0 引言

1 袋式除尘器脱Hg原理分析

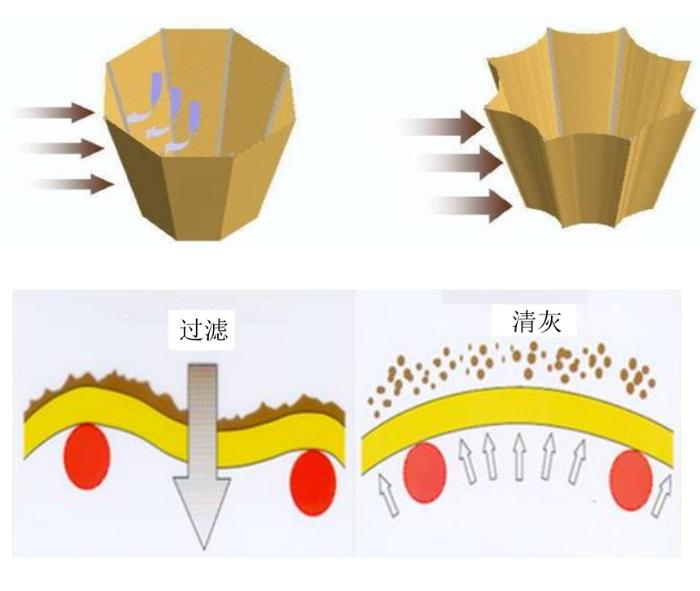

袋式除尘器的除尘主要依靠滤袋和笼骨组成的各单元过滤室,收尘和清灰工作原理如图1所示。含尘气体穿过滤布,粉尘颗粒会吸附并被截留在滤布外表面。在袋式除尘器工作时,随着过滤的不断进行,滤布外表面积聚的粉尘逐渐增多,布袋除尘器的阻力也随之增加。当达到设定阻力值时,清灰控制器发出清灰指令,脉冲阀会向滤袋内侧喷吹出压缩气体,滤袋内部的压力升高,滤布会在瞬间发生“鼓胀”,脱离笼骨表面,将滤袋外表面的粉尘清除下来,并落入灰斗,然后脉冲阀关闭,滤布在负压作用下又返回笼骨表面,恢复过滤收尘功能。

图1

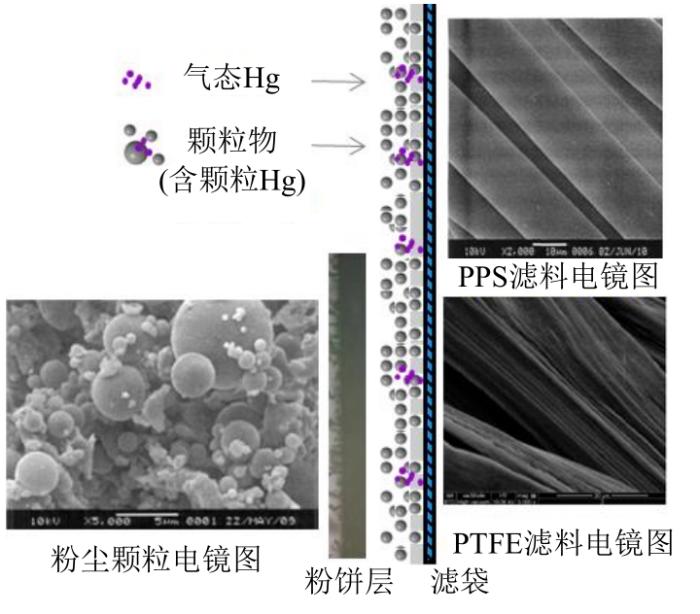

Hg按形态可分为颗粒Hg和气态Hg,按价态可分为Hg0和Hg2+,其中,Hg0绝大部分以气态形式存在,也是现有环保设备最难协同脱除的。袋式除尘器在高效除尘的同时会脱除绝大部分的颗粒Hg,滤袋表面沉积的一层粉饼层能加强飞灰与烟气的接触,延长含Hg烟气在飞灰表面的停留时间,有利于飞灰对烟气Hg的氧化与吸附。燃煤飞灰炭粒的多孔隙结构和巨大比表面积具有很强的过滤吸附效果[19],且飞灰中含有的未燃尽碳及CaO、Fe2O3等金属氧化物对烟气中的Hg0具有一定的氧化及吸附作用,这些都会进一步增强对烟气中Hg的吸附脱除效果。袋式除尘器的脱Hg机理如图2所示,PPS、PTFE等滤料表面致密、空隙小、过滤性能强,其表面形成的粉尘颗粒堆积层可有效吸附脱除烟气中各形态的Hg。

图2

2 袋式除尘器脱Hg效率分析

2.1 燃煤电厂袋式除尘器脱Hg效率分析

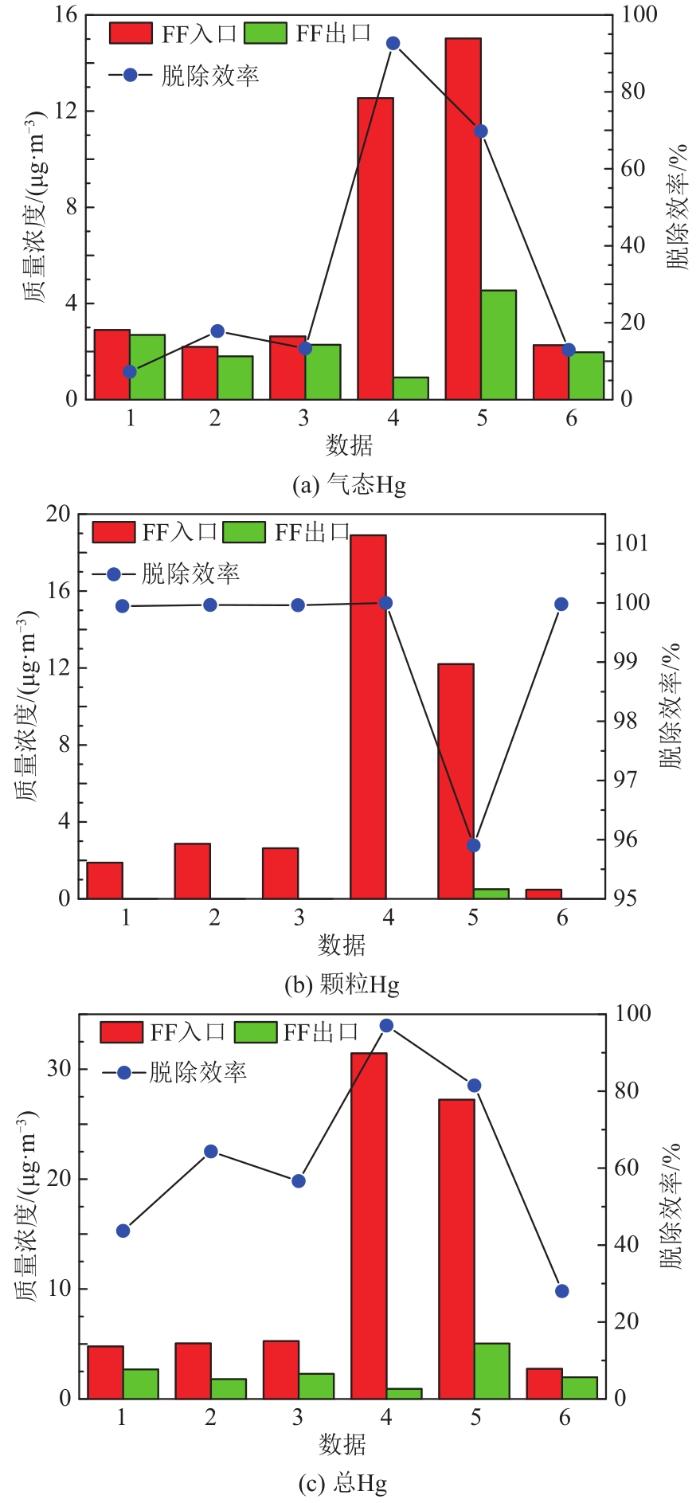

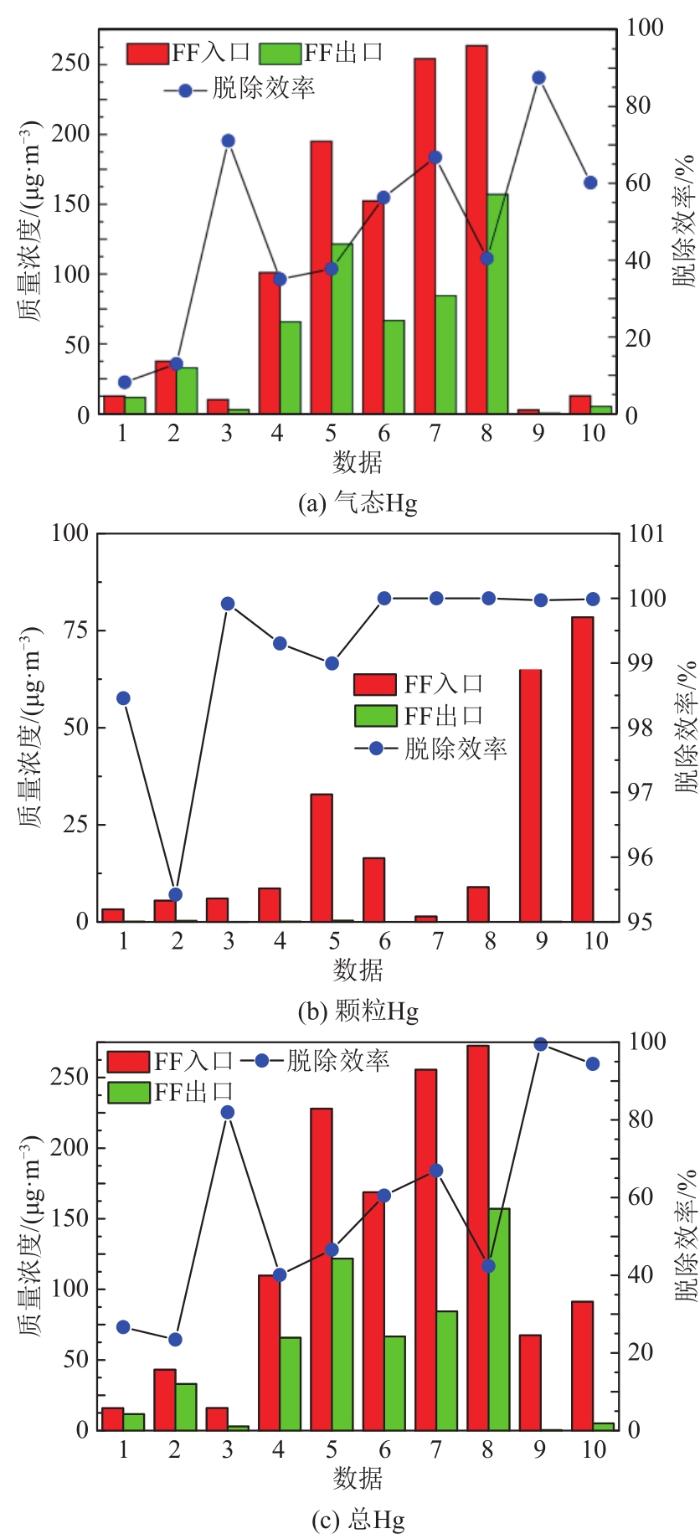

对6组燃煤电厂袋式除尘器脱Hg数据[20-23]进行整理分析,袋式除尘器对各类形态Hg的脱除效果如图3所示,其中:数据1、2、3分别为某350 MW机组在100%、85%和68%最大连续工况(maximum continuous rating,MCR)下测定结果;数据4、5、6分别为某430、50、80 MW机组的测定结果。由图3可见,不同机组对气态Hg的脱除效率差异较大,在7.24%~92.66%。一方面,脱除效率与袋式除尘器入口的气态Hg质量浓度有关,一般初始质量浓度越高,对应的脱除效率越高,如数据4、5对应袋式除尘器入口气态Hg质量浓度分别为12.54、15.02 μg/m3,对应的脱除效率分别为92.66%、69.77%;另一方面,推测脱除效率与飞灰中未燃尽碳的含量有关,这决定了滤袋表面粉饼层对气态Hg的吸附性能。袋式除尘器可脱除绝大部分的颗粒Hg,脱除效率在95.9%~100%。仅数据5对应的袋式除尘器出口颗粒Hg质量浓度为0.5 μg/m3,脱除效率为95.9%,而其他袋式除尘器出口几乎测不到颗粒Hg。这主要是因为数据5对应的袋式除尘器为2007年前投运使用,执行的Hg排放标准是50 mg/m3,因此颗粒物脱除性能较其他袋式除尘器低。袋式除尘器对总Hg的脱除效率在28.03%~97.07%。

图3

图3

燃煤电厂袋式除尘器脱Hg性能

Fig. 3

Hg removal performance of fabric filter in coal-fired power plant

2.2 燃煤电厂电袋复合除尘器脱Hg效率分析

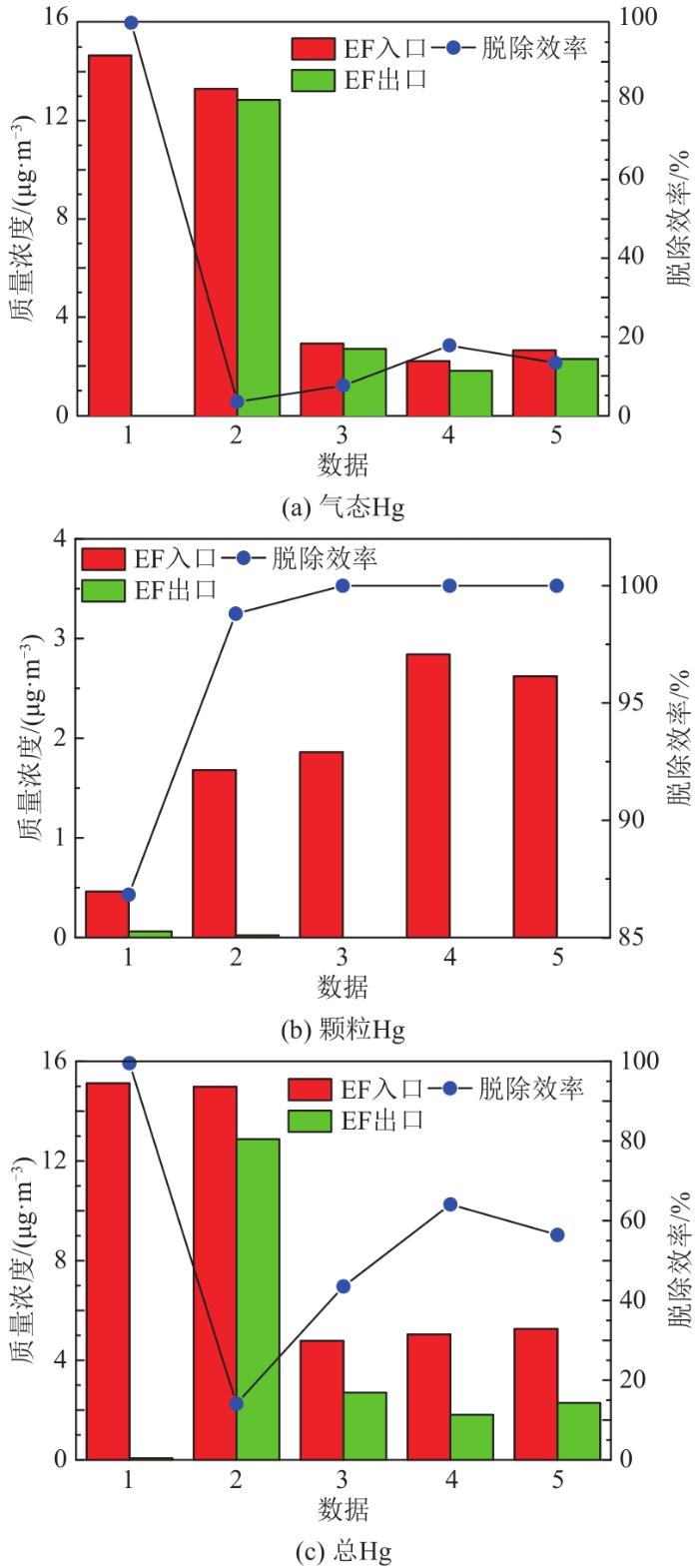

对5组燃煤电厂电袋复合除尘器脱Hg数据[24-26]进行整理分析,电袋复合除尘器对各类形态Hg的脱除效果如图4所示,其中:数据3、4、5分别为某350 MW机组在100%MCR、85%MCR和68%MCR下的测定结果;数据2为某300 MW机组测定结果;数据1的机组信息不详。由图4可见,不同机组对气态Hg的脱除效率差异较大,在3.38%~99.93%。电袋复合除尘器可脱除绝大部分的颗粒Hg,脱除效率在86.83%~100%,数据3、4、5对应的电袋复合除尘器出口颗粒Hg质量浓度均为0 μg/m3。电袋复合除尘器对总Hg的脱除效率在14.09%~99.52%。从现有数据来看,燃煤电厂袋式除尘器和电袋复合除尘器对各类形态Hg的脱除效果相当。

图4

图4

燃煤电厂电袋复合除尘器脱Hg性能

Fig. 4

Hg removal performance of electrostatic fabric filter in coal-fired power plant

2.3 水泥厂袋式除尘器脱Hg效率分析

图5

图5

水泥厂袋式除尘器脱Hg性能

Fig. 5

Hg removal performance of fabric filter in cement plant

由图5可见,不同机组对气态Hg的脱除效率差异较大,在8.17%~87.50%,对颗粒Hg的脱除效率在95.42%~100%,对总Hg的脱除效率在23.43%~99.48%。水泥厂烟气中Hg浓度普遍较高,尤其是生料磨离线运行时,如数据8为10号线生料磨离线时数据,其入口总Hg质量浓度超过270 μg/m3。从现有数据来看,水泥厂袋式除尘器对各类形态Hg的脱除效果略低于燃煤电厂,推测主要原因是其配置较燃煤电厂差。根据工程经验,燃煤电厂实施超低排放后,袋式除尘器出口颗粒质量浓度一般要求在10 mg/m3以下,此时袋式除尘器过滤风速选取一般不超过0.8 m/min。而水泥行业颗粒物排放执行的是30或20 mg/m3标准,过滤风速一般选取在0.9~1.0 m/min。同时,水泥窑袋式除尘器处理烟气温度较燃煤电厂高,水泥窑尾袋式除尘器处理烟气温度一般在100~180 ℃,高温甚至可瞬时达到260 ℃。而燃煤电厂处理烟气温度一般在120 ℃左右,飞灰中含有一定含量的残炭以及金属氧化物[29],加之其多孔隙结构和巨大比表面积有利于吸附脱除烟气中Hg,但物理吸附脱Hg性能与温度严格相关,温度越高,其吸附脱除性能下降越明显[30-31]。

3 袋式除尘器脱Hg效率实测

3.1 工程概况及试验方法

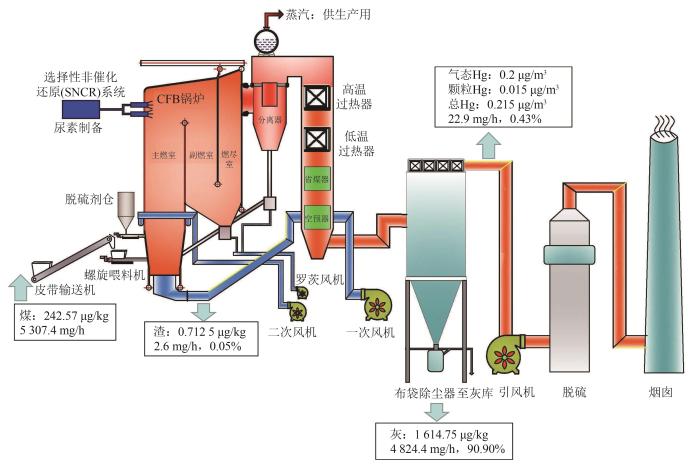

平湖独山港环保能源有限公司建设3台出力15 MW级的高温高压CB15型抽汽背压式热电机组,配置3台出力为180 t/h的高温高压(9.81 MPa/540 ℃)燃煤循环流化床(circulating fluidized bed,CFB)锅炉,掺烧污泥,同步建设脱硫脱硝及活性炭喷射设备,工艺流程如图6所示。

图6

对#1机组开展脱汞性能测试试验,试验期间仅烧煤,且活性炭喷射装置停运,以此考核袋式除尘器的协同脱汞性能。所用试验仪器设备如表1所示,测试方法符合标准GB/T 16157—1996《固定污染源排气中颗粒物测定与气态污染物采样方法》和HJ 917-2017《固定污染源废气 气态汞的测定 活性炭吸附/热裂解原子吸收分光光度法》的相关规定。采用ZR-3700A型烟气汞综合采样器分别在布袋除尘器进出口采集气态Hg样品,其中入口处在枪头增设防尘罩,以避免高尘浓度对活性炭管的污染。采集的气态Hg样品吸附在活性炭中,本次试验采用两段式的活性炭吸附管,其中第2段用于判定样品是否失效(透率≤10%)。烟气中的颗粒Hg主要通过烟尘样品中的Hg含量来测定,其中,烟尘采样采用崂应3012H自动烟尘采样仪、崂应1085B常规烟尘采样枪。煤、渣、飞灰样品经干燥、研磨、过筛等操作后制备分析样品,并采用RA-915F型高频塞曼直接测汞仪来定量分析样品中的汞含量。

表1 试验仪器

Tab. 1

| 序号 | 仪器名称 | 型号 | 规格 | 厂家 |

|---|---|---|---|---|

| 1 | 大气压力表 | Testo 622 | — | — |

| 2 | 烟尘采样仪 | 3012H | — | 青岛崂应 |

| 3 | 等速采样管 | — | 5 m | 青岛崂应 |

| 4 | 烟气测试仪 | 3022 | — | 青岛崂应 |

| 5 | 采样枪 | — | 加热120 ℃、除湿 | M&C |

| 6 | 电子天平 | AE-100 | 0.01 mg | 瑞士梅特勒 |

| 7 | 汞分析仪 | RA-915F | — | 鲁梅克斯 |

| 8 | 烟气汞综合采样器 | ZR-3700A | — | 青岛众瑞 |

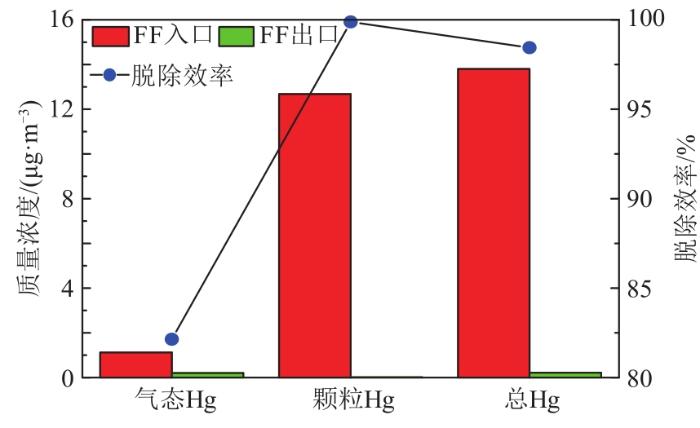

3.2 测试结果及分析

图7

对于Hg的输出量

式中:

定义Hg在各个输出单元的分布系数

式中

当

4 结论

1)根据机理分析,袋式除尘器在高效除尘的同时会脱除绝大部分的颗粒Hg,滤袋表面沉积的一层粉饼层对气态Hg等污染物也具有很强的过滤吸附效果。

2)燃煤电厂袋式除尘器对气态Hg的脱除效率差异较大,在7.24%~92.66%,推测主要是与入口气态Hg浓度和飞灰中未燃尽碳的含量有关,对颗粒Hg、总Hg的脱除效率分别在95.9%~100%和28.03%~97.07%;燃煤电厂电袋复合除尘器对各类形态Hg的脱除效果与袋式除尘器相当,对气态Hg、颗粒Hg、总Hg的脱除效率分别在3.38%~99.93%、86.83%~100%和14.09%~99.52%;水泥厂袋式除尘器对各类形态Hg的脱除效果略低于燃煤电厂,对气态Hg、颗粒Hg、总Hg的脱除效率分别在8.17%~87.5%、95.42%~100%和23.43%~99.48%。

3)根据工程实测,袋式除尘器对气态Hg、颗粒Hg和总Hg脱除效率分别为82.14%、99.88%和98.44%,经计算,炉渣、粉煤灰和烟气中Hg对应的分布系数分别为0.05%、90.90%和0.43%,主要集中在粉煤灰中,整个系统的平衡系数为91.38%,数据可信度较高。

参考文献

Hybrid air filters:a review of the main equipment configurations and results

[J].

我国袋式除尘行业技术新进展

[J].

New technology development of bag filters in China

[J].

2019年袋式除尘行业发展评述及展望

[J].

Review and prospect of the development of bag-hose precipitation industry in 2019 new technology development of bag filters in China

[J].

袋式除尘技术发展回顾和展望

[J].

Review and prospect of bag dust removal technology

[J].

2018年中国除尘器应用结构、袋式除尘器及静电除尘器发展现状分析

[EB/OL].(

Analysis of application structure,bag dust collector and electrostatic precipitator development status in China in 2018

[EB/OL].(

基于故障树分析法袋式除尘器滤袋失效的研究与应用

[J].

Study and application of bags’ failure in bag filter using fault tree analysis method

[J].

袋式除尘技术在我国燃煤电厂的推广应用

[J].

Popularization and application of bag hose precipitating technology in China coal-fired power plant

[J].

基于含尘烟气超低排放用袋式除尘滤料织物构造特性研究及应用

[D].

Research and application on characteristics of filter media with bag filter based on ultra low emission of dust-laden flue gas

[D].

Investigation of the pyrolysis behaviour of hybrid filter media for needle-punched nonwoven bag filters

[J].

高温除尘用金属纤维滤料的性能研究

[J].

Study on the performance of metal fiber filter for high temperature dust removal

[J].

燃煤电厂烟气中Hg的生成、治理、测试及排放特征研究火电厂

[J].

Study on generation,treatment,testing and emission characteristics of Hg in flue gas of coal-fired power plants

[J].

Using modified fly ash for mercury emissions control for coal-fired power plant applications in China

[J].

Trace element (Hg,As,Cr,Cd,Pb) distribution and speciation in coal-fired power plants

[J].

燃煤电厂烟气Hg排放特征及其吸附脱除技术研究进展

[J].

Study on Hg emission characteristics and mercury adsorption removal technology of flue gas in coal-fired power plants

[J].

Study on the mercury captured by mechanochemical and bromide surface modification of coal fly ash

[J].

改性燃煤飞灰吸附氧化脱汞机理研究进展

[J].

Research progress of mercury adsorption and oxidation mechanism on modified coal-fired fly ash

[J].

Temporal trend and spatial distribution of speciated atmospheric mercury emissions in China during 1978-2014

[J].

燃煤烟气污染物控制装置协同脱汞特性研究

[J].

Characteristics of the existing air pollutant control devices on Hg synergistic removal in a coal-fired power plant

[J].

Characteristics and composition of fly ash from Canadian coal-fired power plants

[J].

Mercury speciation and mass distribution of coal-fired power plants in Taiwan using different air pollution control processes

[J].

不同超低排放技术路线的燃煤电站汞脱除研究

[J].

Removing mercury from flue gas of coal-fired power plants by different ultra-low emission technical routes

[J].

燃煤电站布袋除尘器和静电除尘器脱汞性能比较

[J].

Comparison of mercury removal characteristic between fabric filter and electrostatic precipitators of coal-fired power plants

[J].

燃煤烟气常规污染物净化设施协同控制汞的研究

[J].

Research on mercury collaborative control by conventional pollutants purification facilities of coal-fired power plants

[J].

基于实测的电袋复合除尘器脱除多污染物效果

[J].

Removal of multi-pollutants from coal-fired flue gas by electrostatic-fabric integrated precipitator based on field tests

[J].

350 MW超低排放燃煤电厂汞排放特性试验研究

[D].

Experimental study on mercury emission characteristics of 350 MW ultra-low emission coal-fired power plant

[D].

基于实测的燃煤电厂汞迁移转化规律研究分析

[J].

Study and analysis of mercury migration and transformation from coal-fired power plants based on field tests

[J].

水泥生产过程中汞的排放特征及减排潜力研究

[D].

Study on mercury emission characteristics and emission reduction potential in cement production

[D].

水泥生产线布袋除尘器和静电除尘器脱汞性能比较

[J].

Comparison of mercury removal performance between cloth bag dust collector and electrostatic dust collector in cement production line

[J].

Removal of elemental mercury in flue gas by Cu-Fe modified magnetosphere from coal combustion fly ash

[J].

喷射点位及温度对超低排放电厂活性炭吸附脱汞的影响

[J].

Effects of temperature and residence time on mercury control using activated carbon injection in ultra-low emission coal-fired power plant

[J].

煤粉炉和循环流化床锅炉飞灰吸附汞动力学及其吸附机制

[J].

Kinetics and mechanism of mercury adsorption on fly ashes from pulverized coal boiler and circulating fluidized bed boiler

[J].

淮南燃煤电厂汞分配、富集与释放通量

[J].

Distribution and enrichment of mercury in utility boiler of Huainan coal-fired power plant

[J].

Speciation of mercury in FGD gypsum and mercury emission during the wallboard production in China

[J].