发电技术 ›› 2024, Vol. 45 ›› Issue (5): 941-950.DOI: 10.12096/j.2096-4528.pgt.23123

• 发电及环境保护 • 上一篇

吕嘉伟, 霍兆义, 刘峰, 谢宁, 王文静

收稿日期:2023-10-07

修回日期:2023-11-25

出版日期:2024-10-31

发布日期:2024-10-29

作者简介:基金资助:Jiawei LÜ, Zhaoyi HUO, Feng LIU, Ning XIE, Wenjing WANG

Received:2023-10-07

Revised:2023-11-25

Published:2024-10-31

Online:2024-10-29

Supported by:摘要:

目的 基于㶲经济发展而来的高级㶲经济分析方法,能够细化拆分系统组件的经济成本,深入探究经济成本形成的内在原因。 方法 在结合高级㶲分析的基础上,采用高级㶲经济分析法将燃气-蒸汽联合循环发电系统中各组件的成本拆解为内源性成本、外源性成本、可避免成本和不可避免成本,并对此进行计算。 结果 在设计工况下,联合循环发电系统中燃烧室的可避免㶲损最大,为28.41 MW,占燃烧室㶲损的26.55%。基于计算结果,对透平提出了不同的改进措施,降低了系统内源性和外源性㶲损。系统中㶲耗散成本占比最大的是内源性可避免部分,底循环改进优先级最高的是高压缸,其次是低压缸。联合循环发电系统中年度化成本外源性占比为80.59%,其中外源性可避免部分占比40.04%。 结论 研究成果可为系统提供多方面能效评价角度和优化成本的改进方向。

中图分类号:

吕嘉伟, 霍兆义, 刘峰, 谢宁, 王文静. 燃气-蒸汽联合循环发电系统高级㶲经济性分析[J]. 发电技术, 2024, 45(5): 941-950.

Jiawei LÜ, Zhaoyi HUO, Feng LIU, Ning XIE, Wenjing WANG. Advanced Exergoeconomics Analysis of Gas-Steam Combined Cycle Power Generation System[J]. Power Generation Technology, 2024, 45(5): 941-950.

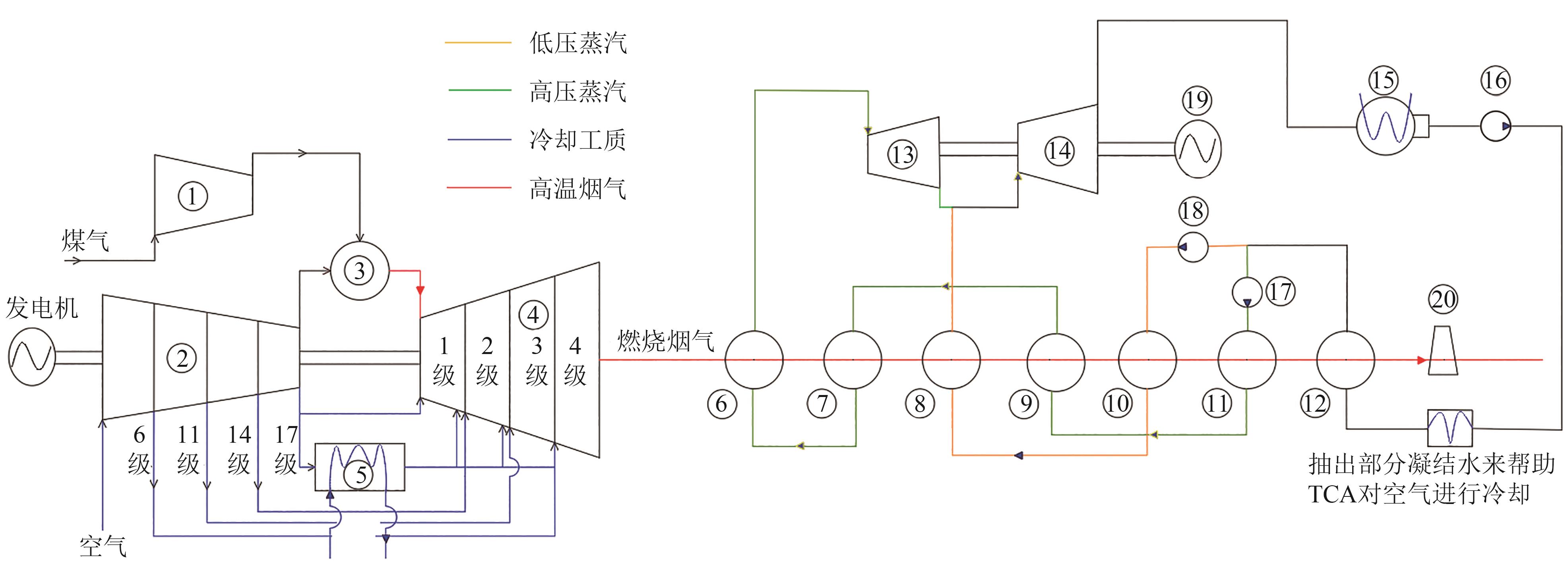

图1 燃气-蒸汽联合循环发电系统图①煤压机;②空压机;③燃烧室;④透平;⑤TCA;⑥高压过热器;⑦高压蒸发器;⑧低压过热器;⑨高压省煤器2;⑩低压蒸发器;⑪高压省煤器1;⑫除氧器;⑬汽轮机高压缸;⑭汽轮机低压缸;⑮凝汽器;⑯凝结泵;⑰高压泵;⑱低压泵;⑲发电机;⑳烟囱。

Fig. 1 Diagram of gas-steam combined cycle power generation system

| 参数 | 设计值 | 模拟值 |

|---|---|---|

| 系统发电量/MW | 150.00 | 150.79 |

| 高压蒸汽压力/MPa | 5.99 | 5.99 |

| 高压蒸汽温度/℃ | 510.00 | 512.00 |

| 高压蒸汽质量流量/(kg/s) | 45.00 | 48.74 |

| 低压蒸汽压力/MPa | 0.93 | 0.93 |

| 低压蒸汽温度/℃ | 260.00 | 268.12 |

| 低压蒸汽质量流量/(kg/s) | 13.00 | 13.20 |

| 燃气轮机排气温度/℃ | 520.00 | 525.99 |

| 燃气轮机排气质量流量/(kg/s) | 450.00 | 453.10 |

表1 联合循环发电系统主要设计参数

Tab. 1 Main design parameters of combined cycle power generation systems

| 参数 | 设计值 | 模拟值 |

|---|---|---|

| 系统发电量/MW | 150.00 | 150.79 |

| 高压蒸汽压力/MPa | 5.99 | 5.99 |

| 高压蒸汽温度/℃ | 510.00 | 512.00 |

| 高压蒸汽质量流量/(kg/s) | 45.00 | 48.74 |

| 低压蒸汽压力/MPa | 0.93 | 0.93 |

| 低压蒸汽温度/℃ | 260.00 | 268.12 |

| 低压蒸汽质量流量/(kg/s) | 13.00 | 13.20 |

| 燃气轮机排气温度/℃ | 520.00 | 525.99 |

| 燃气轮机排气质量流量/(kg/s) | 450.00 | 453.10 |

| 序号 | 温度/ ℃ | 压力/ MPa | 质量流量/ (kg·s-1) | 比焓/ (kJ·kg-1) | 熵/ [kJ/(kg·K)] |

|---|---|---|---|---|---|

| 1 | 25.00 | 101.09 | 127.25 | 33.83 | 7.45 |

| 2 | 426.80 | 1 636.40 | 127.25 | 611.60 | 7.65 |

| 3 | 25.00 | 101.09 | 252.02 | 32.87 | 8.87 |

| 4 | 122.45 | 258.49 | 1.81 | 355.22 | 8.97 |

| 5 | 234.51 | 565.22 | 15.05 | 473.68 | 8.99 |

| 6 | 398.80 | 1 445.30 | 58.29 | 608.15 | 9.00 |

| 7 | 398.80 | 1 445.30 | 176.87 | 608.15 | 9.00 |

| 8 | 1 250.60 | 1 416.40 | 355.94 | 1 944.60 | 9.83 |

| 9 | 398.80 | 1 445.30 | 34.37 | 608.15 | 9.00 |

| 10 | 671.95 | 1 445.30 | 23.93 | 608.15 | 9.00 |

| 11 | 200.00 | 1 445.30 | 23.93 | 266.36 | 8.43 |

| 12 | 525.99 | 103.35 | 453.10 | 725.57 | 9.87 |

| 13 | 467.22 | 101.09 | 453.10 | 402.35 | 9.39 |

| 14 | 293.12 | 101.09 | 453.10 | 394.19 | 9.37 |

| 15 | 288.13 | 101.09 | 453.10 | 356.81 | 9.31 |

| 16 | 250.81 | 101.09 | 453.10 | 264.31 | 9.12 |

| 17 | 194.88 | 101.09 | 453.10 | 193.01 | 8.96 |

| 18 | 146.35 | 101.09 | 453.10 | 157.73 | 8.87 |

| 19 | 117.32 | 101.09 | 453.10 | 134.36 | 8.83 |

| 20 | 278.12 | 5 990.40 | 48.74 | 2 782.40 | 5.87 |

| 21 | 512.88 | 5 990.40 | 48.74 | 3 393.00 | 6.83 |

| 22 | 268.12 | 5 990.40 | 48.74 | 1 174.00 | 2.95 |

| 23 | 268.12 | 930.00 | 13.20 | 2 983.10 | 7.00 |

| 24 | 179.88 | 930.00 | 13.20 | 2 776.20 | 6.58 |

| 25 | 198.14 | 5 990.40 | 48.74 | 918.39 | 2.46 |

| 26 | 102.32 | 930.00 | 13.20 | 428.85 | 1.33 |

| 27 | 102.32 | 110.00 | 13.20 | 428.85 | 1.33 |

| 28 | 102.32 | 110.00 | 48.74 | 428.85 | 1.33 |

| 29 | 102.32 | 5 990.40 | 48.74 | 428.85 | 1.33 |

| 30 | 286.00 | 930.00 | 48.74 | 2 983.70 | 7.04 |

| 31 | 304.55 | 4.70 | 61.94 | 2 305.70 | 7.59 |

| 32 | 20.00 | 101.00 | 3 097.10 | 83.95 | 0.30 |

| 33 | 30.96 | 101.00 | 3 097.10 | 129.31 | 0.45 |

| 34 | 31.80 | 4.70 | 61.94 | 133.19 | 0.46 |

| 35 | 31.00 | 1 420.00 | 61.94 | 133.29 | 0.46 |

| 36 | 80.00 | 1 420.00 | 61.94 | 258.53 | 0.85 |

表2 系统各主要节点的热力参数

Tab. 2 Thermal parameters of main nodes in the system

| 序号 | 温度/ ℃ | 压力/ MPa | 质量流量/ (kg·s-1) | 比焓/ (kJ·kg-1) | 熵/ [kJ/(kg·K)] |

|---|---|---|---|---|---|

| 1 | 25.00 | 101.09 | 127.25 | 33.83 | 7.45 |

| 2 | 426.80 | 1 636.40 | 127.25 | 611.60 | 7.65 |

| 3 | 25.00 | 101.09 | 252.02 | 32.87 | 8.87 |

| 4 | 122.45 | 258.49 | 1.81 | 355.22 | 8.97 |

| 5 | 234.51 | 565.22 | 15.05 | 473.68 | 8.99 |

| 6 | 398.80 | 1 445.30 | 58.29 | 608.15 | 9.00 |

| 7 | 398.80 | 1 445.30 | 176.87 | 608.15 | 9.00 |

| 8 | 1 250.60 | 1 416.40 | 355.94 | 1 944.60 | 9.83 |

| 9 | 398.80 | 1 445.30 | 34.37 | 608.15 | 9.00 |

| 10 | 671.95 | 1 445.30 | 23.93 | 608.15 | 9.00 |

| 11 | 200.00 | 1 445.30 | 23.93 | 266.36 | 8.43 |

| 12 | 525.99 | 103.35 | 453.10 | 725.57 | 9.87 |

| 13 | 467.22 | 101.09 | 453.10 | 402.35 | 9.39 |

| 14 | 293.12 | 101.09 | 453.10 | 394.19 | 9.37 |

| 15 | 288.13 | 101.09 | 453.10 | 356.81 | 9.31 |

| 16 | 250.81 | 101.09 | 453.10 | 264.31 | 9.12 |

| 17 | 194.88 | 101.09 | 453.10 | 193.01 | 8.96 |

| 18 | 146.35 | 101.09 | 453.10 | 157.73 | 8.87 |

| 19 | 117.32 | 101.09 | 453.10 | 134.36 | 8.83 |

| 20 | 278.12 | 5 990.40 | 48.74 | 2 782.40 | 5.87 |

| 21 | 512.88 | 5 990.40 | 48.74 | 3 393.00 | 6.83 |

| 22 | 268.12 | 5 990.40 | 48.74 | 1 174.00 | 2.95 |

| 23 | 268.12 | 930.00 | 13.20 | 2 983.10 | 7.00 |

| 24 | 179.88 | 930.00 | 13.20 | 2 776.20 | 6.58 |

| 25 | 198.14 | 5 990.40 | 48.74 | 918.39 | 2.46 |

| 26 | 102.32 | 930.00 | 13.20 | 428.85 | 1.33 |

| 27 | 102.32 | 110.00 | 13.20 | 428.85 | 1.33 |

| 28 | 102.32 | 110.00 | 48.74 | 428.85 | 1.33 |

| 29 | 102.32 | 5 990.40 | 48.74 | 428.85 | 1.33 |

| 30 | 286.00 | 930.00 | 48.74 | 2 983.70 | 7.04 |

| 31 | 304.55 | 4.70 | 61.94 | 2 305.70 | 7.59 |

| 32 | 20.00 | 101.00 | 3 097.10 | 83.95 | 0.30 |

| 33 | 30.96 | 101.00 | 3 097.10 | 129.31 | 0.45 |

| 34 | 31.80 | 4.70 | 61.94 | 133.19 | 0.46 |

| 35 | 31.00 | 1 420.00 | 61.94 | 133.29 | 0.46 |

| 36 | 80.00 | 1 420.00 | 61.94 | 258.53 | 0.85 |

| 序号 | 组件 | MW | MW | MW | MW |

|---|---|---|---|---|---|

| 1 | AC | 4.03 | 5.15 | 2.16 | 8.06 |

| 2 | GC | 4.21 | 1.17 | 2.02 | 3.58 |

| 3 | CC | 97.98 | 7.08 | 78.59 | 28.41 |

| 4 | TU | 15.45 | 6.00 | 13.43 | 8.86 |

| 5 | TCA | 0.59 | 5.53 | 6.52 | 1.52 |

| 6 | Con | 2.29 | 0.35 | 2.23 | 0.41 |

| 7 | HPST | 2.49 | 0.27 | 1.21 | 1.64 |

| 8 | LPST | 9.18 | 0.69 | 4.35 | 6.06 |

| 9 | Hsup | 2.57 | 0.26 | 2.01 | 0.82 |

| 10 | Heva | 3.59 | 2.34 | 3.95 | 2.03 |

| 11 | Lsup | 0.14 | 0.02 | 0.12 | 0.05 |

| 12 | Heco2 | 0.22 | 0.14 | 0.11 | 0.16 |

| 13 | Leva | 1.82 | 0.03 | 1.64 | 0.63 |

| 14 | Heco1 | 0.17 | 0.18 | 0.18 | 0.03 |

| 15 | Dea | 1.28 | 0.25 | 1.23 | 0.19 |

表3 联合循环发电系统各组件高级㶲损

Tab. 3 Advanced exergy for all components of the system

| 序号 | 组件 | MW | MW | MW | MW |

|---|---|---|---|---|---|

| 1 | AC | 4.03 | 5.15 | 2.16 | 8.06 |

| 2 | GC | 4.21 | 1.17 | 2.02 | 3.58 |

| 3 | CC | 97.98 | 7.08 | 78.59 | 28.41 |

| 4 | TU | 15.45 | 6.00 | 13.43 | 8.86 |

| 5 | TCA | 0.59 | 5.53 | 6.52 | 1.52 |

| 6 | Con | 2.29 | 0.35 | 2.23 | 0.41 |

| 7 | HPST | 2.49 | 0.27 | 1.21 | 1.64 |

| 8 | LPST | 9.18 | 0.69 | 4.35 | 6.06 |

| 9 | Hsup | 2.57 | 0.26 | 2.01 | 0.82 |

| 10 | Heva | 3.59 | 2.34 | 3.95 | 2.03 |

| 11 | Lsup | 0.14 | 0.02 | 0.12 | 0.05 |

| 12 | Heco2 | 0.22 | 0.14 | 0.11 | 0.16 |

| 13 | Leva | 1.82 | 0.03 | 1.64 | 0.63 |

| 14 | Heco1 | 0.17 | 0.18 | 0.18 | 0.03 |

| 15 | Dea | 1.28 | 0.25 | 1.23 | 0.19 |

| 1 | 张金良,贾凡 .中国火电行业多模型碳达峰情景预测[J].电力建设,2022,43(5):18-28. doi:10.12204/j.issn.1000-7229.2022.05.003 |

| ZHANG J L, JIA F .Multi-model carbon peak scenario prediction for thermal power industry in China[J].Electric Power Construction,2022,43(5):18-28. doi:10.12204/j.issn.1000-7229.2022.05.003 | |

| 2 | 张全斌,周琼芳 .基于“双碳” 目标的中国火力发电技术发展路径研究[J].发电技术,2023,44(2):143-154. doi:10.12096/j.2096-4528.pgt.22092 |

| ZHANG Q B, ZHOU Q F .Research on the development path of China’s thermal power generation technology based on the goal of “carbon peak and carbon neutralization”[J].Power Generation Technology,2023,44(2):143-154. doi:10.12096/j.2096-4528.pgt.22092 | |

| 3 | 臧紫坤,杨晓辉,李昭辉,等 .考虑储热改造与最优弃能的风光火储低碳经济调度[J].电力系统保护与控制,2022,50(12):33-43. |

| ZANG Z K, YANG X H, LI Z H,et al .Low-carbon economic scheduling of solar thermal storage considering heat storage transformation and optimal energy abandonment[J].Power System Protection and Control,2022,50(12):33-43. | |

| 4 | 梁中荣,蓝茂蔚,郑国,等 .基于最小二乘支持向量机的电站锅炉高效率低NO x 的多目标优化研究[J].发电技术,2023,44(6):809-816. doi:10.12096/j.2096-4528.pgt.22108 |

| LIANG Z R, LAN M W, ZHENG G,et al .Study on multi-objective optimization of high-efficiency and low-NO x emissions of power station boilers based on least squares support vector machines[J].Power Generation Technology,2023,44(6):809-816. doi:10.12096/j.2096-4528.pgt.22108 | |

| 5 | 冯凌杰,翟融融,郭一村,等 .耦合碳捕集系统的燃气蒸汽联合循环综合性能研究[J].发电技术,2022,43(4):584-592. doi:10.12096/j.2096-4528.pgt.22077 |

| FENG L J, ZHAI R R, GUO Y C,et al .Study on the comprehensive performance of natural gas combined cycle plant integrated with carbon capture system[J].Power Generation Technology,2022,43(4):584-592. doi:10.12096/j.2096-4528.pgt.22077 | |

| 6 | 张赢,张国罡,邹健 .南方地区大型二次循环燃气-蒸汽联合循环调峰机组满足用水定额设计思路探讨[J].南方能源建设,2022,9(S1):43-49. |

| ZHANG Y, ZHANG G G, ZOU J .Discussion on the design idea of meeting the water consumption quota of large-scale secondary cycle gas-steam combined cycle peak shaving unit in Southern China[J].Southern Energy Construction,2022,9(S1):43-49. | |

| 7 | 林孙奔,唐琦雯,徐立中,等 .基于独立建模的分轴燃机参与电力现货市场机制[J].浙江电力,2022,41(9):22-28. |

| LIN S B, TANG Q W, XU L Z,et al .A mechanism based on independent modeling for split-shaft gas turbines participating in power spot market[J].Zhejiang Electric Power,2022,41(9):22-28. | |

| 8 | 侯建军,付喜亮,李染生,等 .基于㶲分析的能量梯级利用供热变工况运行优化研究[J].中国电力,2023,56(8):230-240. |

| HOU J J, FU X L, LI R S,et al .Research on operation optimization of energy cascade utilization heating based on exergy analysis[J].Electric Power,2023,56(8):230-240. | |

| 9 | 赵宝玲,任强,董昌伟,等 .150 MW燃气蒸汽联合循环机组热力学分析[J].节能,2017,36(11):27-30. doi:10.3969/j.issn.1004-7948.2017.11.007 |

| ZHAO B L, REN Q, DONG C W,et al .Thermodynamic analysis of 150 MW gas-steam combined cycle units[J].Energy Conservation,2017,36(11):27-30. doi:10.3969/j.issn.1004-7948.2017.11.007 | |

| 10 | 孔羽,马欢,司风琪,等 .基于灯用分析的燃气-蒸汽联合循环机组变工况研究[J].能源研究与利用,2016(3):21-26. doi:10.3969/j.issn.1001-5523.2016.03.013 |

| KONG Y, MA H, SI F Q,et al .Study on off-design condition of gas-steam combined cycle unit based on lamp analysis[J].Energy Research & Utilization,2016(3):21-26. doi:10.3969/j.issn.1001-5523.2016.03.013 | |

| 11 | ERSAYIN E, OZGENER L .Performance analysis of combined cycle power plants:A case study[J].Renewable and Sustainable Energy Reviews,2015:43. doi:10.1016/j.rser.2014.11.082 |

| 12 | 付忠广,王霄楠,卢可,等 .燃气预热温度对燃气-蒸汽联合循环性能影响[J].热力发电,2016,45(10):16-22. doi:10.3969/j.issn.1002-3364.2016.10.016 |

| FU Z G, WANG X N, LU K,et al .Influence of preheating temperature of nature gas on performance of gas-stem combined cycle[J].Thermal Power Generation,2016,45(10):16-22. doi:10.3969/j.issn.1002-3364.2016.10.016 | |

| 13 | 张振东,唐佑宁,伍卓汉 .基于天然气联合循环发电厂CO2捕集与选择性废气再循环的Exergy分析[J].华南师范大学学报(自然科学版),2023,55(3):1-8. |

| ZHANG Z D, TANG Y N, WU Z H .Exergy analysis based on CO2 capture and selective exhaust gas recirculation in a natural gas combined cycle power plant[J].Journal of South China Normal University (Natural Science Edition),2023,55(3):1-8. | |

| 14 | 王光烛,陈坚红,洪细良,等 .联合循环发电系统全生命周期㶲环境学评估[J].浙江大学学报(工学版),2019,53(5):972-980. |

| WANG G Z, CHEN J H, HONG X L,et al .Exergoenvironmental evaluation for combined cycle power generation system based on life cycle assessment[J].Journal of Zhejiang University (Engineering Science),2019,53(5):972-980. | |

| 15 | 吴捷,马斌 .燃气-蒸汽联合循环发电系统环境影响生命周期研究[J].石油和化工设备,2011,14(8):71-74. doi:10.3969/j.issn.1674-8980.2011.08.022 |

| WU J, MA B .Study on life cycle of environmental impact of gas-steam combined cycle power generation system[J].Petro & Chemical Equipment,2011,14(8):71-74. doi:10.3969/j.issn.1674-8980.2011.08.022 | |

| 16 | 洪细良 .基于全生命周期的燃煤与天然气发电系统改进的㶲环境学分析与评价[D].杭州:浙江大学,2018. |

| HONG X L .Advanced exergoenvironmental analyse and evaluation for coal-fired and natural gas-fired power plants based on life cycle assessment[D].Hangzhou:Zhejiang University,2018. | |

| 17 | BONFORTE G, BUCHGEISTER J, MANFRIDA G,et al .Exergoeconomic and exergoenvironmental analysis of an integrated solar gas turbine/combined cycle power plant[J].Energy,2018,156:352-359. doi:10.1016/j.energy.2018.05.080 |

| 18 | GU H, CUI X, ZHU H,et al .Multi-objective optimization analysis on gas-steam combined cycle system with exergy theory[J].Journal of Cleaner Production,2021,278:123939. doi:10.1016/j.jclepro.2020.123939 |

| 19 | TAJIK MANSOURI M, AHMADI P, GANJEH KAVIRI A,et al .Exergetic and economic evaluation of the effect of HRSG configurations on the performance of combined cycle power plants[J].Energy Conversion and Management,2012,58:47-58. doi:10.1016/j.enconman.2011.12.020 |

| 20 | TALEBIZADEHSARDARI P, EHYAEI M A, AHMADI A,et al .Energy,exergy,economic,exergoeconomic,and exergoenvironmental (5E) analyses of a triple cycle with carbon capture[J].Journal of CO2 Utilization,2020,41:101258. doi:10.1016/j.jcou.2020.101258 |

| 21 | 刘欣旸 .燃气-蒸汽联合循环系统㶲经济性分析[D].鞍山:辽宁科技大学,2022. doi:10.1021/acsomega.1c05502 |

| Liu X Y .Exergy and exergoeconomic analyses of combined cycle power plant[D].Anshan:University of Science and Technology Liaoning,2022. doi:10.1021/acsomega.1c05502 | |

| 22 | 李浩浩,朱曙光,马晓荣,等 .燃气-蒸汽联合循环电厂节能分析[J].能源研究与利用,2022(4):27-33. doi:10.3969/j.issn.1001-5523.2022.04.006 |

| LI H H, ZHU S G, MA X R,et al .Energy saving analysis of gas-steam combined cycle power plant[J].Energy Research & Utilization,2022(4):27-33. doi:10.3969/j.issn.1001-5523.2022.04.006 | |

| 23 | BAGHERNEJAD A, ANVARI-MOGHADDAM A .Exergoeconomic and environmental analysis and multi-objective optimization of a new regenerative gas turbine combined cycle[J].Applied Sciences,2021,11(23):11554. doi:10.3390/app112311554 |

| 24 | MOHTARAM S, SUN H, LIN J,et al .Multi-objective evolutionary optimization & 4E analysis of a bulky combined cycle power plant by CO2/CO/NO x reduction and cost controlling targets[J].Renewable and Sustainable Energy Reviews,2020,128:109898. doi:10.1016/j.rser.2020.109898 |

| 25 | JAVADI M A, HOSEINZADEH S, KHALAJI M,et al .Optimization and analysis of exergy,economic,and environmental of a combined cycle power plant[J].Sādhanā,2019,44(5):121. doi:10.1007/s12046-019-1102-4 |

| 26 | HAGHGHI B, SALEH A, HAJABDOLLAHI H,et al .A combined cycle power plant integrated with a desalination system:energy,exergy,economic and environmental (4E) analysis and multi-objective optimization[J].Korean Journal of Chemical Engineering,2022,39(7):1688-1708. doi:10.1007/s11814-022-1098-z |

| 27 | 王树成,付忠广,张高强,等 .基于先进㶲分析方法的燃气-蒸汽联合循环㶲损分析[J].热力发电,2019,48(3):75-79. |

| WANG S C, FU Z G, ZHANG G Q,et al .Exergy destruction analysis of gas-steam combined cycle based on the advanced exergy analysis method[J].Thermal Power Generation,2019,48(3):75-79. | |

| 28 | PETRAKOPOULOU F, TSATSARONIS G, MOROSUK T,et al .Conventional and advanced exergetic analyses applied to a combined cycle power plant[J].Energy,2012,41(1):146-152. doi:10.1016/j.energy.2011.05.028 |

| 29 | LI T, LI X, GAO X,et al .Geothermal power generation improvement of organic Rankine flash cycle using exergy,advanced exergy and exergoeconomic analyses[J].Applied Thermal Engineering,2023,223:120032. doi:10.1016/j.applthermaleng.2023.120032 |

| 30 | 刘峰 .基于㶲分析的燃气轮机总体性能优化设计方法研究[D].北京:中国科学院大学,2021. |

| LIU F .Research on optimization design method of gas turbine overall performance based on exergy analysis[D].Beijing:University of Chinese Academy of Sciences,2021. | |

| 31 | MONTAZERINEJAD H, AHMADI P, MONTAZERINEJAD Z .Advanced exergy,exergo-economic and exrgo-environmental analyses of a solar based trigeneration energy system[J].Applied Thermal Engineering,2019,152:666-685. doi:10.1016/j.applthermaleng.2019.01.040 |

| 32 | 高金彤 .燃煤热电系统㶲经济学分析及环境影响评估[D].沈阳:东北大学,2018. |

| GAO J T .Exergy economic analysis and environmental impact assessment of coal-fired thermoelectric system[D].Shenyang:Northeastern University,2018. | |

| 33 | AMBRIZ-DÍAZ V M, RUBIO-MAYA C, RUIZ-CASANOVA E,et al .Advanced exergy and exergoeconomic analysis for a polygeneration plant operating in geothermal cascade[J].Energy Conversion and Management,2020,203:112227. doi:10.1016/j.enconman.2019.112227 |

| [1] | 王翔宇, 陈武晖, 郭小龙, 常喜强. 发电系统数字化研究综述[J]. 发电技术, 2024, 45(1): 120-141. |

| [2] | 胡可嘉, 张军, 张天宇, 高立新. 基于Matlab/Simulink仿真的H级燃机发电机静态变频启动装置谐波分析[J]. 发电技术, 2020, 41(6): 697-705. |

| [3] | 杨俊,潘晓磊,蔡龙海,张大全,朱冲,姚勇. 9F级联合循环供热机组停用保护系统设计技术方案研究[J]. 发电技术, 2020, 41(4): 391-398. |

| [4] | 翟融融,刘洪涛. 基于有限时间热力学的太阳能辅助燃煤发电系统集成理论分析[J]. 发电技术, 2019, 40(4): 316-322. |

| [5] | 王超. 结合燃气-蒸汽联合循环的液化天然气冷能发电利用[J]. 发电技术, 2018, 39(3): 263-267. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||