0 引言

燃煤电厂烟气脱硫是控制SO2排放的关键,广泛应用的湿法脱硫技术能够有效去除SO2,但同时也带来了新的挑战。湿法脱硫过程中烟气会夹带大量细小脱硫剂液滴,如果不进行有效处理,会严重影响后续设备的运行和效率,甚至造成环境污染。

为了满足日益严格的环保要求,并保障机组的安全稳定运行,脱硫塔后通常安装除雾器进行气水分离[1]。然而,烟气携带浆液液滴经过除雾器时,容易在其板面上结垢堵塞,导致流动阻力增加,最高可达300~400 Pa,严重时会导致机组停机。针对此问题,很多学者提出了解决方法,如:张双平等[2]利用数值模拟的手段分析了除雾器安装高度对烟气携带浆液量的影响,研究发现,除雾器与喷淋层之间的高度以及喷淋浆液的雾化粒径对除雾器的除雾性能影响极大;禾志强等[3]研究指出,通过增加除雾器冲洗水压力,使其能更有效地冲刷掉垢体;潘超群[4]将浆液的pH值控制在合理范围内,成功减缓了除雾器板面上的结垢现象;马晓丽等[5]通过调整石膏浆液的pH值和更换新的除雾器清洗设备,解决了除雾器的堵塞问题;纪小春[6]研究指出,通过保持除雾器表面湿润,能够加强除雾器冲洗水的冲洗效果。

然而,上述研究并未考虑脱硫塔内烟气流场分布对除雾器除雾性能的影响,为此,本文基于某670 MW燃煤机组的脱硫塔,提出了一种新的流场优化方法,即利用导流板优化脱硫塔内的烟气速度场,消除除雾器入口截面的局部高速烟气区,以达到均匀分配除雾器工作负荷的目标,从而减缓甚至消除除雾器严重结垢堵塞的现象。

1 脱硫塔内流场对除雾器堵塞影响机理

1.1 烟气速度对喷淋浆液携带的影响

微细液滴在上升的烟气中主要受气流和重力的作用[7]。液滴所受重力为

对液滴受力应用二力平衡定理,可计算得到气流速度和液滴直径:

式(

1.2 烟气速度分布对垢体沉积的影响

2 脱硫塔及其进口烟道的流场优化

2.1 脱硫塔及其进口烟道中的烟气流场分布

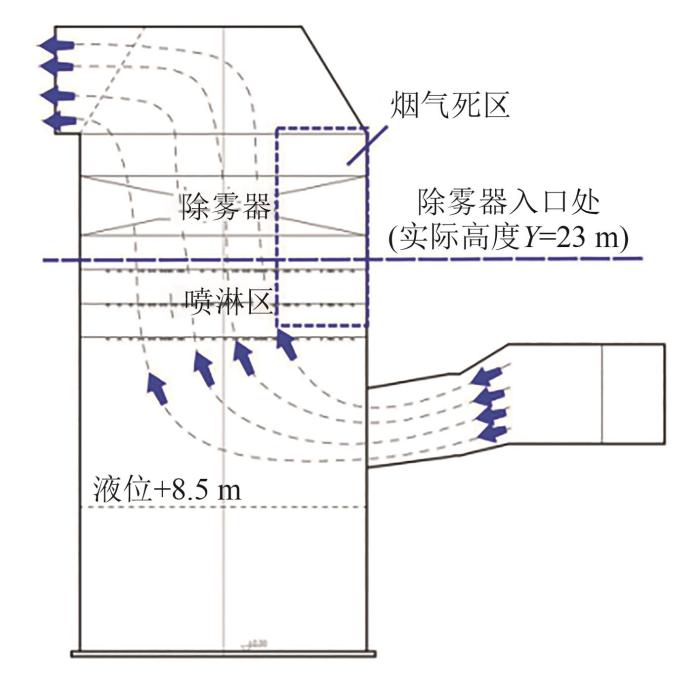

图1

图1

Z形脱硫塔的纵断面流场分布图

Fig. 1

Profile flow field distribution of Z-shaped desulfurization tower

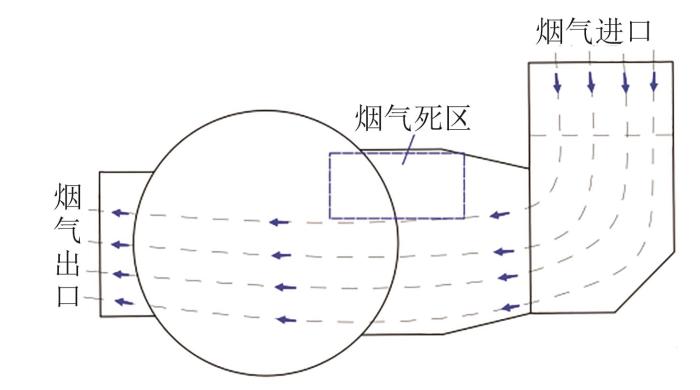

图2

图2

L形进口烟道的横断面流场分布图

Fig. 2

Cross section flow field distribution of L-shaped inlet flue

2.2 烟气流场优化方案

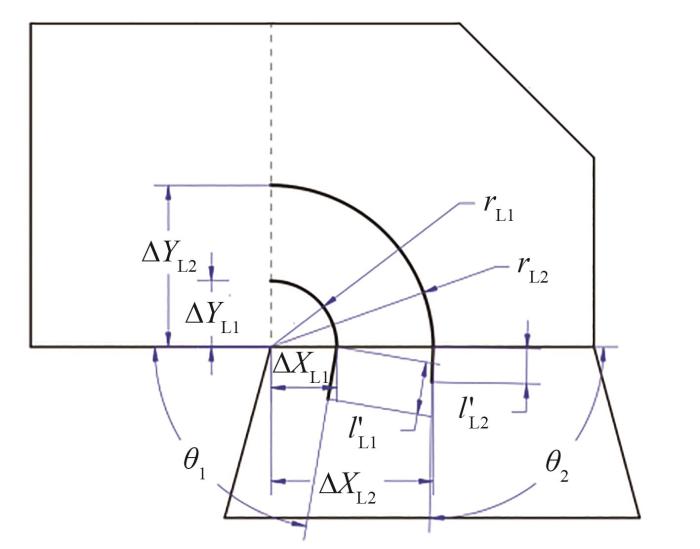

图3

图3

L形进口烟道导流板优化方案

Fig. 3

Optimization scheme of L-shaped inlet flue guide plate

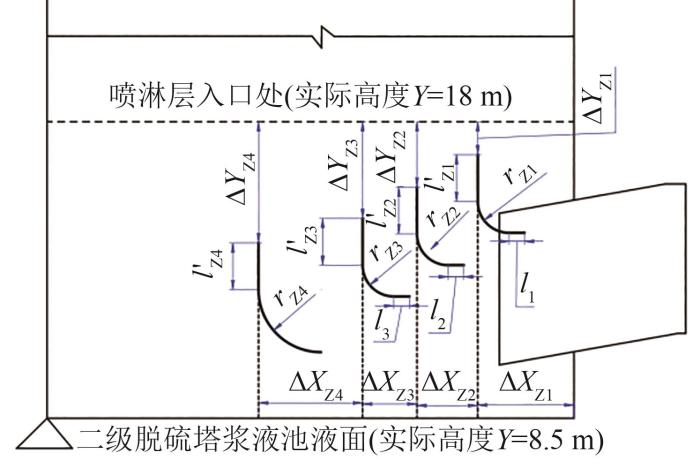

图4

图4

Z形脱硫塔内导流板优化方案

Fig. 4

Optimization scheme of guide plate in Z-shaped desulfurization tower

表1 导流板定形、定位尺寸

Tab. 1

| 三维模型 | 横向定位尺寸/m | 纵向定位尺寸/m | 横向定形尺寸/m | 纵向定形尺寸/m | 半径/m | 角度定位尺寸/(°) |

|---|---|---|---|---|---|---|

| L形进口烟道 | — | |||||

| Z形脱硫塔 | — |

3 烟气流场数值模拟

3.1 计算模型及边界条件

3.1.1 计算模型

3.1.2 网格划分及边界条件

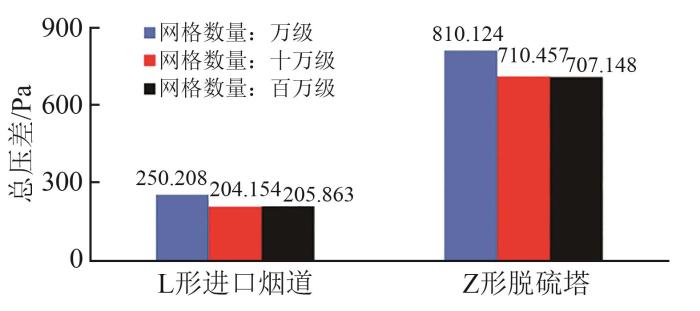

图5

图5

进出口总压差随网格数量的变化

Fig. 5

Change of total pressure difference between inlet and outlet with the number of grids

模型的入口边界条件为速度入口,出口边界条件为Outflow。具体的烟气参数如下:烟速为15 m/s,烟气密度为0.874 kg/m3,动力黏度为2.249×10-5 Pa⋅s,定压比热容为1.083 kJ/(kg⋅K)。脱硫塔内布置有3层喷淋管道,每层管道的喷嘴数量为84只,每只喷嘴的流量为14.38 kg/s,液滴的颗粒密度为1 140 kg/m3,喷嘴角度为90°,液滴粒径分布采用Rosin-Rammler分布函数[25]。

3.2 模拟结果与分析

3.2.1 流场分布

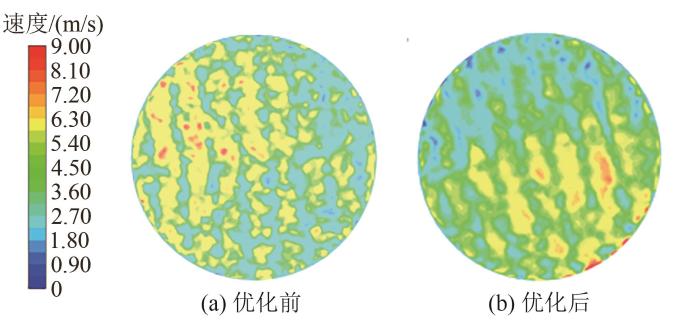

图6

图6

L形进口烟道Y=16 m截面上的速度云图

Fig. 6

Velocity map on cross section of L-shaped inlet flue at Y=16 m

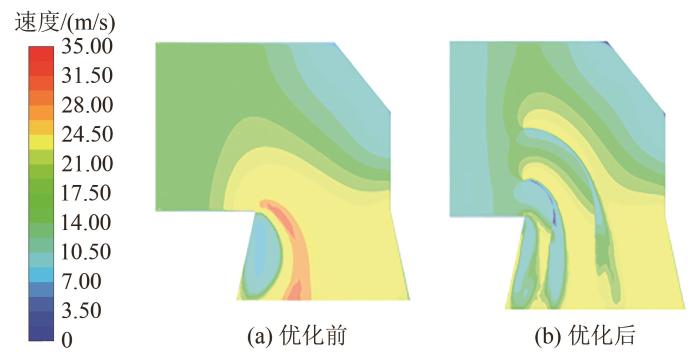

图7

图7

L形进口烟道出口截面上的速度云图

Fig. 7

Velocity map on exit cross section of L-shaped inlet flue

图8

图8

Z形脱硫塔Z=0 m截面上的速度云图

Fig. 8

Velocity map on cross section of Z-shaped desulfurization tower at Z=0 m

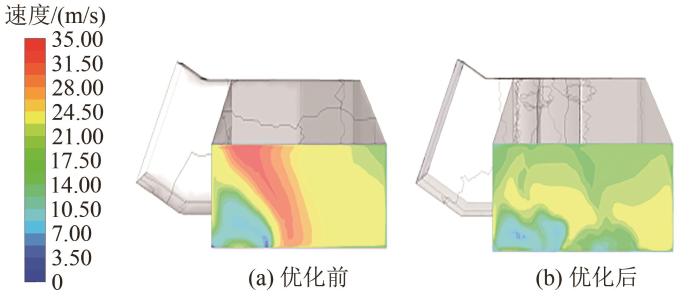

图9

图9

Z形脱硫塔Y=23 m截面上的速度云图

Fig. 9

Velocity map on cross section of Z-shaped desulfurization tower at Y=23 m

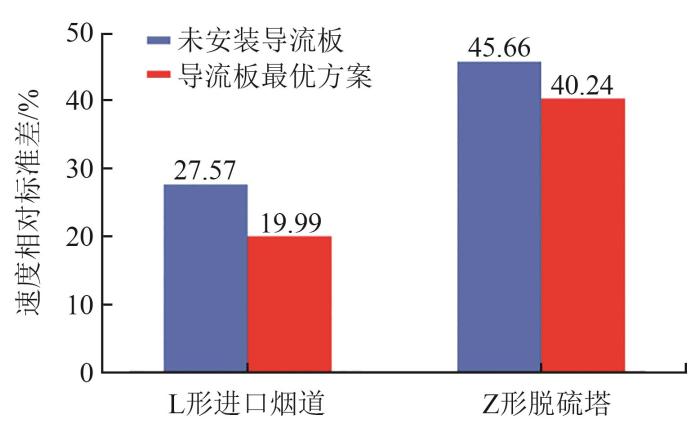

3.2.2 流场均匀性

图10

图10

L形进口烟道出口截面和Z形脱硫塔内除雾器入口截面的速度相对标准差

Fig. 10

Relative standard deviation of velocity of exit section of L-shaped inlet flue and entrance section of mist eliminator in Z-shaped desulphurization tower

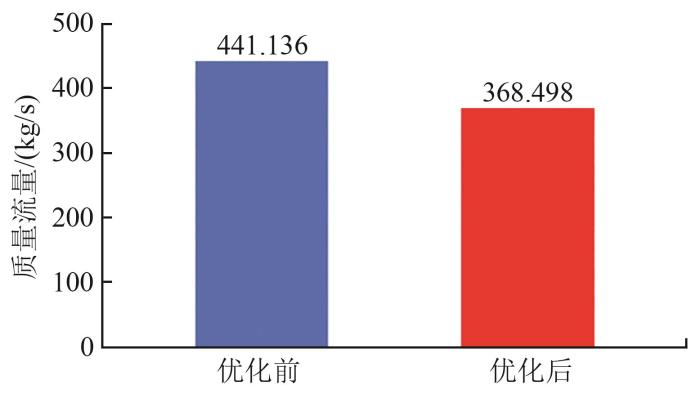

3.2.3 除雾器入口处的液滴质量流量

导致除雾器严重局部结垢甚至堵塞的原因主要是进入除雾器时烟气携带的浆液液滴过多。优化前后除雾器入口截面的浆液液滴质量流量如图11所示,可以看出,导流板优化后,除雾器入口截面的浆液液滴质量流量从原来的441.136 kg/s下降至368.498 kg/s,说明导流板能够明显地减少除雾器的工作负荷,大大降低其严重结垢堵塞的可能性。

图11

图11

优化前后除雾器入口截面的浆液液滴质量流量

Fig. 11

Mass flow rate of slurry droplets at inlet section of mist eliminator before and after optimization

4 工程实施与改造效果

4.1 改造对象及除雾器结垢情况

以该670 MW燃煤电厂的3号脱硫塔作为改造对象,该脱硫塔采用典型的Z形进出口布置,其进口烟道采用L形布置,平板式除雾器布置在脱硫塔的上方,烟气与吸收浆液采用逆流接触方式。改造前,该脱硫塔已经在额定负荷下运行了半年时间,其主要问题是:Z形脱硫塔内靠近出口附近的除雾器区域结垢严重,这与上述数值模拟得出的局部高速区位置基本吻合;此外,除雾器的迎风面结垢明显少于背风面,通过超声波测厚仪测得结垢厚度达到1 cm以上,除雾器冲洗水无法完全冲洗干净。

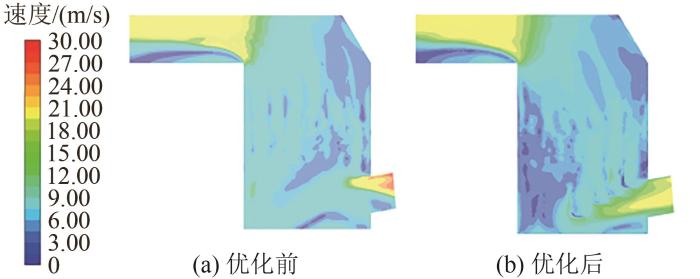

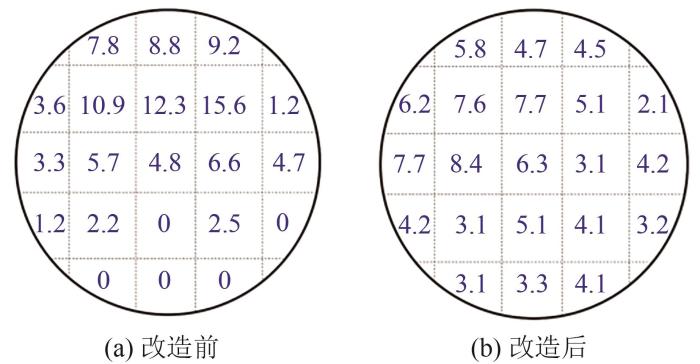

4.2 改造前后冷态实验

为了验证基于导流板优化塔内烟气流场的效果,分别于导流板安装前后在脱硫塔内进行冷态实验。具体步骤如下:在该脱硫塔的除雾器入口截面处(Y=23 m)设立若干个测点,当机组在额定工况下运行时,维持该负荷的风量不变,采用电子微压计测量并记录各点沿脱硫塔轴向的烟气速度。改造前后Z形脱硫塔除雾器入口截面烟气速度分布如图12所示,可以看出,改造前脱硫塔除雾器入口截面有的区域速度为0 m/s,改造后该区域速度提升至1~5 m/s。由此可见,实验结果与数值模拟计算得出的改造前后速度分布趋势基本一致,进一步说明了数值模拟结果的正确性和导流板的优化效果。

图12

图12

改造前后Z形脱硫塔除雾器入口截面烟气速度分布

Fig. 12

Flue gas velocity distribution at inlet cross section of mist eliminator of Z-shaped desulfurization tower before and after modification

4.3 实际工程改造效果

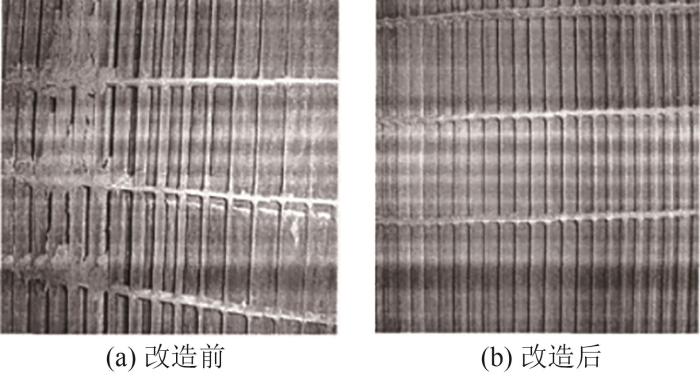

在进行脱硫塔改造时,对塔内除雾器板面上的垢体进行了彻底清洗。改造完成后,同样记录了在额定负荷下该脱硫塔180天的运行数据,结果发现,塔内除雾器前后压差不再超过200 Pa。在改造后的某一次停机维护中,测量得到除雾器板面上的结垢厚度从改造前的1 cm以上减小至0.1 cm左右,局部严重结垢堵塞的现象已完全消除,说明将本文优化方法应用于减缓除雾器结垢堵塞的效果显著。改造前后除雾器板面上的积垢情况如图13所示。

图13

图13

改造前后除雾器板面上的积垢情况

Fig. 13

Scale accumulation on mist eliminator plate before and after modification

5 结论

提出了一种利用导流板减缓脱硫塔除雾器堵塞的流场优化方法,对优化前后Z形脱硫塔及其L形进口烟道烟气流场进行了数值模拟分析,并将该方法应用于实际工程改造,得到以下结论:

1)在进口烟道和脱硫塔内合理布置导流板,可以显著消除脱硫塔内除雾器入口截面的烟气高速区。经过导流板优化后,L形进口烟道出口截面和Z形脱硫塔内除雾器入口截面的速度相对标准差均下降,除雾器入口截面的速度场明显比改造前更均匀。

2)基于导流板的流场优化方法能够明显减少冲击除雾器板面的液滴数量,大幅降低除雾器结垢程度,从而保证脱硫塔的安全稳定运行。

参考文献

火电厂烟塔合一技术应用现状与现存问题分析

[J].

Application status and existing problem analysis of the natural draft cooling towers with flue gas injection technology in thermal power plants

[J].

脱硫塔除雾器安装高度对烟气携液量影响的模拟研究

[J].

Simulation study on influence of installation height of mist eliminator on liquid holdup of flue gas in desulfurization tower

[J].

石灰石-石膏法脱硫系统除雾器堵塞研究

[J].

The study of demister blocking in limestone-gypsum desulfurization technology

[J].

石灰石-石膏湿法烟气脱硫除雾器堵塞分析与对策

[J].

Analysis and countermeasures of clogging in limestone-gypsum wet flue gas desulfurization mist eliminator

[J].

无GGH湿法脱硫系统除雾器堵塞原因及防堵建议

[J].

Analysis of causes of mist eliminators blockage in wet FGD systems without GGH and its countermeasures

[J].

折流板式除雾器的结垢与控制措施

[J].

Scaling and its control measure of chevron mist eliminator

[J].

喷淋层组合方式对大型脱硫塔内流动和热湿交换过程影响的数值模拟

[J].

Numerical simulation of impact of spraying layers scheme on gas-liquid two phases flow,heat and mass transfer in large scale desulphurization absorption tower

[J].

脱硫吸收塔除雾器性能的实验研究和数值模拟

[J].

Experimental study and numerical simulation of characteristics of demister of absorbing tower in desulfurization system

[J].

管束式除尘除雾器在脱硫串塔系统中的应用及性能评价

[J].

The application and performance evalution of bundle precipitator in series absorpti tower of desnifurization system

[J].

管束式除雾器结构优化数值模拟及高效除雾器研制

[J].

Numerical simulation on tube bundle demister and development of high efficiency demister

[J].

石灰石-石膏湿法脱硫吸收塔结垢分析及预防措施

[J].

Scaling analysis and preventive measures of limestone-gypsum wet flue gas desulfurization

[J].

Re-entrainment in wave-plate mist eliminators

[J].

Re-entrainment in and optimization of a vane mist eliminator

[J].

弯管二次流及电厂锅炉均流技术的研究进展

[J].

Research progress of secondary flow in bent pipe and flow sharing technology in power plant boiler

[J].

内置导流板的湿法脱硫塔数值模拟优化及应用

[J].

Numerical simulation optimization and application of wet desulfurization tower with inner guide plate

[J].

大功率充电连接器相变冷却换热特性研究

[J].

Study of phase change cooling heat transfer characteristics of high power charging connectors

[J].

多参数影响的导线热稳监测及动态增容研究

[J].

Thermal stability monitoring of conductor and dynamic line rating considering effects of multiple parameters

[J].

中深层U型对接井取热能力影响因素显著性分析

[J].

Significance analysis on the influence factors of thermal extraction capacity of medium-deep U-shaped butted well

[J].

适用于回流区流体力学模拟计算的三种高雷诺数湍流模型的比较

[J].

Comparison of three high-reynolds-number models in recirculation zones for simulation of computational fluid dynamics

[J].

壁面处理对壁面旋转旋流器流动模拟的影响分析

[J].

Analysis of effect of near-wall treatments on numerical computation of rotating hydrocyclone

[J].

壁面函数在超声速湍流模拟中的应用

[J].

Application of wall function to supersonic turbulence simulation

[J].

近壁面处理对湍流数值计算的影响分析

[J].

Analysis of effect of near-wall treatments on numerical computation of turbulent flow

[J].

湿法烟气脱硫吸收塔阻力特性实验研究

[J].

Experimental study on absorber resistance characteristic of WFGD

[J].

脱硫湿烟气喷淋冷凝过程中的参数优化研究

[J].

Study on parameter optimization of desulfurized wet flue gas in spray condensation process

[J].

湿法烟气脱硫喷淋塔的阻力特性研究

[J].

Research of resistance characteristics of wet flue gas desulfurization spraying scrubber

[J].