靠性以及整体沉积数值模拟的准确性. ...

... 此外还发现,耦合侵蚀模型后的积灰厚度模拟结果在驻点处与未耦合的结果相差最大,说明由侵蚀导致的灰颗粒脱落行为在迎风侧的驻点处最为显著.这主要是因为:在驻点处的灰颗粒会产生更多的碰撞、反弹,由此对该区域产生更大的法向冲击能量[36];该区域沉积灰颗粒粒径较小,黏附能也相对较低.两者综合作用,导致此处侵蚀现象较为严重.而在换热管道两侧,这种侵蚀效应随着反弹灰颗粒数量的减少与平均沉积灰颗粒粒径的增大而减弱[23].值得说明的是,本文仅计算了灰颗粒的法向冲击能量,在非驻点处可能还存在灰颗粒的切向速度对沉积灰层的滑移脱落作用[32-33],在模拟时对此暂未考虑. ...

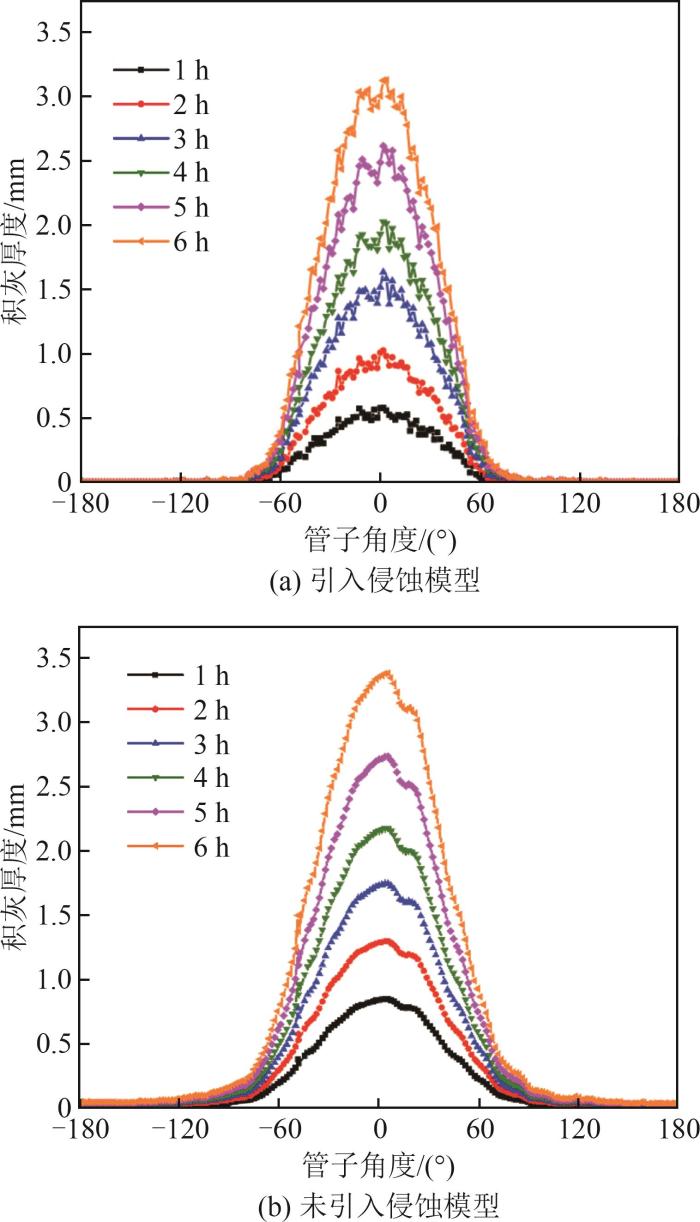

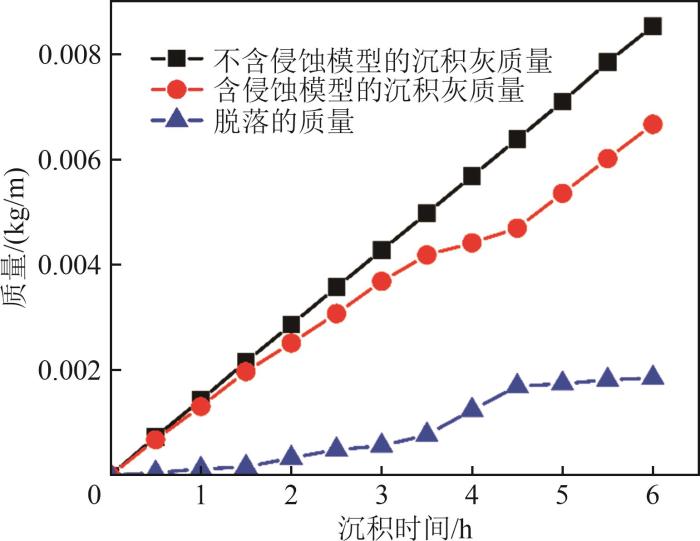

... 图3给出了换热管道沉积灰质量以及脱落的质量随时间的变化规律.由图3可以看出,不耦合侵蚀模型时,沉积灰的质量随时间呈线性变化规律,变化速率在6 h内相对较小,形成相对稳定的积灰生长过程.这主要是因为灰颗粒质量流率为恒定值,而其他因素(如沉积灰层形貌和沉积灰表面温度)的变化对沉积速率的影响相对较小[23]. ...

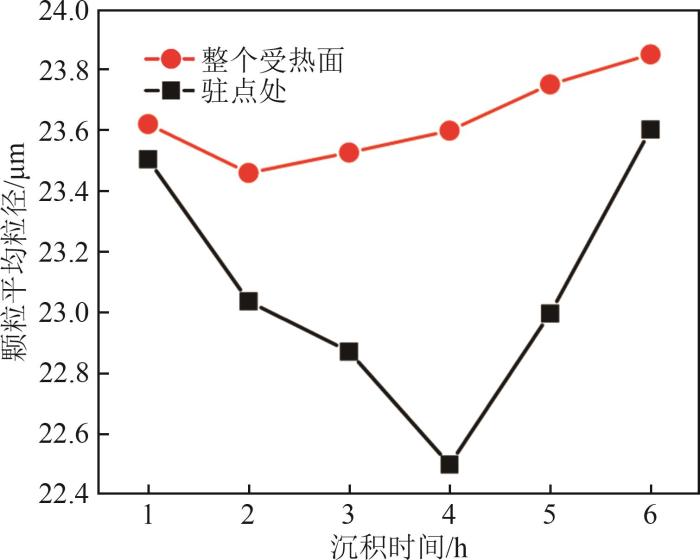

... 实际上,因驻点处碰撞颗粒数最多,侵蚀脱落现象最严重,采用该区域的平均粒径最能代表沉积灰的脱落过程.如图4所示,驻点网格面处沉积灰颗粒平均粒径在灰沉积4 h内呈现减小趋势,4 h后逐渐增大,这与图3所示的沉积灰脱落质量变化相对应,证实了颗粒粒径对侵蚀脱落的影响.这主要是因为,初期沉积灰量较少,沉积灰层整体偏平缓,更多的灰颗粒能够以法向方向直接撞击,导致沉积灰颗粒粒径偏小;而经过一段时间后,沉积灰层呈明显圆锥状,此时圆心角较小,更多灰颗粒斜向撞击换热壁面,导致沉积灰颗粒粒径逐渐变大[23]. ...

A numerical simulation study into the effect of longitudinal and transverse pitch on deposition of Zhundong coal ash on tube bundles

3

2024

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

... [24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

... 为揭示准东煤灰在换热壁面上的动态沉积和脱落过程,需要建立颗粒输运模型、颗粒沉积模型、侵蚀模型、传热模型和动网格模型.由于颗粒输运模型、颗粒沉积模型、传热模型和动网格模型已在作者先前的工作[23-24]中给出,在此主要给出侵蚀模型的构建过程. ...

Design of a novel,intensified heat exchanger for reduced fouling rates

2

2005

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

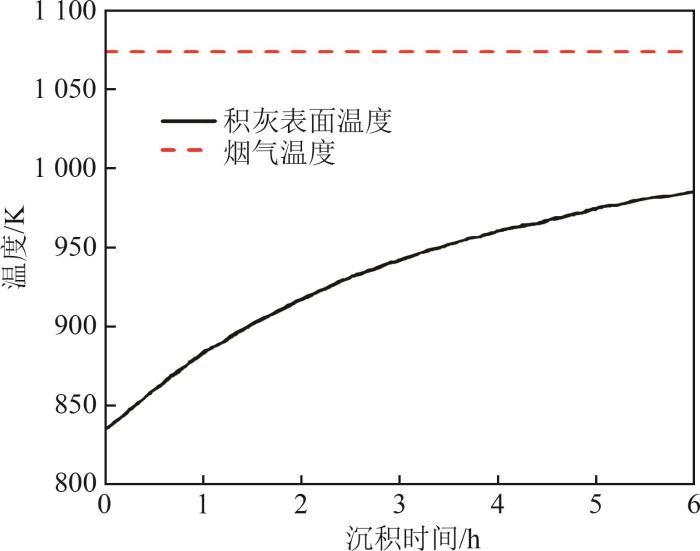

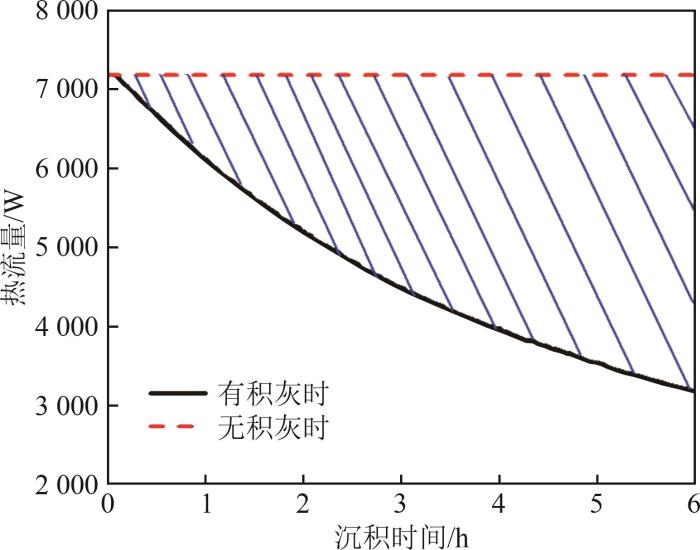

... 准东煤灰在受热面上的沉积会影响管外烟气与管内工质的传热,使换热效率降低,进而造成能量损失.因此,本文计算了积灰动态沉积过程的传热损耗变化,计算结果如图6所示.可知,在受热面无积灰的情况下,管道表面与烟气间的温差为238 K.在这种情况下,管外烟气与管内工质的热流量为恒定值7 200 W.随着灰的沉积,管外烟气与管内工质换热的热流量呈抛物线下降趋势,与文献[25]研究结果一致.积灰1 h后,积灰程度相对较轻,但此时管外烟气与管内工质的热流量已经降为6 000 W左右,出现了10%的传热损耗.积灰6 h后,受热面形成高度为3.1 mm的灰锥,此时的热流量降低至3 500 W,积灰的存在导致50%的传热损耗,管外烟气与管内工质的换热效率大大降低. ...

Numerical simulation of ash deposition behavior with a novel erosion model using dynamic mesh

3

2021

... 与实验手段相比,通过数值模拟可以对沉积灰的沉积、脱落等动态过程以及沉积机理的作用效果进行分析,因此成为研究灰沉积的主要手段[18].截至目前,国内外学者在考虑不同沉积机理的情况下,开发出了临界黏度模型[19]、熔体分数模型[20]、临界速度模型[21]和冷凝沉积模型[22]等,各模型的优缺点详见文献[23-24].近期,Liang等[23]和Guo等[24]采用修正后的黏度模型很好地预测了准东煤灰的沉积过程.与此同时,已沉积的灰颗粒会在飞灰和吹灰介质的冲击侵蚀下发生脱落.对此,Bouris等[25]开发建立了一个耦合脱落机理的数值模型,并对某燃褐煤电站锅炉的灰沉积过程进行了数值模拟研究.此外,Wang等[21]通过能量守恒研究了沉积灰的流动特性与实时污垢特性.Zhou等[26]引入了一种新的侵蚀模型,并对颗粒撞击过程消耗的能量和沉积表面的熔体分数进行了系统分析,结果显示,耦合侵蚀模型后沉积灰层的厚度与实验结果更为接近.然而,目前对准东煤灰沉积和脱落过程的认识仍然不足,如何根据其脱落特性对吹灰过程进行优化更鲜有报道. ...

... 灰颗粒撞击后的能量耗散主要由颗粒塑性变形以及弹性波在沉积灰层中的传播和耗散引起.因此以校正系数[26]表征侵蚀能量占灰颗粒撞击总耗散能量的比值,碰撞灰颗粒的侵蚀能量∆E计算式如下: ...

... 为加速模型计算,本文采用了异步生长法.当流场稳定后,假设沉积生长速率在一段时间内恒定(本文设置为1 s),即在数值上以一个时间步长的100倍代表实际过程中1 s的沉积速率,网格变化时,同样以单位时间步长的100倍进行网格变化.通过这种方法能够大幅度减少计算时间,且该方法已被大量使用[26-28].本文选择模拟计算时间为6 h,与先前实验研究[27]一致. ...

An experimental investigation into mineral transformation,particle agglomeration and ash deposition during combustion of Zhundong lignite in a laboratory-scale circulating fluidized bed

3

2019

... 本文的物理模型来自某循环流化床(circulating fluidized bed,CFB)水平烟道内空冷探针上的积灰过程,详细的实验系统及空冷探针布置情况见文献[27].模拟时,设定的计算域高度为100 mm,长度为500 mm,换热管道放置于计算域入口200 mm处,进口设置为速度边界条件,出口设置为压力边界条件[23].准东煤的煤质和煤灰特性见表1.具体的模拟输入条件见表2,其中温度和速度等均为实验测量值,飞灰颗粒粒径则先通过激光粒度仪分析,随后再根据R-R分布对其进行拟合得到[23].对于无法通过实验确定的沉积灰层孔隙率、飞灰颗粒导热率等参数,参照文献[28-30]确定. ...

... 为加速模型计算,本文采用了异步生长法.当流场稳定后,假设沉积生长速率在一段时间内恒定(本文设置为1 s),即在数值上以一个时间步长的100倍代表实际过程中1 s的沉积速率,网格变化时,同样以单位时间步长的100倍进行网格变化.通过这种方法能够大幅度减少计算时间,且该方法已被大量使用[26-28].本文选择模拟计算时间为6 h,与先前实验研究[27]一致. ...

... 耦合侵蚀模型后,沉积灰的质量在前1.5 h内与无侵蚀模型时基本一致,但随着时间的推移,沉积灰的质量逐渐降低,在6 h处已经与无侵蚀模型有了明显的差异,表明由飞灰颗粒侵蚀导致的脱落现象越来越显著.而就侵蚀脱落速率而言,沉积灰侵蚀脱落速率在初始1.5 h内基本维持在0.000 12 kg/(m⋅h);随后在1.5~3.5 h阶段逐渐变大并在3.5~4.5 h阶段达到峰值,且在最后的4.5~6 h保持此水平.此外还可以发现,脱落的沉积灰质量约占总沉积量的25%,说明由飞灰颗粒本身冲击造成的积灰脱落量相对较少,还需要其他手段[27]来清除受热面上的积灰. ...

Dynamic simulation on ash deposition and heat transfer behavior on a staggered tube bundle under high-temperature conditions

3

2020

... 本文的物理模型来自某循环流化床(circulating fluidized bed,CFB)水平烟道内空冷探针上的积灰过程,详细的实验系统及空冷探针布置情况见文献[27].模拟时,设定的计算域高度为100 mm,长度为500 mm,换热管道放置于计算域入口200 mm处,进口设置为速度边界条件,出口设置为压力边界条件[23].准东煤的煤质和煤灰特性见表1.具体的模拟输入条件见表2,其中温度和速度等均为实验测量值,飞灰颗粒粒径则先通过激光粒度仪分析,随后再根据R-R分布对其进行拟合得到[23].对于无法通过实验确定的沉积灰层孔隙率、飞灰颗粒导热率等参数,参照文献[28-30]确定. ...

... Simulation input conditions

Tab. 2| 参数 | 数值 | 来源 |

|---|

| 烟气温度/K | 1 073 | 实验 |

| 探针温度/K | 823 | 实验 |

| 入口速度/(m/s) | 15 | 实验 |

| 飞灰质量流量/(kg/s) | 0.000 24 | 实验 |

| 飞灰密度/(kg/m3) | 2 500 | 文献[28] |

| 沉积灰层孔隙率 | 0.5 | 文献[29] |

| 飞灰导热率/[W/(m⋅K)] | 1.89 | 文献[30] |

2 数学模型及求解为揭示准东煤灰在换热壁面上的动态沉积和脱落过程,需要建立颗粒输运模型、颗粒沉积模型、侵蚀模型、传热模型和动网格模型.由于颗粒输运模型、颗粒沉积模型、传热模型和动网格模型已在作者先前的工作[23-24]中给出,在此主要给出侵蚀模型的构建过程. ...

... 为加速模型计算,本文采用了异步生长法.当流场稳定后,假设沉积生长速率在一段时间内恒定(本文设置为1 s),即在数值上以一个时间步长的100倍代表实际过程中1 s的沉积速率,网格变化时,同样以单位时间步长的100倍进行网格变化.通过这种方法能够大幅度减少计算时间,且该方法已被大量使用[26-28].本文选择模拟计算时间为6 h,与先前实验研究[27]一致. ...

Mechanistic modeling,numerical simulation and validation of slag-layer growth in a coal-fired boiler

1

2015

... Simulation input conditions

Tab. 2| 参数 | 数值 | 来源 |

|---|

| 烟气温度/K | 1 073 | 实验 |

| 探针温度/K | 823 | 实验 |

| 入口速度/(m/s) | 15 | 实验 |

| 飞灰质量流量/(kg/s) | 0.000 24 | 实验 |

| 飞灰密度/(kg/m3) | 2 500 | 文献[28] |

| 沉积灰层孔隙率 | 0.5 | 文献[29] |

| 飞灰导热率/[W/(m⋅K)] | 1.89 | 文献[30] |

2 数学模型及求解为揭示准东煤灰在换热壁面上的动态沉积和脱落过程,需要建立颗粒输运模型、颗粒沉积模型、侵蚀模型、传热模型和动网格模型.由于颗粒输运模型、颗粒沉积模型、传热模型和动网格模型已在作者先前的工作[23-24]中给出,在此主要给出侵蚀模型的构建过程. ...

Dynamic CFD modeling evaluation of ash deposition behavior and morphology evolution with different tube arrangements

2

2021

... 本文的物理模型来自某循环流化床(circulating fluidized bed,CFB)水平烟道内空冷探针上的积灰过程,详细的实验系统及空冷探针布置情况见文献[27].模拟时,设定的计算域高度为100 mm,长度为500 mm,换热管道放置于计算域入口200 mm处,进口设置为速度边界条件,出口设置为压力边界条件[23].准东煤的煤质和煤灰特性见表1.具体的模拟输入条件见表2,其中温度和速度等均为实验测量值,飞灰颗粒粒径则先通过激光粒度仪分析,随后再根据R-R分布对其进行拟合得到[23].对于无法通过实验确定的沉积灰层孔隙率、飞灰颗粒导热率等参数,参照文献[28-30]确定. ...

... Simulation input conditions

Tab. 2| 参数 | 数值 | 来源 |

|---|

| 烟气温度/K | 1 073 | 实验 |

| 探针温度/K | 823 | 实验 |

| 入口速度/(m/s) | 15 | 实验 |

| 飞灰质量流量/(kg/s) | 0.000 24 | 实验 |

| 飞灰密度/(kg/m3) | 2 500 | 文献[28] |

| 沉积灰层孔隙率 | 0.5 | 文献[29] |

| 飞灰导热率/[W/(m⋅K)] | 1.89 | 文献[30] |

2 数学模型及求解为揭示准东煤灰在换热壁面上的动态沉积和脱落过程,需要建立颗粒输运模型、颗粒沉积模型、侵蚀模型、传热模型和动网格模型.由于颗粒输运模型、颗粒沉积模型、传热模型和动网格模型已在作者先前的工作[23-24]中给出,在此主要给出侵蚀模型的构建过程. ...

Deposition of bituminous coal ash on an isolated heat exchanger tube:effects of coal properties on deposit growth

2

1990

... 本文基于能量守恒,通过对比反弹灰颗粒对换热壁面的冲击能量与沉积灰层内部黏附能量的大小,来确定沉积灰的脱落量.反弹灰颗粒的冲击能量在Walsh等[31]的初始研究中以定值表示,在本文中应用文献[32-33]提出的灰颗粒冲击能量计算公式对不同速度、不同粒径的灰颗粒冲击能量进行计算.当灰颗粒撞击换热壁面时,碰撞前灰颗粒所具有的能量E与冲击后的剩余能量计算式如下: ...

... 通过计算沉积灰颗粒的平均黏附能,还可以对不同积灰阶段沉积灰脱除所需要的条件进行计算.表4给出了不同积灰时间段沉积灰颗粒的平均黏附能和所需的吹灰质量流率.可知,随着灰沉积时间的延长,换热管道沉积灰黏附能逐渐增大,6 h灰沉积时间段的换热管道沉积灰黏附能为1 h灰沉积时间段的6.11倍;吹灰装置所需空气出口质量流率也相应变大,6 h灰沉积时间段的吹灰装置出口质量流率为1 h灰沉积时间段的1.85倍.因此,在不同的积灰时间段吹灰时,还应当相应地调整吹灰的压力和空气(蒸汽)流量,以最大程度避免吹灰过度或吹灰不足现象.值得说明的是,现有研究暂时没有考虑沉积灰烧结使黏附能增大的情况,后续工作可结合灰的烧结以及烧结前后颗粒间的黏性变化[19, 31],进一步改进现有的侵蚀模型,确保模型的准确性和工程实用性. ...

The effects of wetting and surface roughness on liquid metal droplet bouncing

2

2009

... 本文基于能量守恒,通过对比反弹灰颗粒对换热壁面的冲击能量与沉积灰层内部黏附能量的大小,来确定沉积灰的脱落量.反弹灰颗粒的冲击能量在Walsh等[31]的初始研究中以定值表示,在本文中应用文献[32-33]提出的灰颗粒冲击能量计算公式对不同速度、不同粒径的灰颗粒冲击能量进行计算.当灰颗粒撞击换热壁面时,碰撞前灰颗粒所具有的能量E与冲击后的剩余能量计算式如下: ...

... 此外还发现,耦合侵蚀模型后的积灰厚度模拟结果在驻点处与未耦合的结果相差最大,说明由侵蚀导致的灰颗粒脱落行为在迎风侧的驻点处最为显著.这主要是因为:在驻点处的灰颗粒会产生更多的碰撞、反弹,由此对该区域产生更大的法向冲击能量[36];该区域沉积灰颗粒粒径较小,黏附能也相对较低.两者综合作用,导致此处侵蚀现象较为严重.而在换热管道两侧,这种侵蚀效应随着反弹灰颗粒数量的减少与平均沉积灰颗粒粒径的增大而减弱[23].值得说明的是,本文仅计算了灰颗粒的法向冲击能量,在非驻点处可能还存在灰颗粒的切向速度对沉积灰层的滑移脱落作用[32-33],在模拟时对此暂未考虑. ...

Surface energy and the contact of elastic solids

2

2007

... 本文基于能量守恒,通过对比反弹灰颗粒对换热壁面的冲击能量与沉积灰层内部黏附能量的大小,来确定沉积灰的脱落量.反弹灰颗粒的冲击能量在Walsh等[31]的初始研究中以定值表示,在本文中应用文献[32-33]提出的灰颗粒冲击能量计算公式对不同速度、不同粒径的灰颗粒冲击能量进行计算.当灰颗粒撞击换热壁面时,碰撞前灰颗粒所具有的能量E与冲击后的剩余能量计算式如下: ...

... 此外还发现,耦合侵蚀模型后的积灰厚度模拟结果在驻点处与未耦合的结果相差最大,说明由侵蚀导致的灰颗粒脱落行为在迎风侧的驻点处最为显著.这主要是因为:在驻点处的灰颗粒会产生更多的碰撞、反弹,由此对该区域产生更大的法向冲击能量[36];该区域沉积灰颗粒粒径较小,黏附能也相对较低.两者综合作用,导致此处侵蚀现象较为严重.而在换热管道两侧,这种侵蚀效应随着反弹灰颗粒数量的减少与平均沉积灰颗粒粒径的增大而减弱[23].值得说明的是,本文仅计算了灰颗粒的法向冲击能量,在非驻点处可能还存在灰颗粒的切向速度对沉积灰层的滑移脱落作用[32-33],在模拟时对此暂未考虑. ...

Particle deposition model for particulate flows at high temperatures in gas turbine components

1

2015

... 式中:为碰撞灰颗粒直径;为灰颗粒密度;为碰撞灰颗粒速度;为与表面粗糙度相关的有效接触面积分数,本文取0.9;为静态接触角,此处取一般颗粒物的67°;为灰颗粒表面张力系数,可由式(3)[34]计算得出;为潜在扩散比,可由式(4)[35]计算得出;D为撞击颗粒的最大扩散比,即撞击时灰颗粒的最大扩散直径与灰颗粒直径的比值,可基于Ni等[36]提出的扩散系数计算得出,其表达式见式(5)—(7). ...

Spread and rebound of liquid droplets upon impact on flat surfaces

1

1997

... 式中:为碰撞灰颗粒直径;为灰颗粒密度;为碰撞灰颗粒速度;为与表面粗糙度相关的有效接触面积分数,本文取0.9;为静态接触角,此处取一般颗粒物的67°;为灰颗粒表面张力系数,可由式(3)[34]计算得出;为潜在扩散比,可由式(4)[35]计算得出;D为撞击颗粒的最大扩散比,即撞击时灰颗粒的最大扩散直径与灰颗粒直径的比值,可基于Ni等[36]提出的扩散系数计算得出,其表达式见式(5)—(7). ...

Submodel for predicting slag deposition formation in slagging gasification systems

2

2011

... 式中:为碰撞灰颗粒直径;为灰颗粒密度;为碰撞灰颗粒速度;为与表面粗糙度相关的有效接触面积分数,本文取0.9;为静态接触角,此处取一般颗粒物的67°;为灰颗粒表面张力系数,可由式(3)[34]计算得出;为潜在扩散比,可由式(4)[35]计算得出;D为撞击颗粒的最大扩散比,即撞击时灰颗粒的最大扩散直径与灰颗粒直径的比值,可基于Ni等[36]提出的扩散系数计算得出,其表达式见式(5)—(7). ...

... 此外还发现,耦合侵蚀模型后的积灰厚度模拟结果在驻点处与未耦合的结果相差最大,说明由侵蚀导致的灰颗粒脱落行为在迎风侧的驻点处最为显著.这主要是因为:在驻点处的灰颗粒会产生更多的碰撞、反弹,由此对该区域产生更大的法向冲击能量[36];该区域沉积灰颗粒粒径较小,黏附能也相对较低.两者综合作用,导致此处侵蚀现象较为严重.而在换热管道两侧,这种侵蚀效应随着反弹灰颗粒数量的减少与平均沉积灰颗粒粒径的增大而减弱[23].值得说明的是,本文仅计算了灰颗粒的法向冲击能量,在非驻点处可能还存在灰颗粒的切向速度对沉积灰层的滑移脱落作用[32-33],在模拟时对此暂未考虑. ...

Numerical investigation on development of initial ash deposition layer for a high-alkali coal

2

2017

... 对于沉积灰层内部的灰颗粒黏附能量,基于Liu等[37]的研究,应用碱涂层表面黏附模型进行计算.上述研究认为,沉积灰层中的灰颗粒黏附能是由沉积灰颗粒表面黏性层与沉积灰层表面黏性层的表面张力作用主导的.基于此,黏性涂层的厚度计算如下: ...

... 在入口灰颗粒恒定的情况下,沉积灰侵蚀脱落质量由灰颗粒的平均黏附能控制,而这又由不同网格面的沉积灰颗粒平均粒径与沉积灰层表面温度(表面张力系数)决定[37].图4给出了沉积灰平均粒径随时间的变化.其中,驻点处的平均粒径曲线为换热管道迎风侧驻点处对应网格面内的沉积灰颗粒平均粒径,也就是驻点处网格面内的平均黏附能计算粒径;而整个换热管道表面的平均粒径由整个换热管道上的沉积灰颗粒粒径进行平均得到.由图4可得,换热表面总沉积灰颗粒的平均粒径随时间的变化趋势较平缓,虽然在灰沉积初期(2 h内)有小部分下降趋势,但在2 h后平均粒径呈缓慢上升趋势.由此可以发现,侵蚀脱落的沉积灰质量与沉积灰颗粒平均粒径并不是完全一一对应. ...

煤电机组运行灵活性提升技术研究与应用

1

2024

... 在实际工业中,采用吹灰手段对积灰进行脱除[38-40].然而,由于无法准确针对沉积灰量执行相应强度的吹灰动作,往往会出现吹灰过度和吹灰不足的情况,前者会导致管道磨损,而后者会使得积灰无法清除.针对这种情况,本文对不同阶段沉积灰的黏附能量进行了计算,随后通过确定相应的吹灰条件,使换热管恢复至清洁状态. ...

Research and application of operation flexibility improvement technology for coal-fired power unit

1

2024

... 在实际工业中,采用吹灰手段对积灰进行脱除[38-40].然而,由于无法准确针对沉积灰量执行相应强度的吹灰动作,往往会出现吹灰过度和吹灰不足的情况,前者会导致管道磨损,而后者会使得积灰无法清除.针对这种情况,本文对不同阶段沉积灰的黏附能量进行了计算,随后通过确定相应的吹灰条件,使换热管恢复至清洁状态. ...

一种T型吹灰装置在锅炉空气预热器上的应用

0

2023

Application of a T-type soot blowing device on bolier air preheater

0

2023

适应新型电力系统的调峰火电机组空气预热器安全评估策略

1

2024

... 在实际工业中,采用吹灰手段对积灰进行脱除[38-40].然而,由于无法准确针对沉积灰量执行相应强度的吹灰动作,往往会出现吹灰过度和吹灰不足的情况,前者会导致管道磨损,而后者会使得积灰无法清除.针对这种情况,本文对不同阶段沉积灰的黏附能量进行了计算,随后通过确定相应的吹灰条件,使换热管恢复至清洁状态. ...

Flexibility-oriented safety assessment strategy for air preheater in thermal power units adapting to the advanced power system

1

2024

... 在实际工业中,采用吹灰手段对积灰进行脱除[38-40].然而,由于无法准确针对沉积灰量执行相应强度的吹灰动作,往往会出现吹灰过度和吹灰不足的情况,前者会导致管道磨损,而后者会使得积灰无法清除.针对这种情况,本文对不同阶段沉积灰的黏附能量进行了计算,随后通过确定相应的吹灰条件,使换热管恢复至清洁状态. ...

Numerical simulation and experiment of gas-solid two phase flow and ash deposition on a novel heat transfer surface

1

2017

... 使用FLUENT对所构建的模型进行求解.求解设置时,采用SIMPLE求解器进行速度-压力耦合求解;压力、动量、湍流耗散率等均采用二阶迎风离散;湍流计算应用k-ω模型与壁面函数法进行求解;辐射换热采用P1模型并考虑颗粒与气体间的辐射换热;沉积表面处的流固耦合传热采用耦合换热模式进行求解;气固两相流通过离散相模型进行计算,考虑到相间的相互作用,为使流场计算更加精确,启用随机游走模型与随机涡寿命模型[41-42]. ...

A practical numerical approach for prediction of particulate fouling in PC boilers

1

2012

... 使用FLUENT对所构建的模型进行求解.求解设置时,采用SIMPLE求解器进行速度-压力耦合求解;压力、动量、湍流耗散率等均采用二阶迎风离散;湍流计算应用k-ω模型与壁面函数法进行求解;辐射换热采用P1模型并考虑颗粒与气体间的辐射换热;沉积表面处的流固耦合传热采用耦合换热模式进行求解;气固两相流通过离散相模型进行计算,考虑到相间的相互作用,为使流场计算更加精确,启用随机游走模型与随机涡寿命模型[41-42]. ...